Jig and method for welding single tubes of single-phase photovoltaic grid-connected inverter

A welding jig and inverter technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of reduced installation reliability, and achieve the effect of high reliability, high installation and positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

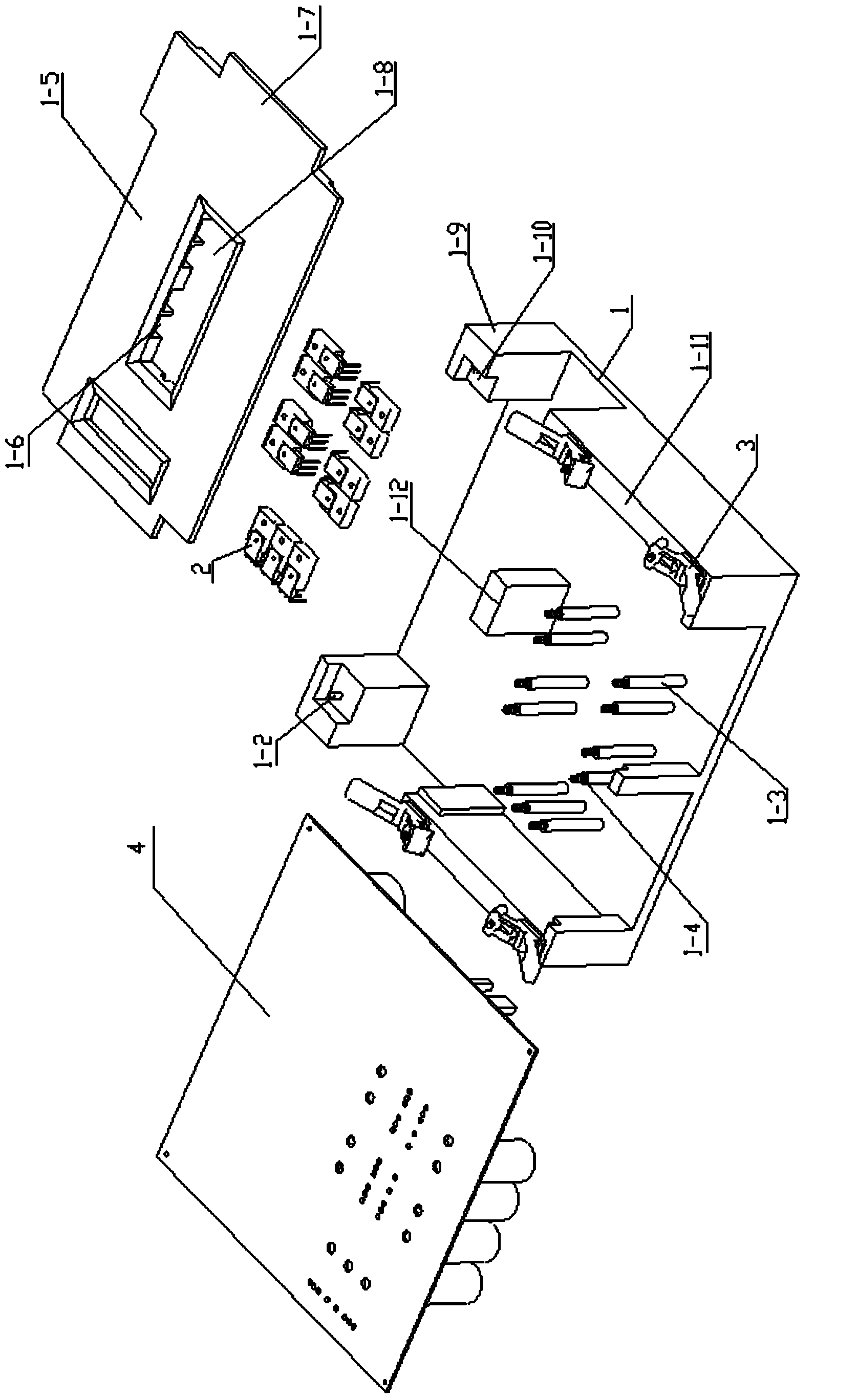

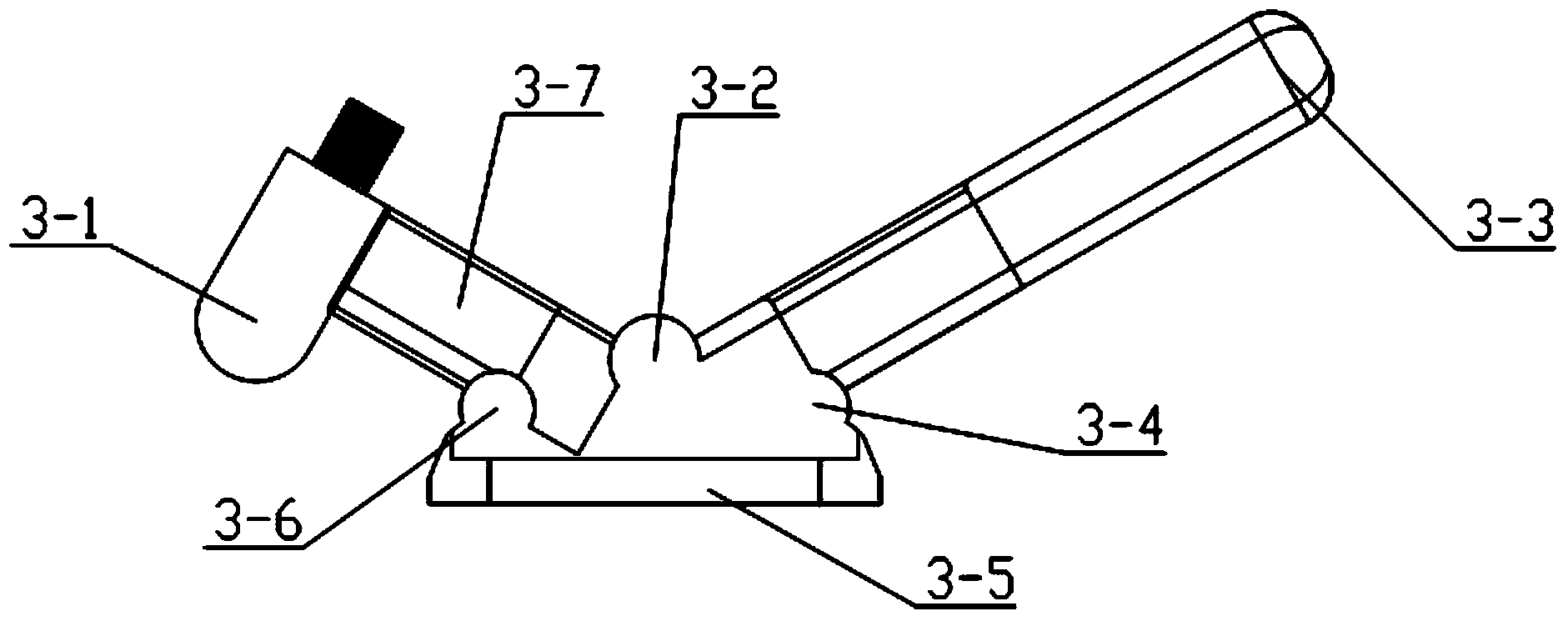

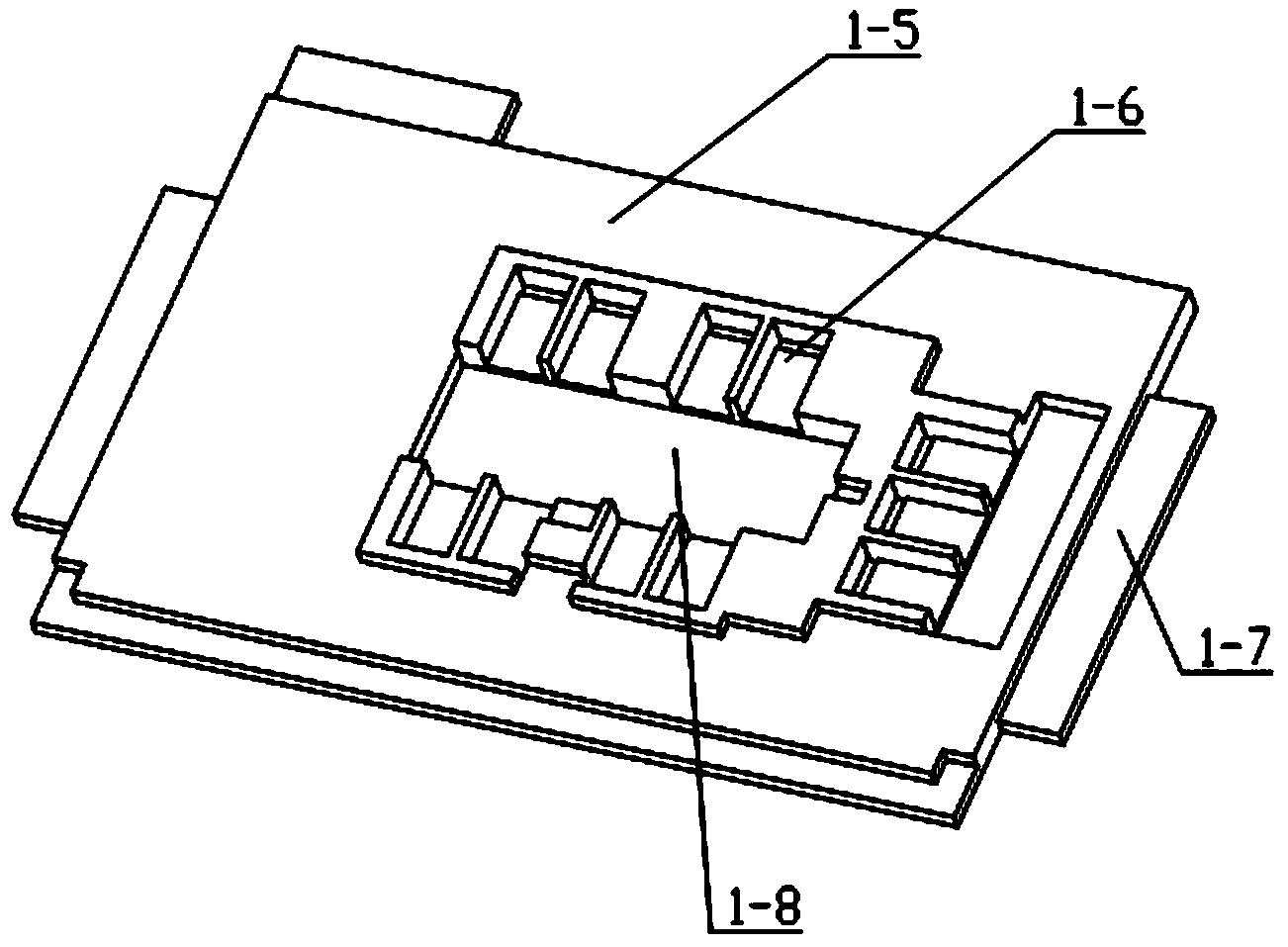

[0026] see figure 1 and image 3 As shown, this embodiment provides a single-tube welding jig for a single-phase photovoltaic grid-connected inverter, including a jig body 1, a positioning device installed on the jig body 1 for fixing the main power board 4, and located on The pressing mechanism for pressing the main power board 4 on the positioning device, the pressing mechanism includes a single-tube pressing plate 1-5, a locking assembly for pressing the single-tube pressing plate 1-5 on the positioning device, And the pressure tube vacancies 1-8 provided on the single tube pressure plate 1-5, and the multiple pressure tube placement grooves 1-6 arranged inside the single tube pressure plate 1-5, and the multiple pressure tube placement grooves 1 -6 is arranged around the vacancies 1-8 of the pressure pipe.

[0027] The main principle of the single-tube welding jig of the present invention is: fix the main power board 4 through the positioning device, then place the singl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com