High quality steel continuous casting protection casting device

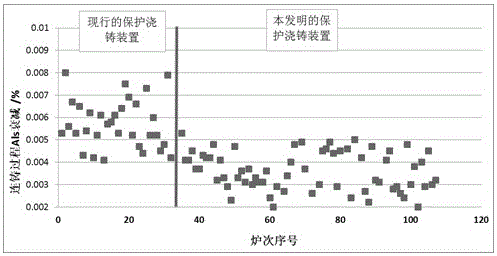

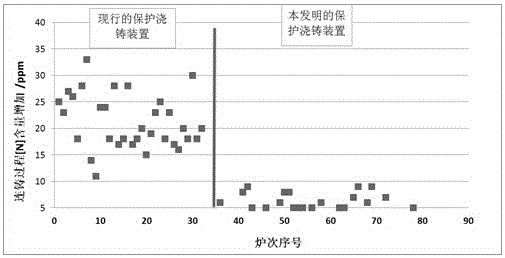

A high-quality, continuous casting technology, applied in casting equipment, casting melt containers, metal processing equipment, etc., can solve the problems of uneven distribution of argon gas, low utilization rate of argon gas, poor argon sealing effect, etc., to achieve enhanced argon Sealing and sealing effect, improving the quality of molten steel, ensuring the effect of smooth progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the examples.

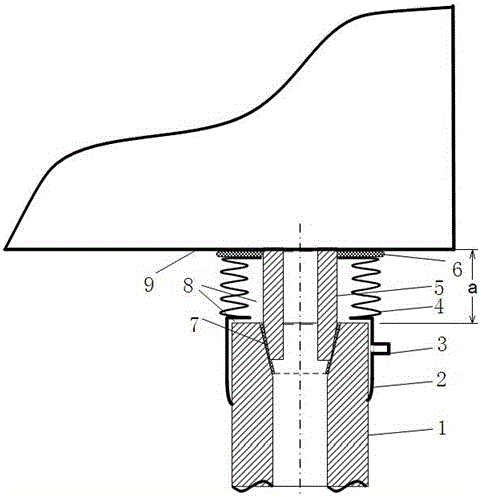

[0019] Depend on figure 1 It can be seen that the high-quality steel continuous casting protection casting device includes a ladle 9, a nozzle 5 and a shroud 1, the nozzle is placed under the tapping hole of the ladle, the nozzle is connected to the shroud, and an iron shell is arranged at the upper end of the shroud 2. An argon gas inlet 3 is provided on the side of the iron shell, and an elastic bellows 4 is arranged on the iron shell. The bellows surrounds the water outlet, and the upper end of the bellows is provided with a ring-shaped asbestos gasket 6, which leans against the bottom of the ladle and is opposite to the tapping hole. The contact part between the steel ladle and the bellows is sealed; the conical asbestos sealing ring 7 is set at the connecting part of the water inlet and the long nozzle to seal it. Argon airtight chamber 8. It is fully sealed with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com