Single-pipe welding jig for three-phase photovoltaic grid-connected inverter

A technology for welding jigs and inverters, applied in photovoltaic power generation, welding equipment, auxiliary welding equipment, etc., can solve the problems of poor installation position and installation accuracy, and achieve the effects of improving accuracy and simple and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

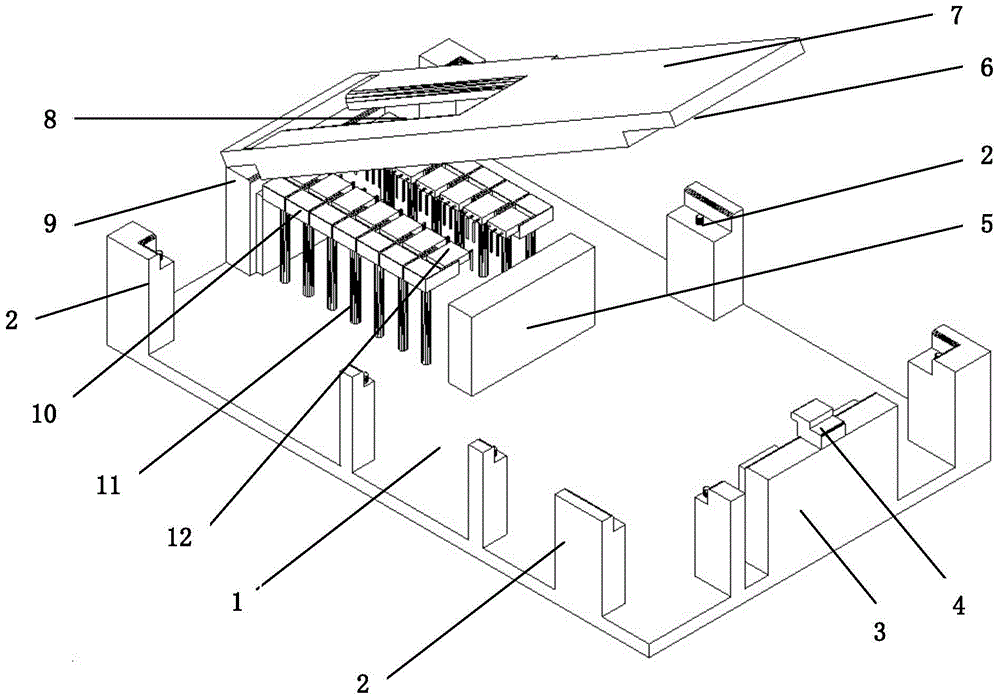

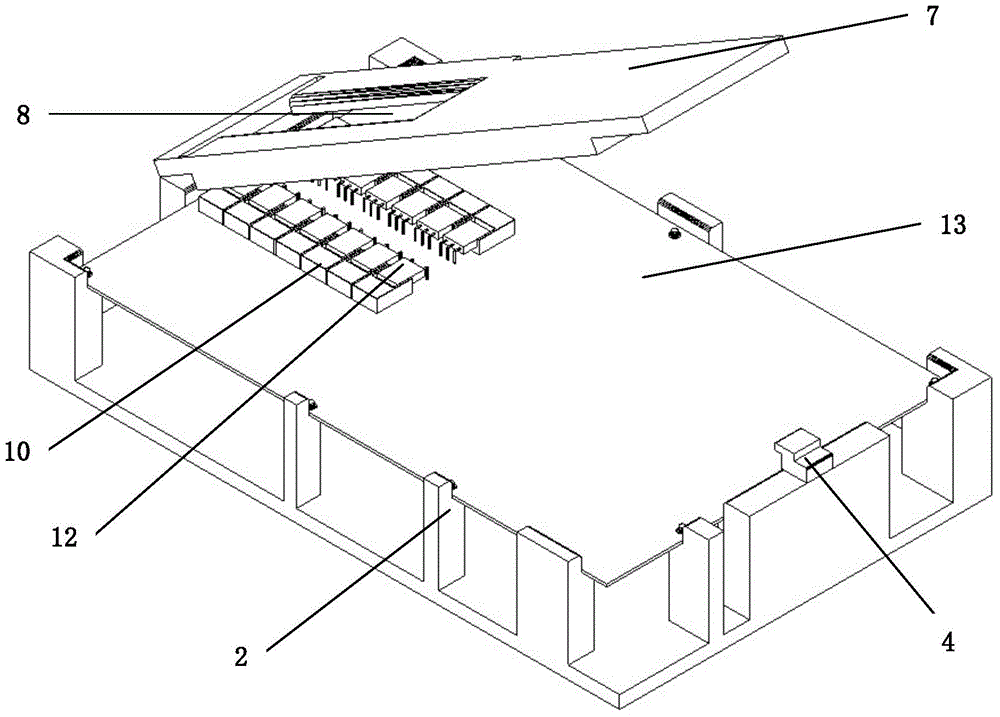

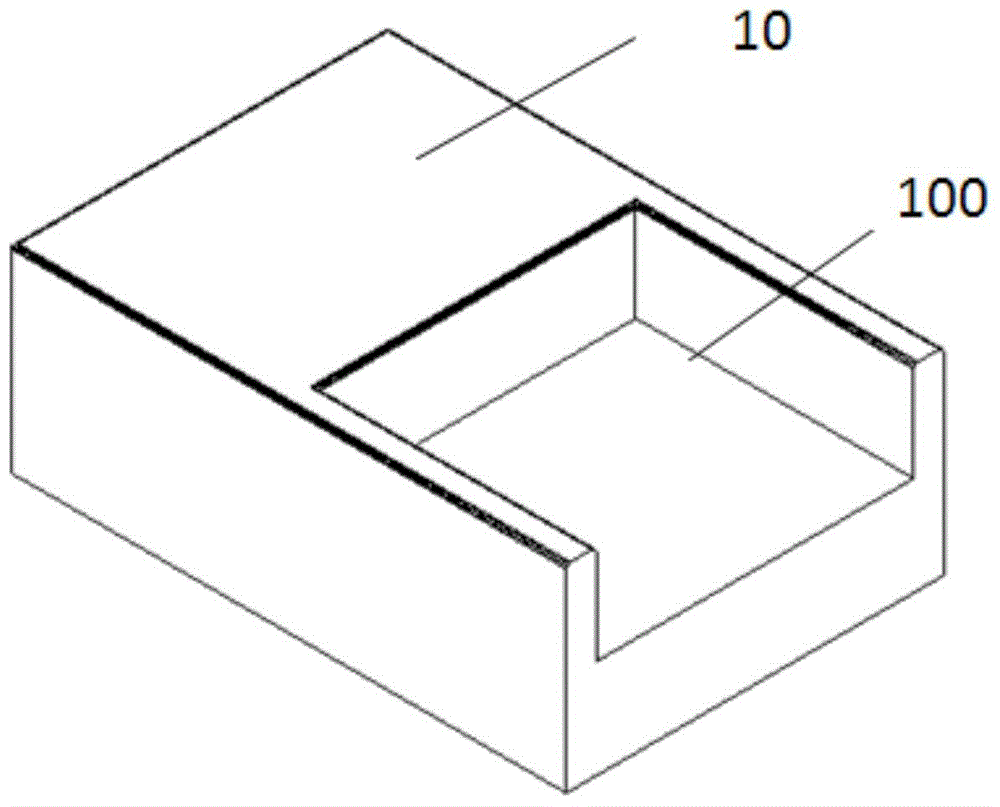

[0024] refer to figure 1 and figure 2 As shown, a single-tube welding jig for a three-phase photovoltaic grid-connected inverter provided by the present invention includes a bottom plate 1, a movable plate 7 mounted on the bottom plate 1 that is rotatable at one end, and a movable plate 7 mounted on the bottom plate 1. A plurality of pillars 11, the elastic member that is sleeved on the upper end of each pillar 11, the single-tube sheath 10 that is installed on the upper end of each pillar 11 and contacts the elastic member, is located on the movable plate 7 and is connected with the single-tube sheath 10 grooves 8 corresponding to each other, and a locking device is also provided between the other end of the movable plate 7 and the bottom plate 1 .

[0025] Preferably, the elastic component used in the present invention is a sprin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com