Method for detecting adhesive property of hollow glass external sealant

A technology of bonding performance and detection method, applied in measuring devices, instruments, mechanical devices, etc., can solve the problem that the quality of insulating glass sealant cannot be truly reflected, the safe use performance of insulating glass is affected, and the outer sealant of insulating glass is not applicable. and other problems, to achieve the effect of saving on-site test costs, easy to popularize and use, and accurate bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

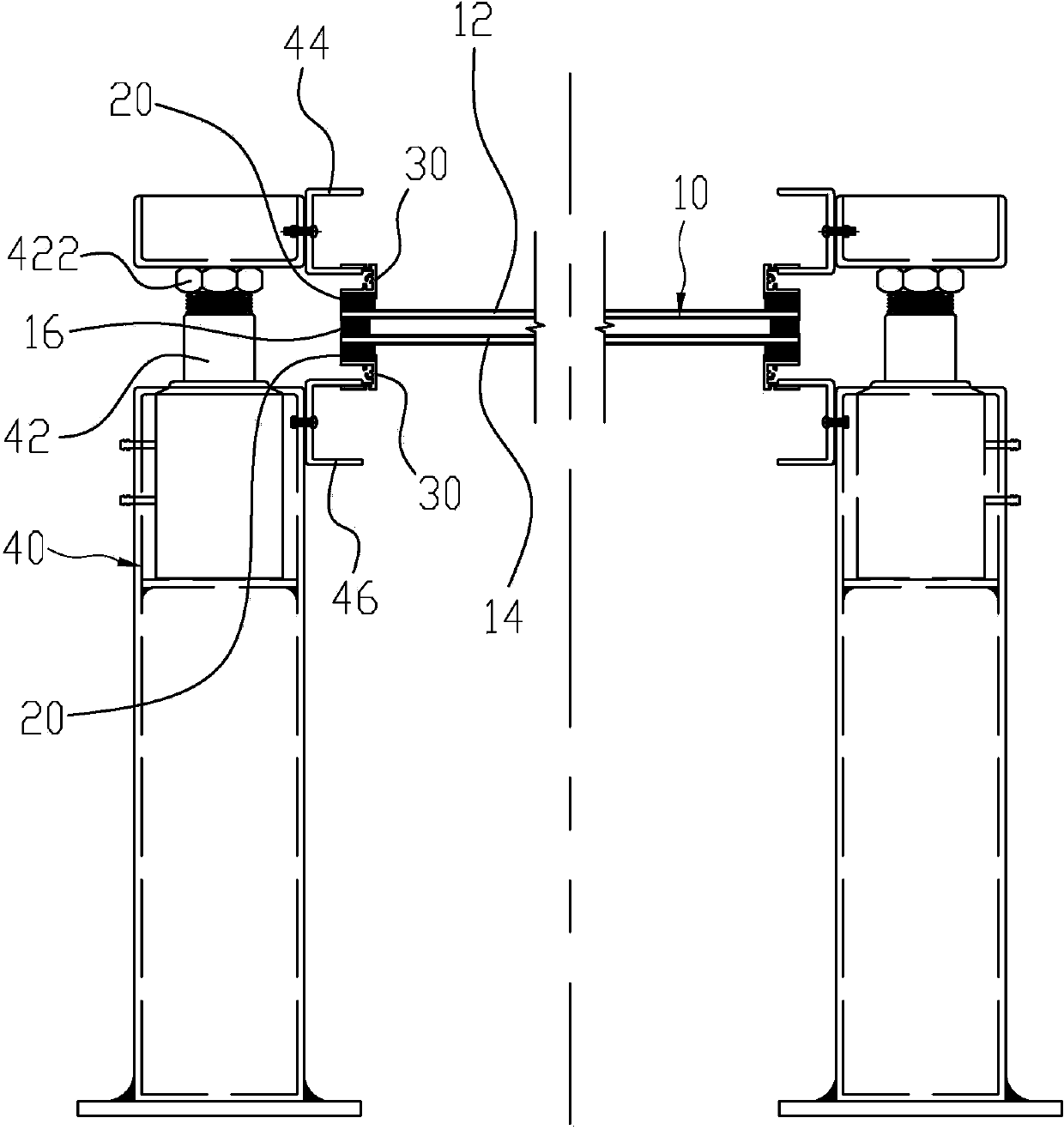

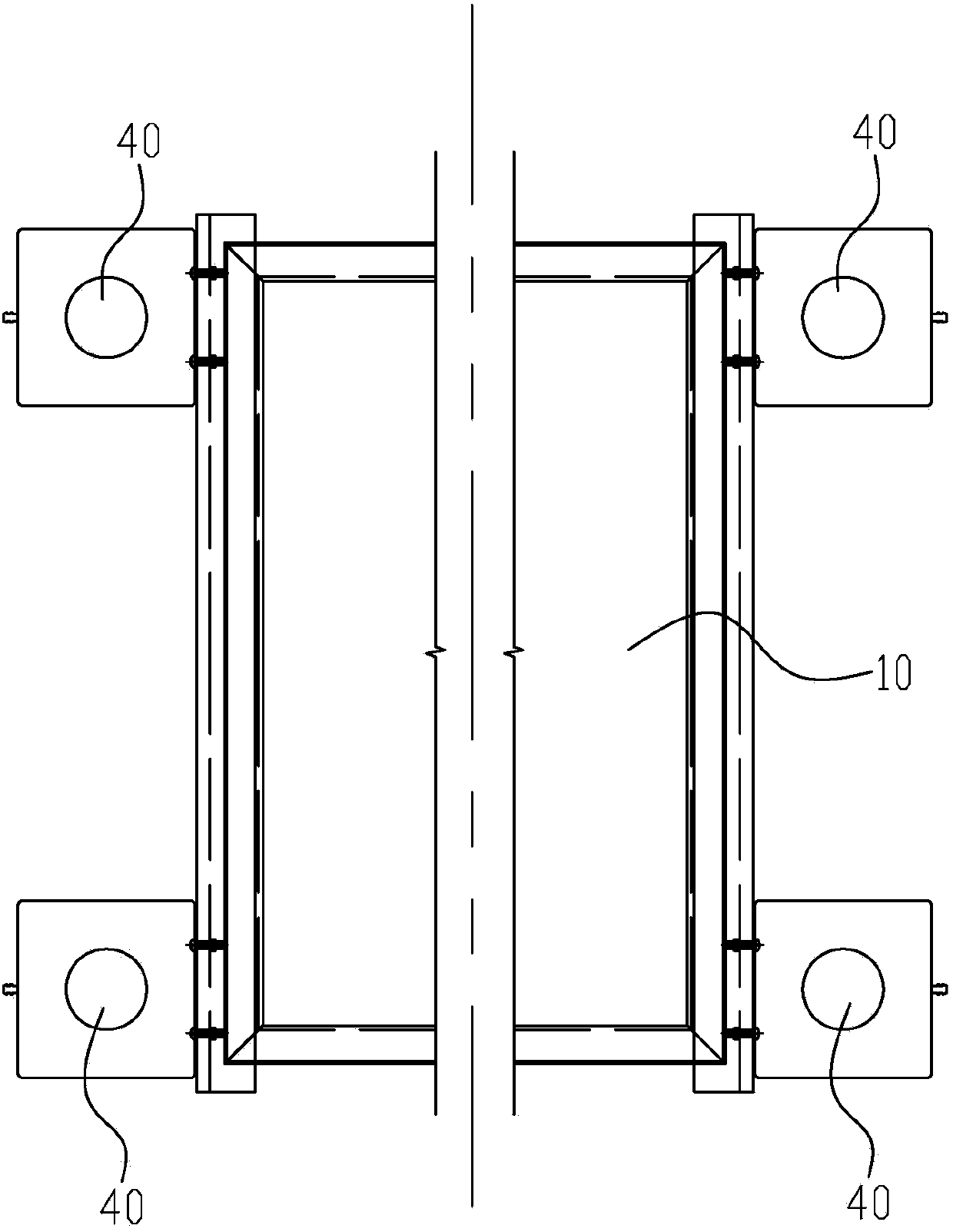

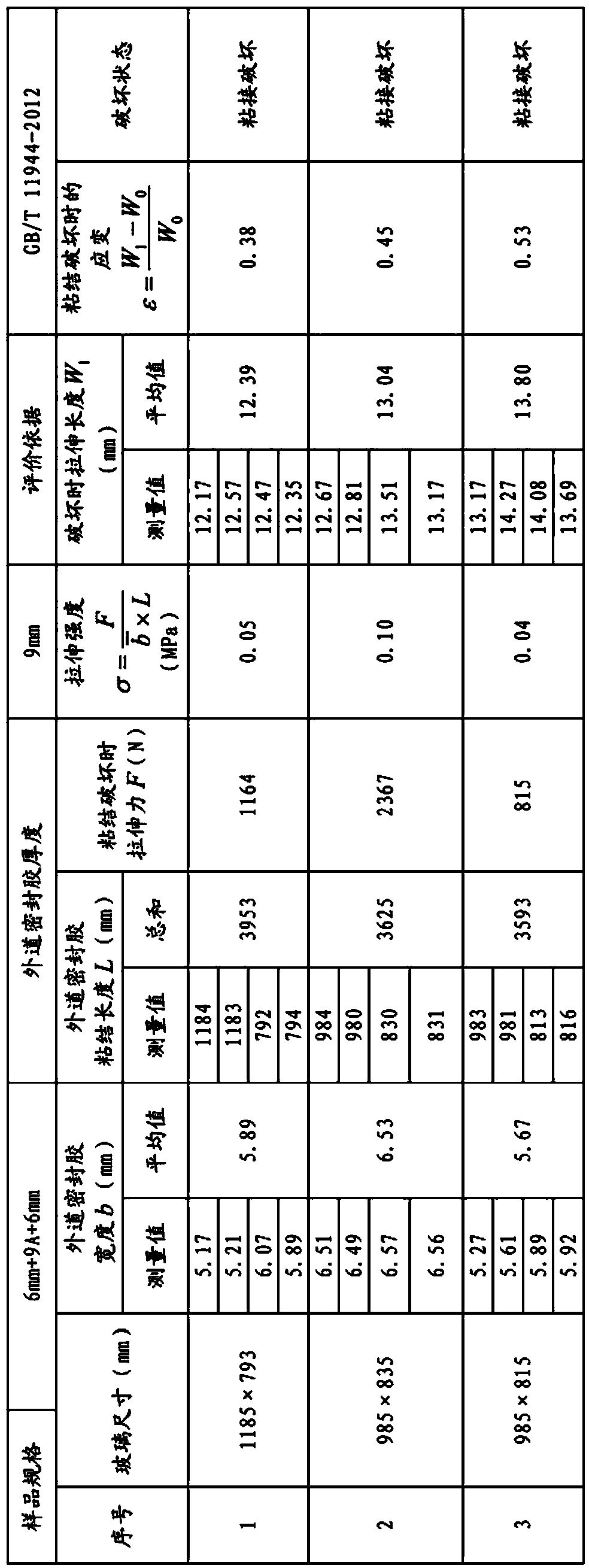

[0034] Please refer to figure 1 with figure 2 , the insulating glass 10 includes an upper glass plate 12, a lower glass plate 14, an outer sealant 16 connecting the upper glass plate 12 and the lower glass plate 14, and the outer sealant 16 is sealed and connected around the hollow glass 10 from end to end. The thickness, width and length of the outer road sealant 16 are respectively W 0 , L.

[0035] The bonding performance testing process of the outer sealant 16 includes steps:

[0036] (1) Wipe the surroundings of the upper and lower surfaces of the insulating glass 10 with a dry cloth and absolute alcohol to remove dust and grease on the upper and lower surfaces of the insulating glass 10 . Adhesives 20 are used to bond a secondary frame 30 to the symmetrical sides of the upper and lower surfaces of the insulating glass 10 . The adhesive 30 is preferably a silicone structural adhesive with a tensile bond strength ≥ 0.60 MPa. The sub-frame 30 is preferably arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com