Automatic labeling mechanism with multi-station structure and for lithium battery automatic production

A lithium battery, multi-station technology, used in labeling machines, labels, packaging, etc., can solve problems such as large energy loss, inaccurate labeling positions, and loose labeling tapes, reducing energy consumption and achieving consistent height and position. , the effect of improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

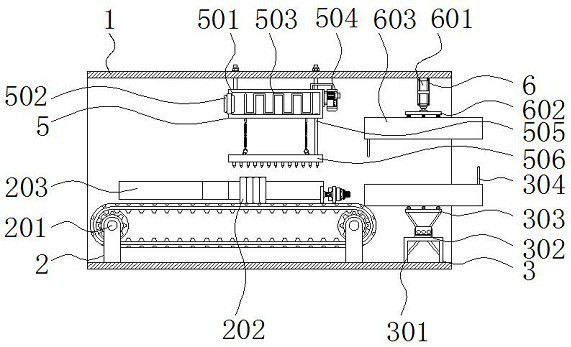

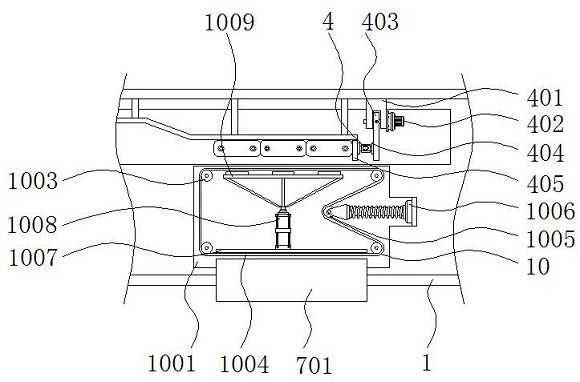

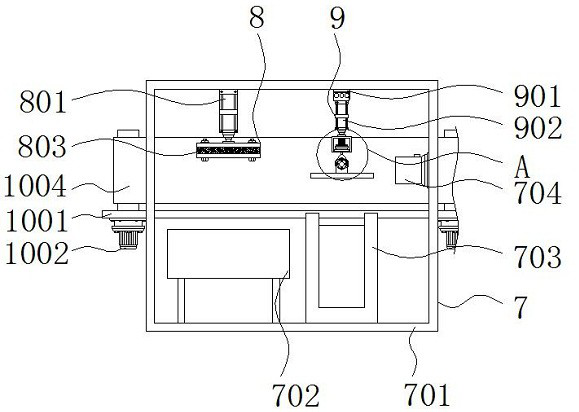

[0082] Such as figure 1 and Figure 5 As shown, an automatic labeling mechanism with a multi-station structure for automatic production of lithium batteries includes: a conveying mechanism 2 is provided on the inner lower wall of the equipment casing 1; the conveying mechanism 2 includes: a belt conveyor 201, a belt conveyor 201 is mainly used to transport the lithium battery body 202; the lithium battery body 202 is placed on the upper end of the belt conveyor 201; the fixed baffle 203 is arranged at the rear end of the lithium battery body 202, and the fixed baffle 203 is mainly The lithium battery body 202 has the effect of blocking and positioning; the collection mechanism 3 is arranged on the inner lower wall of the equipment casing 1, and the collection mechanism 3 is located on the right side of the conveying mechanism 2; the collection mechanism 3 includes: a pad 301, mainly The first electric slide rail 302 is supported and installed; the first electric slide rail 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com