A waveguide based on multi-layer printing technology and its preparation method

A multi-layer printing and waveguide technology, which is applied in the direction of waveguides, waveguide devices, printed circuit components, etc., can solve the problems of high process requirements, difficult integration of metal waveguides, and difficult implementation, so as to save metal resources and avoid The problem of mechanical connection and the effect of simplification of processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The above-mentioned method for preparing a waveguide based on multi-layer printing technology includes the following steps:

[0037](1), set the broadside length a and height b of the metal waveguide;

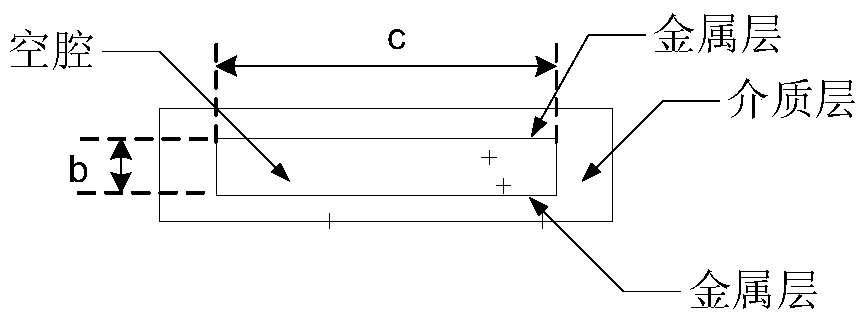

[0038] (2) Select m-layer flat printed boards as the dielectric substrate group, wherein m is a positive integer and m≥3; the m-layer flat printed boards are sorted from top to bottom as the first layer to the mth layer, wherein the first The total thickness of the planar printed boards from the 2nd layer to the m-1th layer is equal to the height b of the metal waveguide set in the step (1);

[0039] (3), metal coating is carried out on the lower surface of the first layer of flat printed board and the upper surface of the mth layer of flat printed board;

[0040] (4), adopt multi-layer PCB or LTCC process to process the flat printed board of the 2nd layer~m-1 layer, form a cavity between the two layers of metal coating layers obtained in step (3), The length of the na...

Embodiment

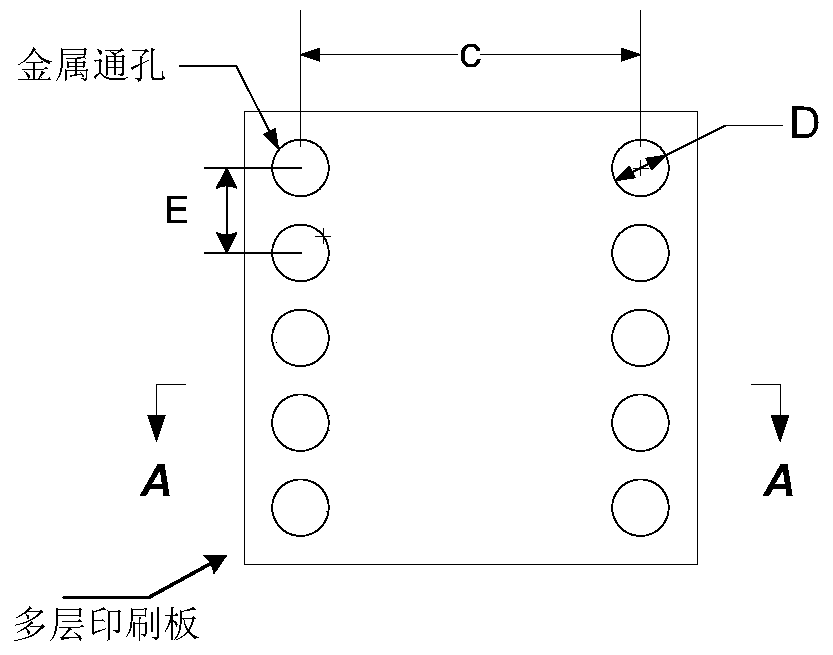

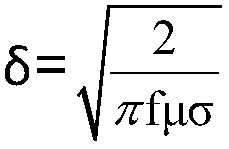

[0047] The working center frequency of the waveguide is f=14GHz, and m-layer flat printed boards are used as the dielectric substrate group. Among them, the total thickness of the flat printed boards from the second layer to the m-1th layer is 7mm, and the lower surface of the first layer of flat printed boards and There is a metal coating layer on the upper surface of the mth layer of the flat printing plate, and the thickness of the metal coating layer is 7um; the length of the narrow side of the cavity between the two metal coating layers is 7mm, and the length c of the wide side is 14mm; Metal through-holes are provided on the surface of the board, and the metal through-holes pass through the m-layer planar printing plate, and the metal through-holes are distributed in two rows in parallel on the surface of the planar printing plate, and the distribution direction is perpendicular to the width direction of the cavity , wherein the diameter of the metal vias D=0.4mm, the cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com