Fan motor stator and manufacturing method

A technology of fan motor and manufacturing method, which is applied in the field of fan motor stator manufacturing, can solve the problems of high production cost, many enameled wires, and great difficulty, and achieve the effects of simple manufacturing process, reduced metal consumables, and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is described in further detail by the following examples.

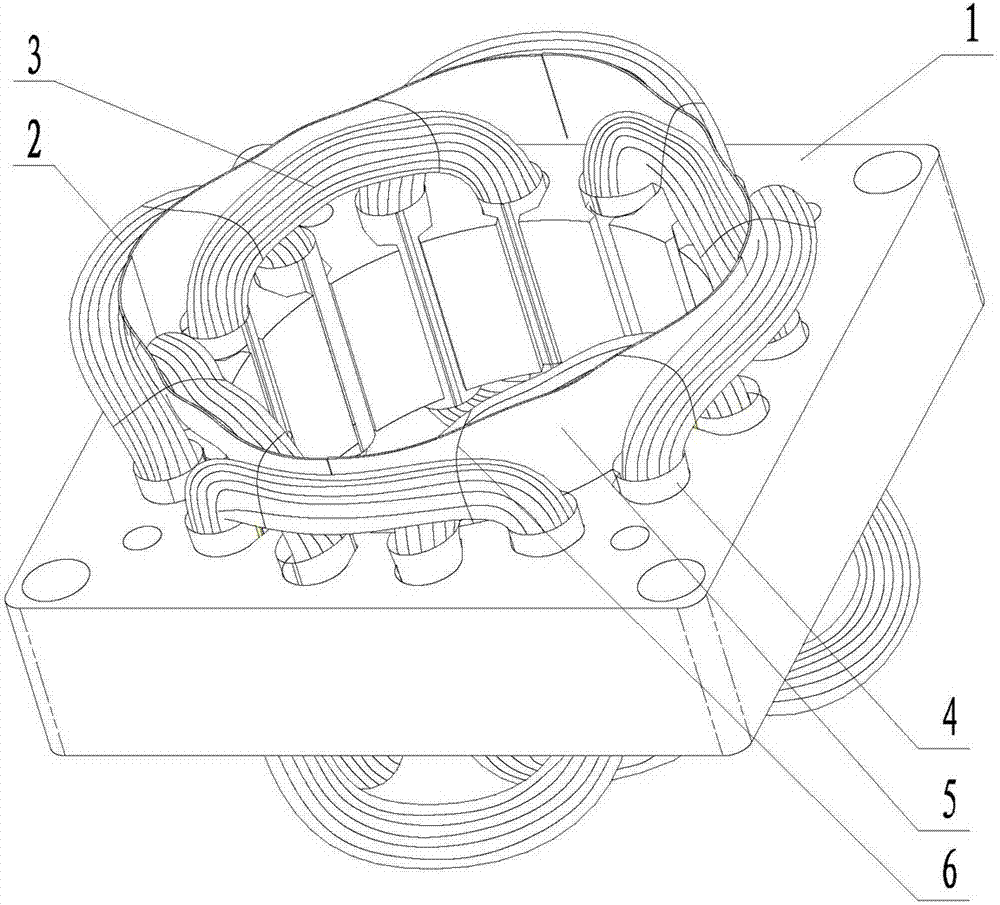

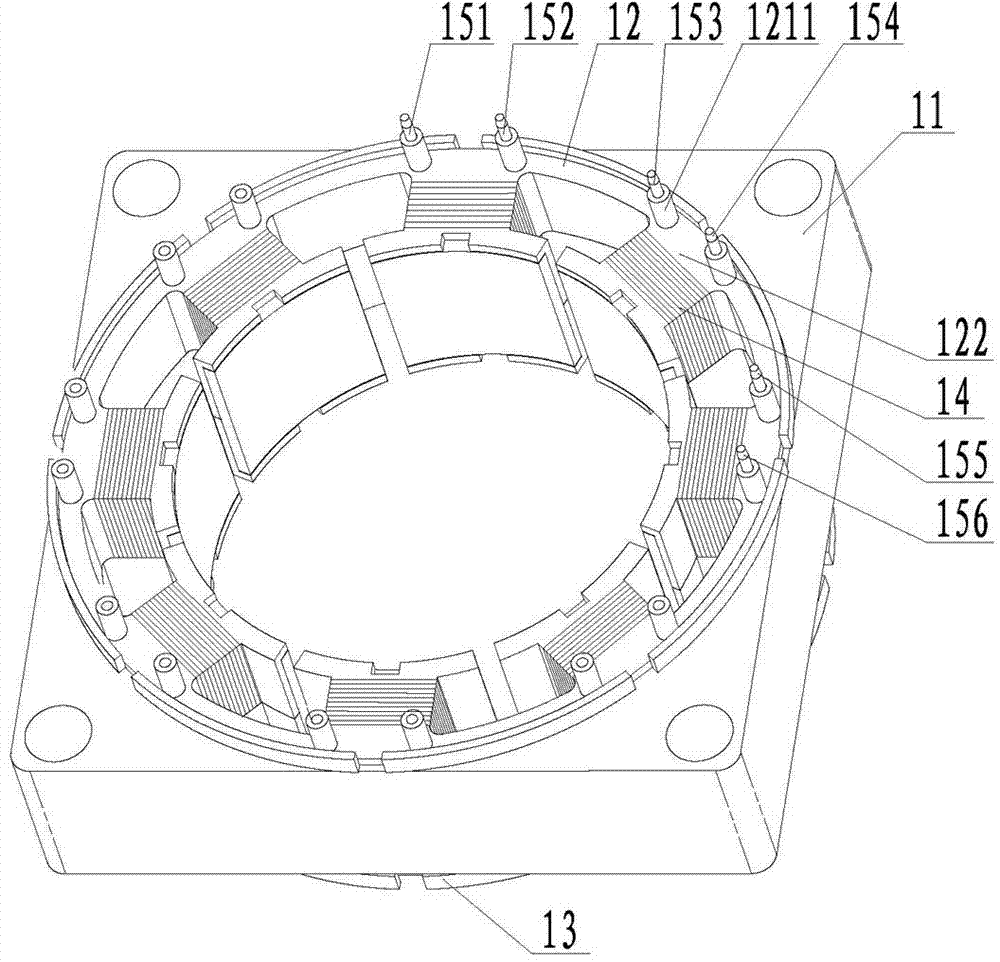

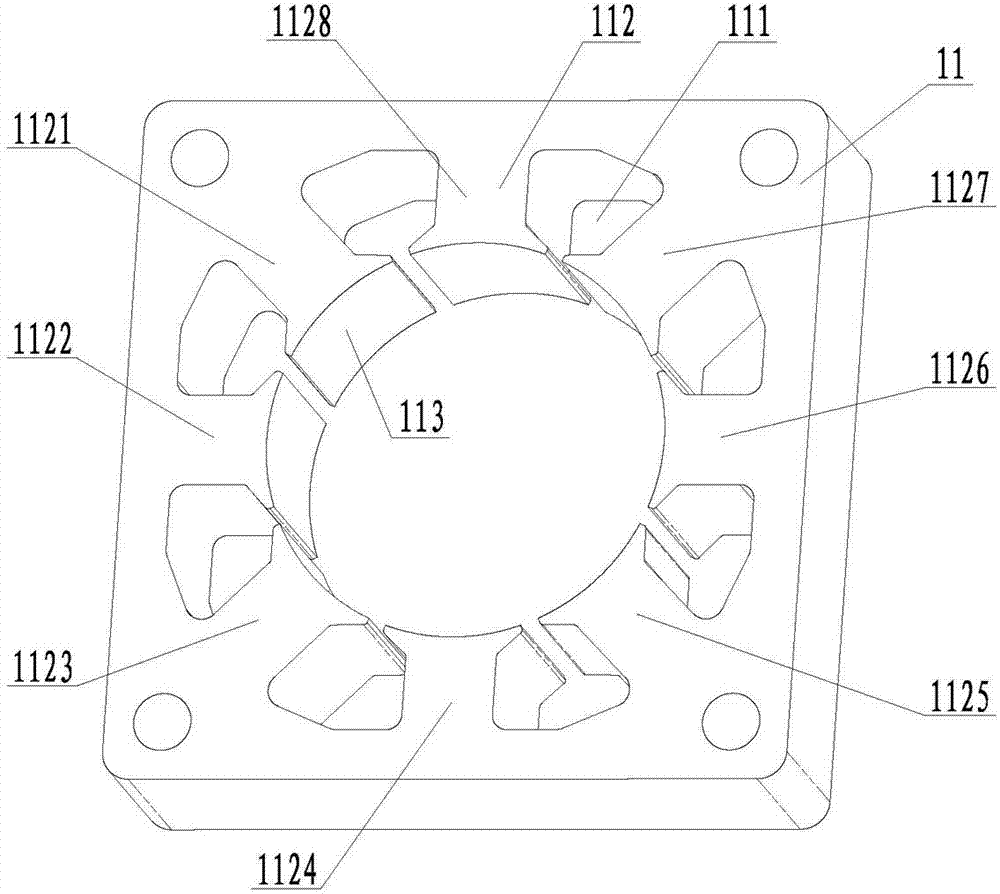

[0033] see Figure 2-Figure 12 As shown, a fan motor stator is mainly composed of a stator core 11, an upper frame 12, a lower frame 13, a main winding 141 and three auxiliary windings. The main and auxiliary windings 14 include the main winding 141 and three auxiliary windings. The main and auxiliary windings 14 are connected in parallel with capacitors C. The stator core 11 is evenly arranged along the ring circle with 8 iron yokes 112, 8 pole shoes 113 and 8 wire slots. 111, each slot 111 is fan-shaped and has a relatively large cross-sectional area, each iron yoke 112 is square, and the intersecting angle between the center lines of two adjacent iron yokes 112 is 45°. It is also provided with an upper frame 12 and a lower frame 13 that are matched with each other. The lower part of the annular upper plate 125 of the upper frame 12 is evenly provided with 8 fan-shaped upper hollow groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com