Electric connector with connecting nut

A technology for connecting nuts and electrical connectors, applied in the parts of connecting devices, devices for connecting and connecting/disconnecting connecting parts, etc., can solve problems such as failure, opening of circlips, and easy falling off of circlips.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

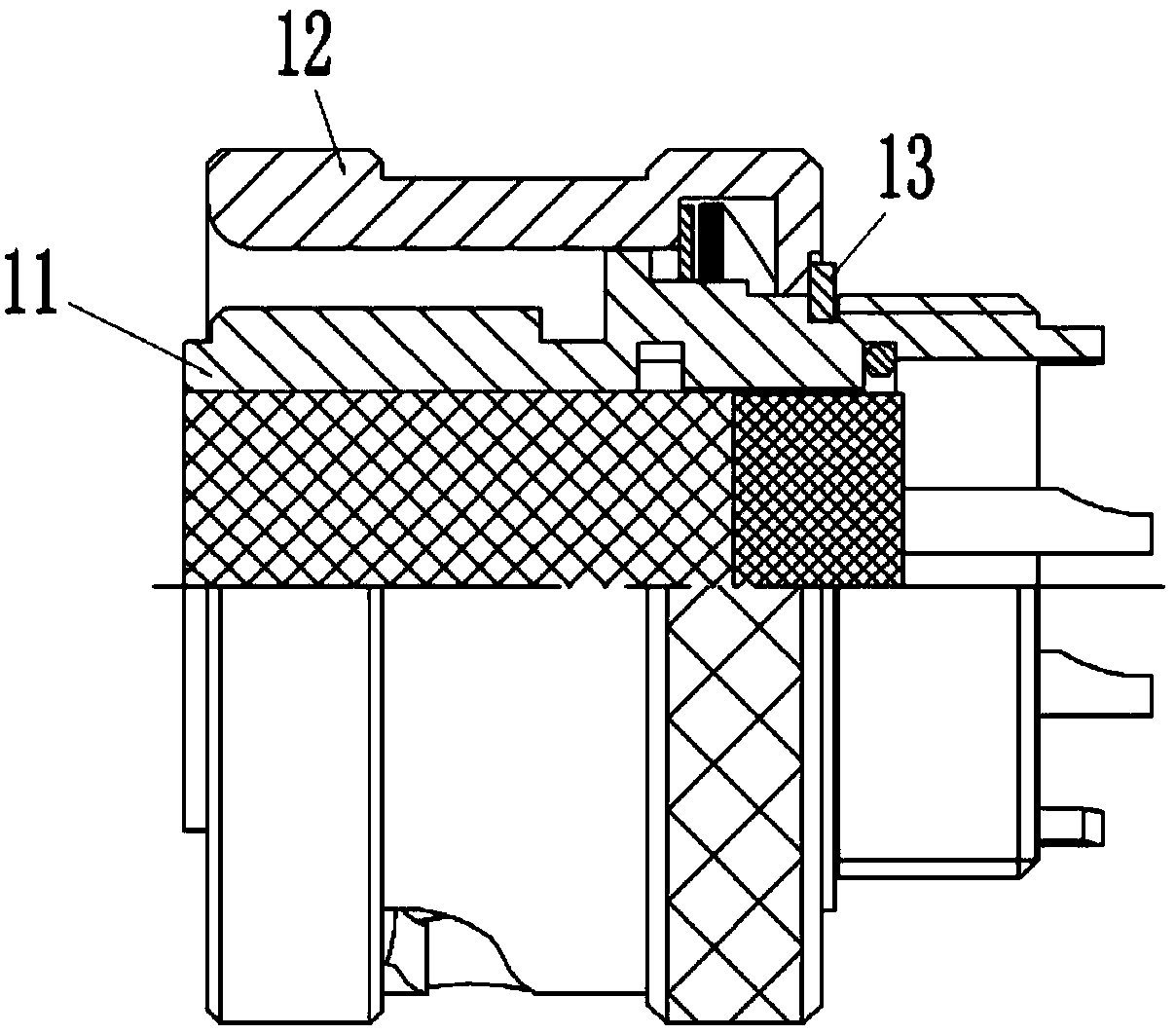

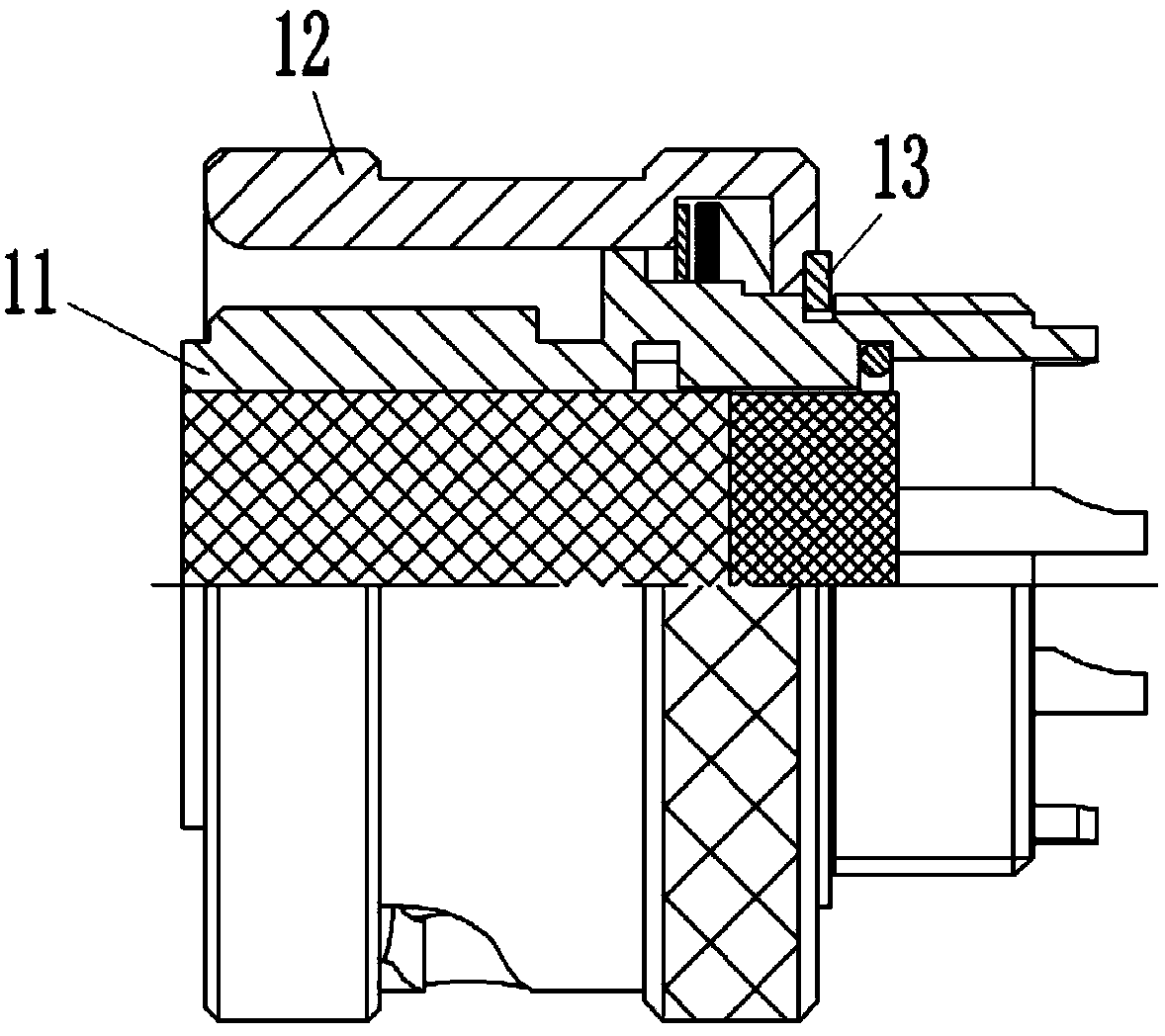

[0013] Embodiments of electrical connectors with connection nuts, such as Figure 1-2 As shown, the electrical connector has a front end as a plug-in end, and includes a housing 11 and a connecting nut 12 rotatably assembled on the housing 11 .

[0014] The middle part of the housing 11 is provided with a protruding ring structure protruding to the periphery, and the rear side of the protruding ring structure forms a rear-facing stepped surface on the housing, which can prevent the connecting nut 12 from The front end of the housing falls off forward.

[0015] The rear end of the connecting nut 12 is provided with an inturned edge, which is matched with the protruding ring on the housing 11 through the inturned edge. In addition, the outer peripheral surface of the housing 11 is also provided with a There is a circlip groove, and a circlip 13 (C-shaped, also called a circlip) is clamped in the circlip groove, and the circlip 13 can cooperate with the inversion edge of the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com