Remote air compressor monitoring system based on internet of things

A remote monitoring system, air compressor technology, applied in the direction of electrical program control, comprehensive factory control, comprehensive factory control, etc. Without problems such as air compressor related information, it can achieve significant practical value, efficient online operation and maintenance services, and reduce service costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

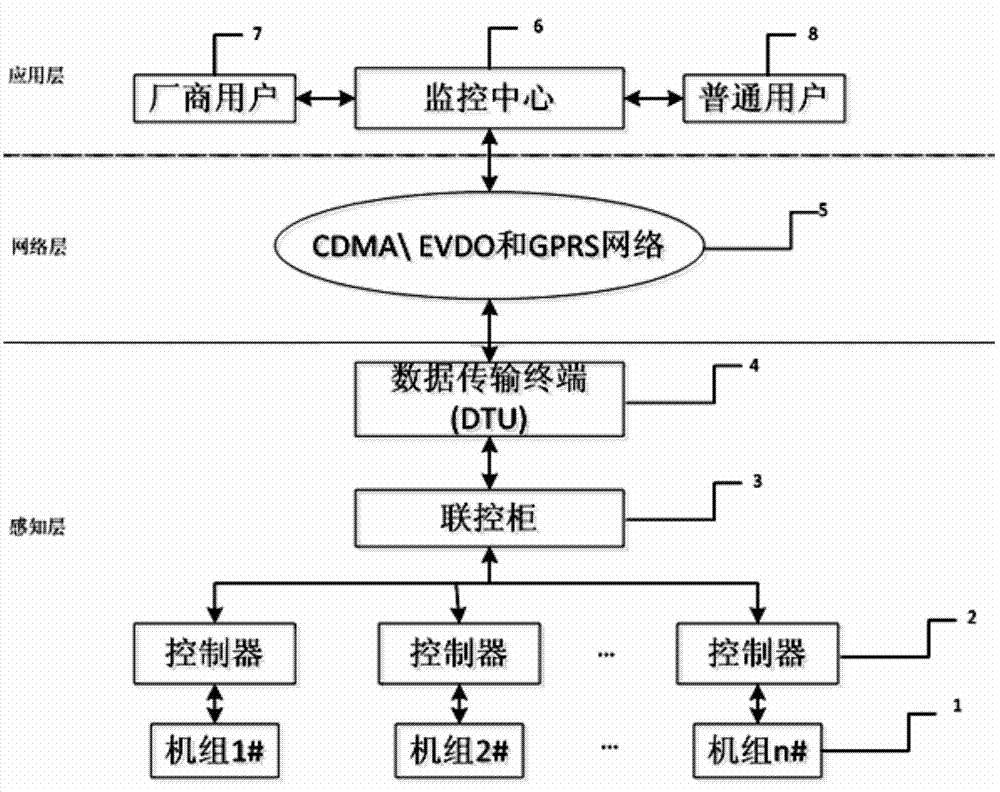

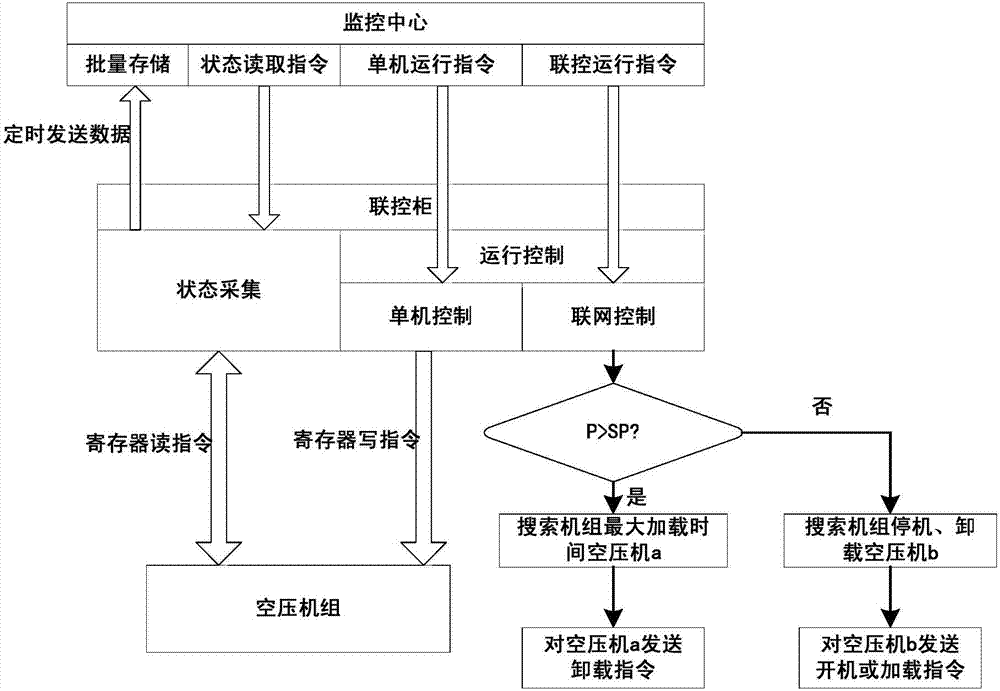

[0023] Such as figure 1 As shown, a kind of air compressor remote monitoring system based on the Internet of Things provided by the present invention includes a three-layer structure of the Internet of Things: a perception layer, a network layer and an application layer, and the perception layer collects the real-time operation of the bottom air compressor The data is transmitted to the application layer through the wireless network layer. The application layer includes the monitoring center 6, manufacturer users 7 and ordinary users 8. Manufacturer users 7 and ordinary users 8 log in to the monitoring center 6 to read the data of the lower air compressor unit 1 in real time. And issue a running command to control the loading, unloading, starting or stopping of the lower air compressor unit 1.

[0024] The perception layer includes an air compressor unit 1 and its corresponding PLC controller 2, a joint control cabinet 3 and a data transmission terminal DTU 4, the PLC controll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com