Pressure filter

A technology of filter press and filter press, which is applied in the fields of filtration and separation, separation methods, chemical instruments and methods, etc., can solve the problems of easy breakage, frequent use of filter presses and filter press cloths, and low solid-liquid separation efficiency. Achieve the effect of improving efficiency and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

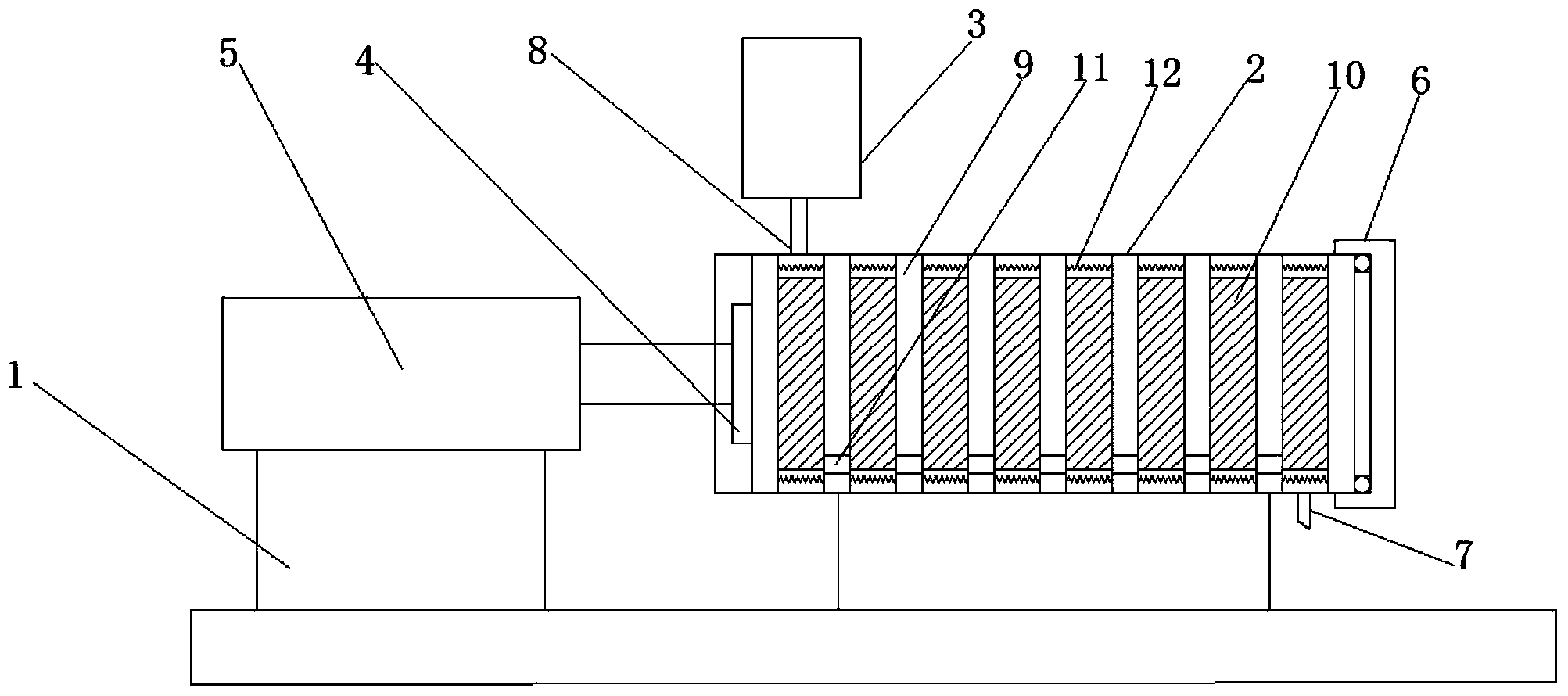

[0011] refer to figure 1 A kind of filter press shown, it comprises support 1, the cylindrical airtight container 2 that is horizontally arranged on support 1, feed pump 3, filter press plate 9 assemblies, pressing plate 4 and hydraulic cylinder 5, the airtight container 2 The right end is provided with a sealing cover 6, and the lower part of the airtight container 2 is provided with a water outlet 7 near the right end, and the upper left part of the airtight container 2 is provided with a feed port 8, which is connected to a feed pump 3. The pressure plate 4 is arranged at the left end inside the airtight container 2, and the push rod of the hydraulic cylinder 5 penetrates into the airtight container 2 and is fixedly connected with the pressure plate 4. The described filter plate 9 assembly includes a plurality of circular filter plates 9 adjacent to each other. Press filter cloth 10 is filled between the filter press plates 9, and each filter press plate 9 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com