Cleaning equipment and processing method of easily damaged vegetables

A cleaning equipment and vegetable processing technology, which is applied in the field of food processing, can solve the problems of large-scale, standardized processing, and large waste of water resources and low degree of removal of impurities in rubber barrel rinsing, so as to achieve uniform force and clean Thoroughly improve the effect of production and processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Bamboo Bird's Nest

[0062] (a) Harvest raw materials on time and with high standards: Check the growth status of bamboo bird's nest in advance to lock in the best timing for harvesting.

[0063] (b) Low-temperature quick-freezing preservation: the harvested raw materials are divided into breathable woven bags of no more than 40 catties each, and when they are flattened so that the thickness does not exceed 15 cm, they are sent to a -28° freezer for low-temperature quick-freezing. Refrigerate and keep fresh at -18° until processing. The time interval between harvest and quick freezing should not exceed 10 hours. After entering the freezer until the temperature of the whole bag of bamboo bird's nest drops to -20°, the time should not exceed 10 hours.

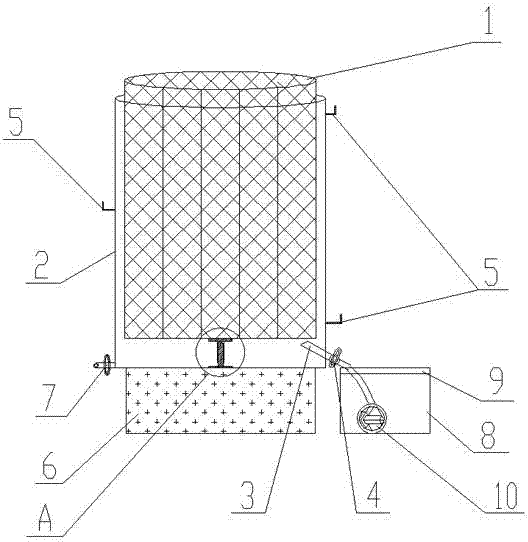

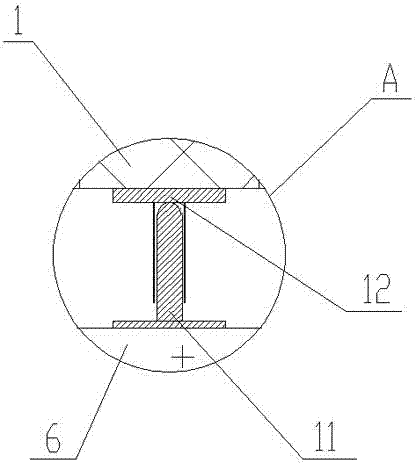

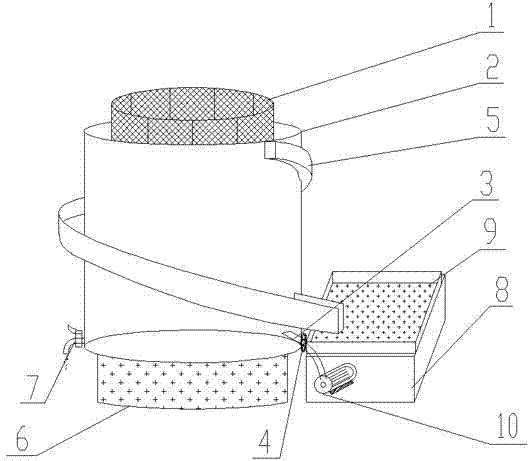

[0064] (c) Pre-washing: Use the above-mentioned vulnerable vegetable cleaning equipment to perform preliminary pre-washing on the bamboo bird's nest after it has been thawed out of the warehouse to wash out most of the smal...

Embodiment 2

[0073] Morel

[0074] (a) Raw materials are harvested on time and with high standards: Harvest on time and with high standards according to the morel production season.

[0075] (b) Low-temperature refrigeration and preservation: If morel mushrooms cannot be cleaned in time after harvesting, they should be divided into bamboo baskets of no more than 40 catties per frame, and placed in a refrigerator at 0-5°C. When cleaning, they are numbered according to the order of storage, and the ones with the earlier storage date are prioritized for cleaning.

[0076] (c) Pre-washing: Use the above-mentioned fragile vegetable cleaning equipment to perform preliminary pre-washing on the morels leaving the warehouse to clean out most of the small insects and impurities. The initial washing time is controlled within 5 minutes, using 75ppm pure water, and the naked eyes can see that the impurities in the pre-washed morels are significantly reduced in the rotating inner bucket.

[0077] (d) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com