Full-automatic pressing equipment

A fully automatic and equipment technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of high labor intensity, many people, low production efficiency, etc., and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

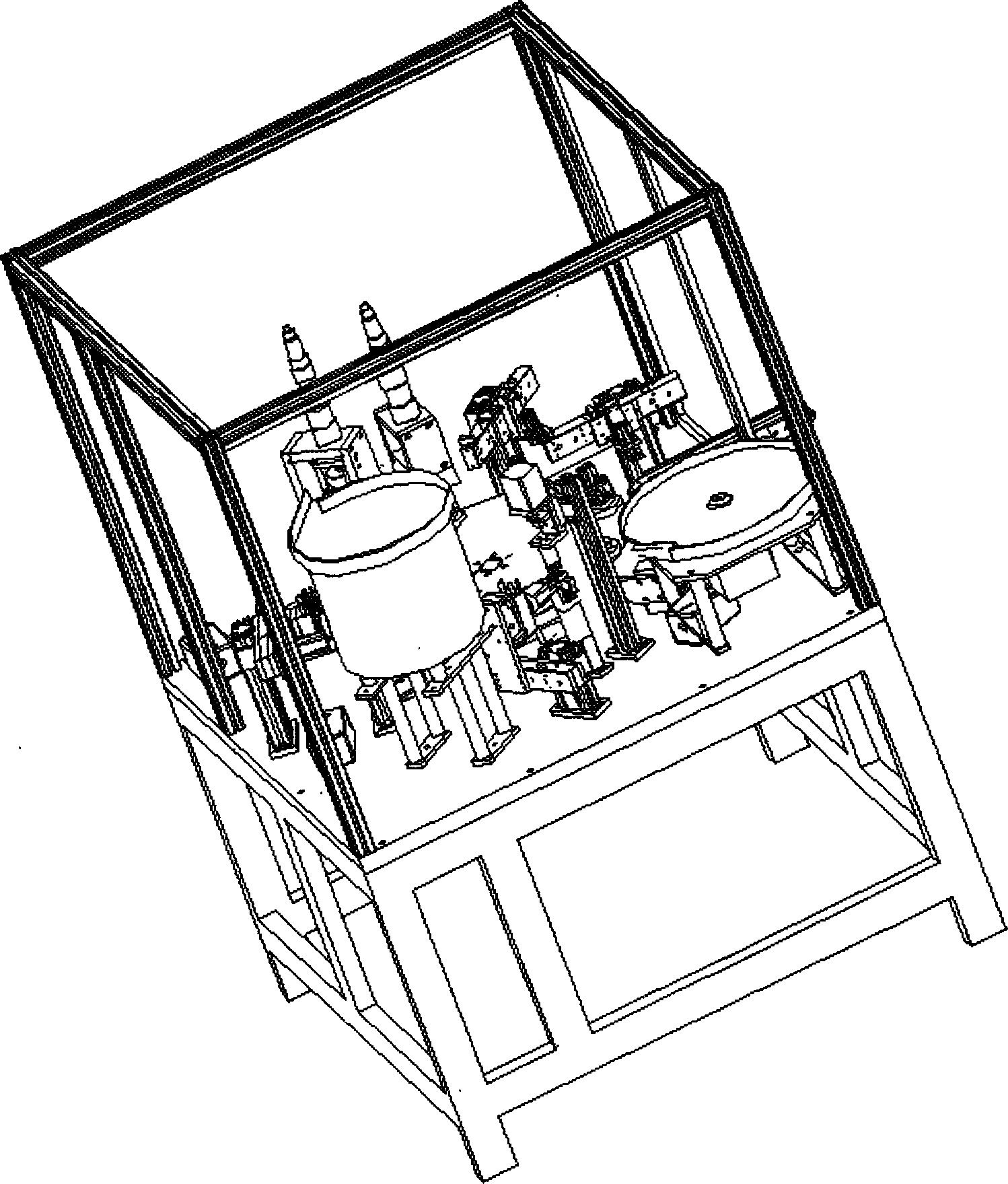

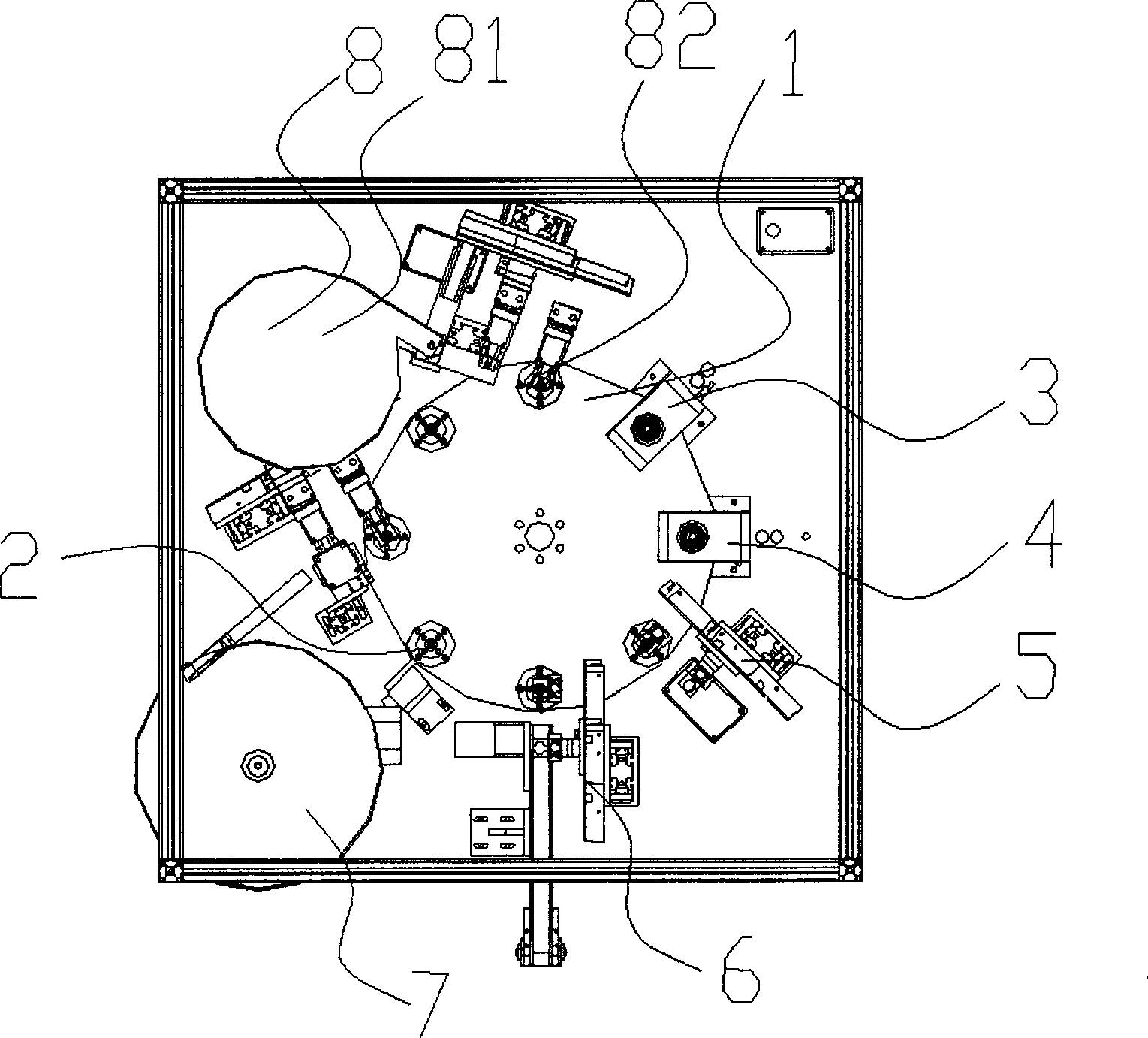

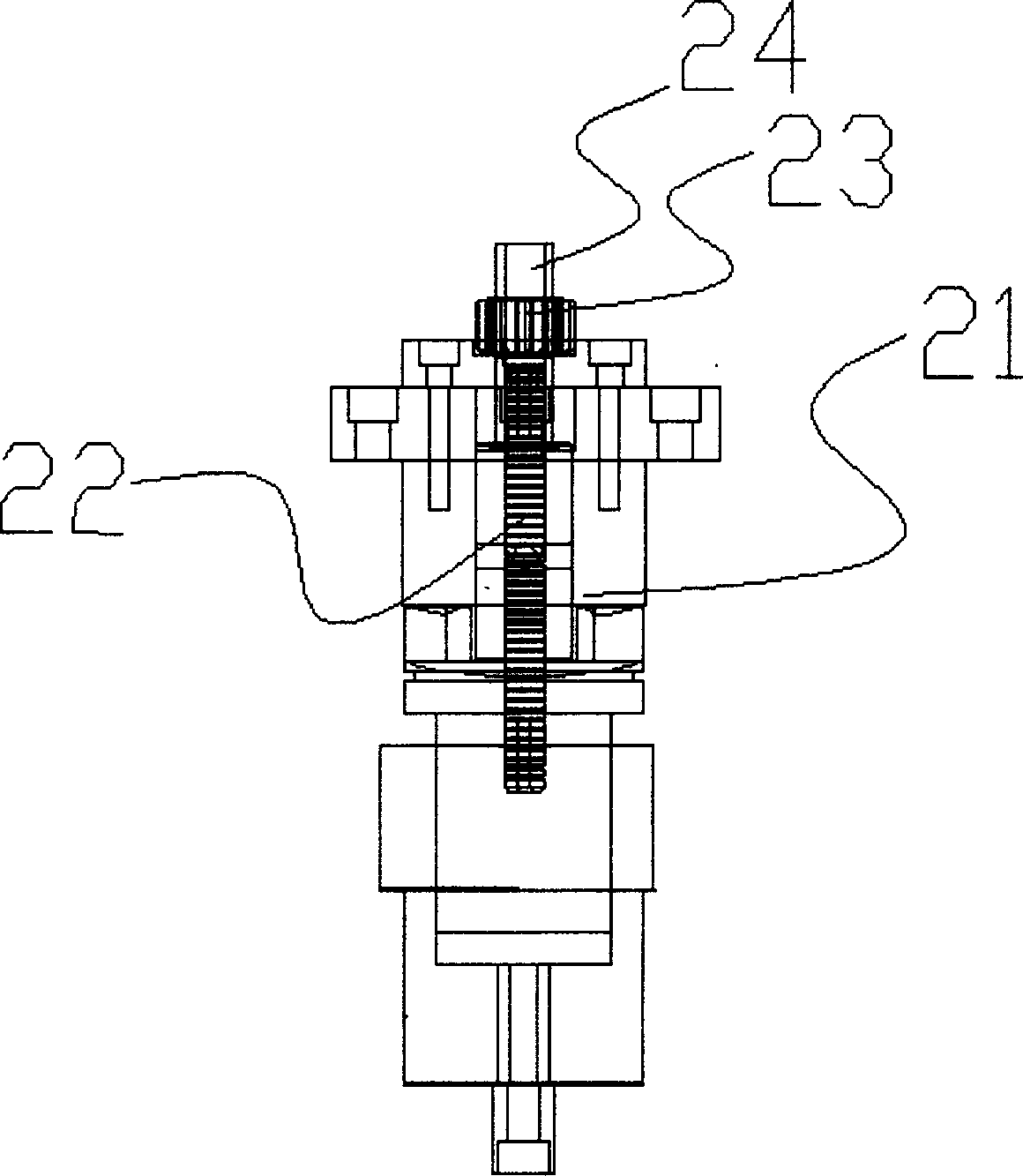

[0022] Such as figure 1 , 2 As shown, a fully automatic press-fitting device includes a turntable 1, and eight bases 2 are arranged at equal intervals on the turntable 1, and the eight bases correspond to the feeding equipment 7 of the mold 1, the feeding equipment 8 of the mold 2, the pressing Detection module 3, shaping detection module 4, unqualified product discharge manipulator 5, qualified product discharge manipulator 6, reset device, cleaning device, mold 1 feeding equipment 7 and mold 2 feeding equipment 9 all include feeding Turntable 81, this feeding turntable 81 is connected with manipulator 82, and base 2 comprises hollow cylinder 21, as image 3 As shown, the hollow body is provided with a cylinder 22 that can move up and down, and the press-in detection module 3 includes an oil cylinder 31, such as Figure 4 As shown, an oil cylinder connecting rod 32 is connected under the oil cylinder 31, a die connecting rod 33 is connected under the oil cylinder connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com