Magnetic powder water mill with rotary pieces

A technology of water mill and rotary disc, which is applied in the field of magnetic sensing, can solve the problems of reducing production efficiency, polluting the working environment, and taking a long time, and achieves the effect of accelerating the collision friction speed and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

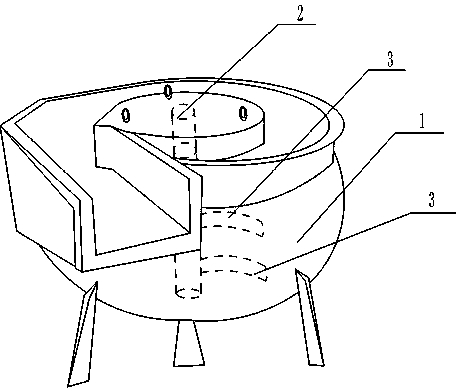

[0017] see figure 1 As shown, the magnetic powder water mill provided with the rotor in this embodiment includes a container 1 and a water mill rubber wheel 2, the water mill rubber wheel 2 is arranged in the center of the container, and the bottom end of the water mill rubber wheel 2 is in contact with the bottom inner wall of the container 1 Connected, the side wall of the hydrorubber wheel 2 is provided with a plurality of rotating pieces 3 . The water mill rubber wheel rotates under the action of the motor to drive the magnets and grinding balls in the container to run in the container. During the production process, it is necessary to add magnets, grinding balls and water to the container continuously. Due to the magnets and grinding balls The weight of the ball itself will gradually settle to the bottom of the container in the container, and the balls and magnets are driven by the rotor to prevent the balls and magnets from concentrating on the bottom of the container, s...

Embodiment 2

[0019] see figure 1 As shown, on the basis of Embodiment 1, the rotating piece 3 in this embodiment has an arc-shaped sheet structure. There are three rotating pieces 3, which are distributed on both sides of the water mill rubber wheel 2 in a staggered manner. The concave arc surface of the rotating piece 3 extends in the same clockwise direction from the end close to the rubber wheel 2 . Adjacent rotating pieces 3 have the same distance. The shape of the rotor is set so that the resistance of the millstone and magnet in the container to the rotor is reduced directly. The millstone and magnet can rotate along the arc of the rotor. promote. When the position of the rotary piece is set, the rotary piece can push the grinding stones and magnets around the water grinding rubber wheel in the container, so as to avoid the phenomenon of uneven force applied to various parts of the container. The direction of the inner concave surface of the rotor is set so that the rotor rotates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com