Electric temporary lapping joint device applied to 10kV distribution network

A distribution network, temporary technology, applied in the field of distribution network, can solve the problem of low reliability of power supply, achieve the effect of shortening the interruption time, convenient placement, improving service quality and reliability of power supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

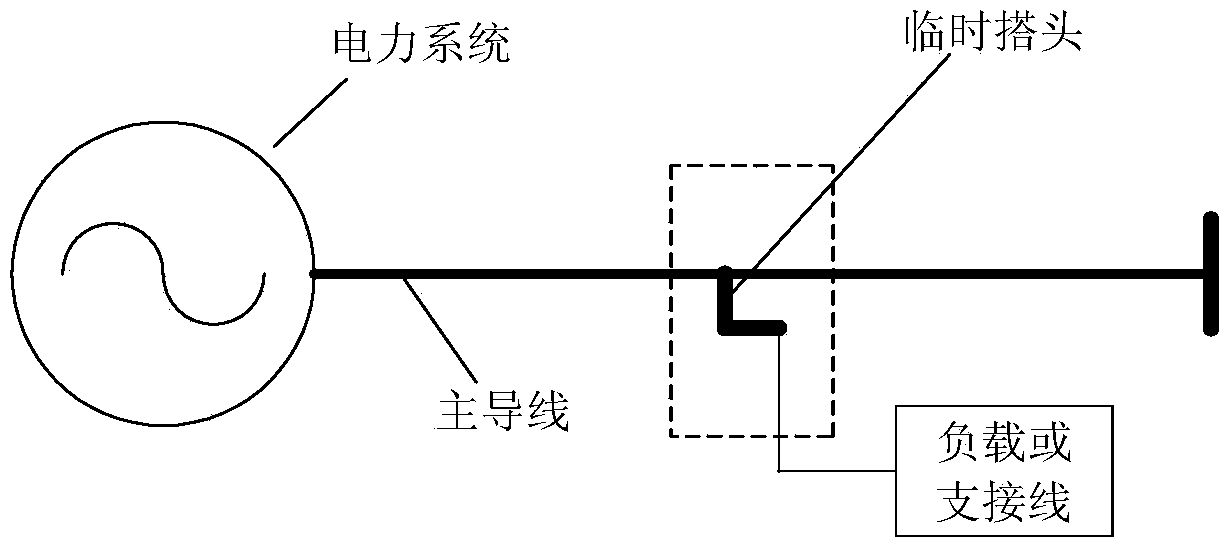

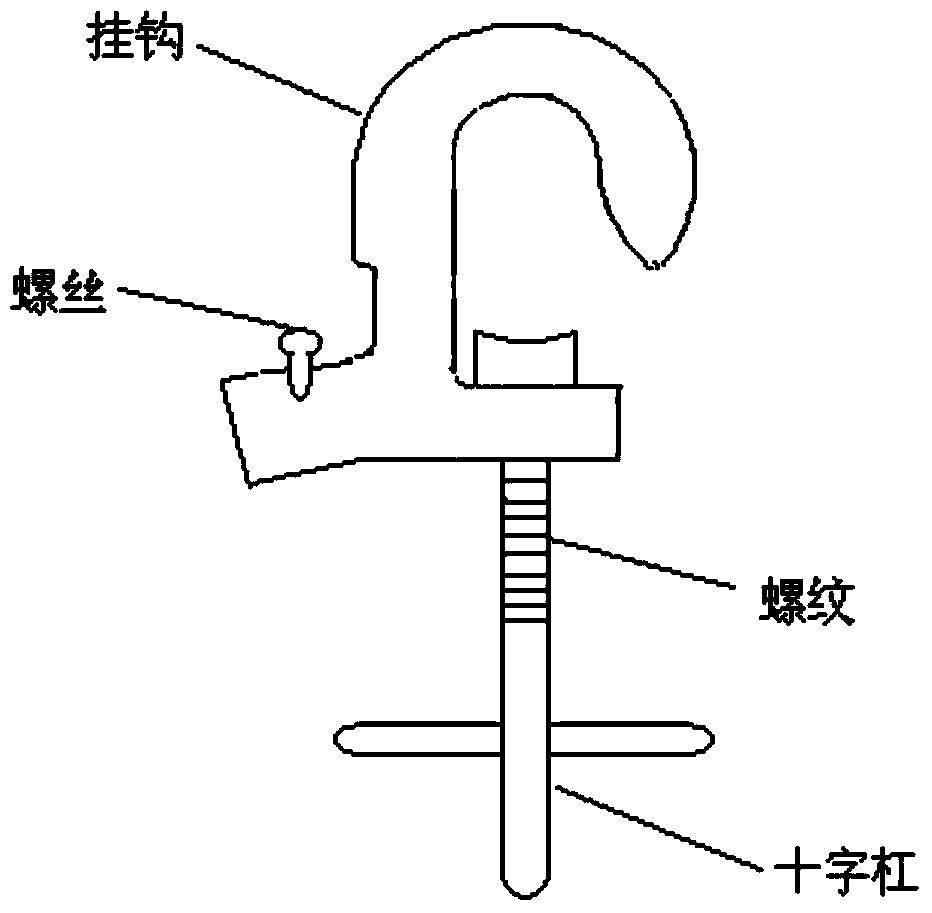

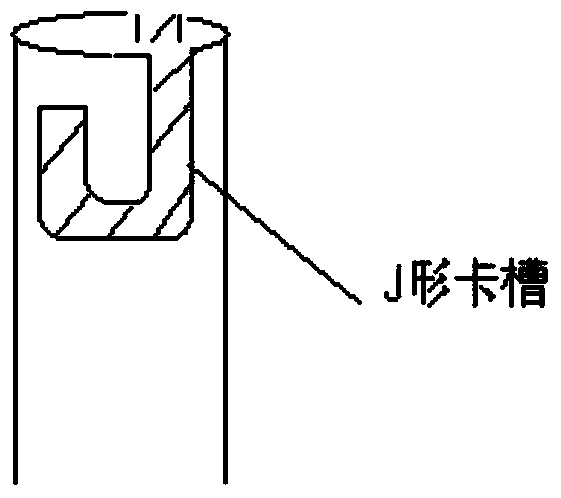

[0022] Such as figure 1 and figure 2 As shown, the temporary bonding device of the present invention is used to carry out live bonding operations on the main wires and lead wires of the power system in rainy days, so as to realize the normal operation of the load. The temporary bonding device includes temporary bonding and insulation operations Rod, the part where the temporary lap is used to fix the main wire is a hook structure, and the part where the temporary lap is connected to the lead joint is provided with a threaded hole, and the temporary lap and the lead joint are connected by screws. The threaded holes are used for fixing, and the part where the temporary lap is used for fixing with the insulating operating rod is a cross bar structure, the head end of the cross bar structure is a thread, and the tail end of the cross bar structure is "ten". Glyph structure, the head end of the cross bar is connected to the hook structure through threads, the "ten" shaped structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com