Apparatus for printing on a curved surface of an object through an ink jet print head

A technology of inkjet printing and printing head, which is applied in printing, transfer materials, power transmission devices, etc., can solve problems such as deviation and achieve the effect of reducing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

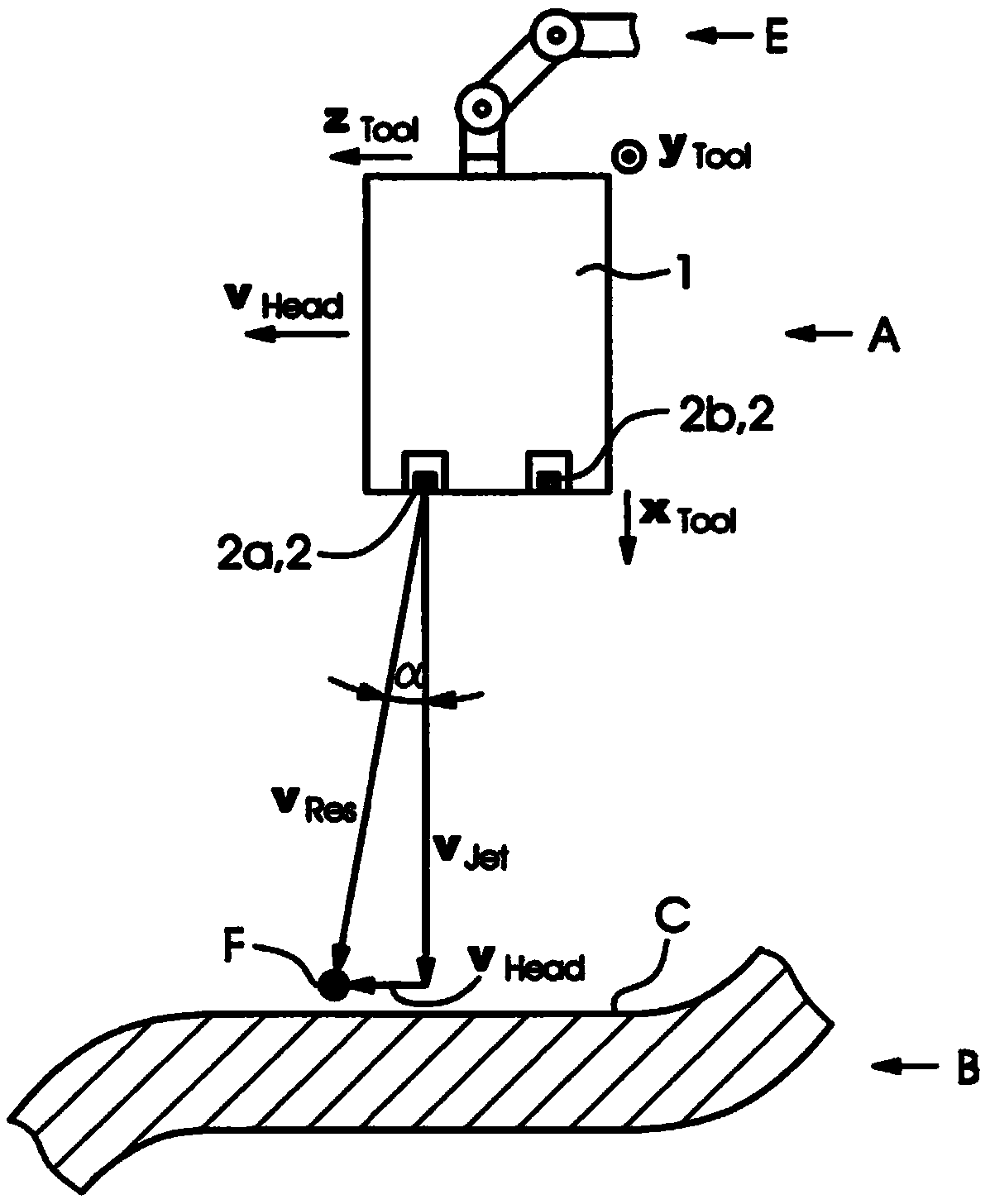

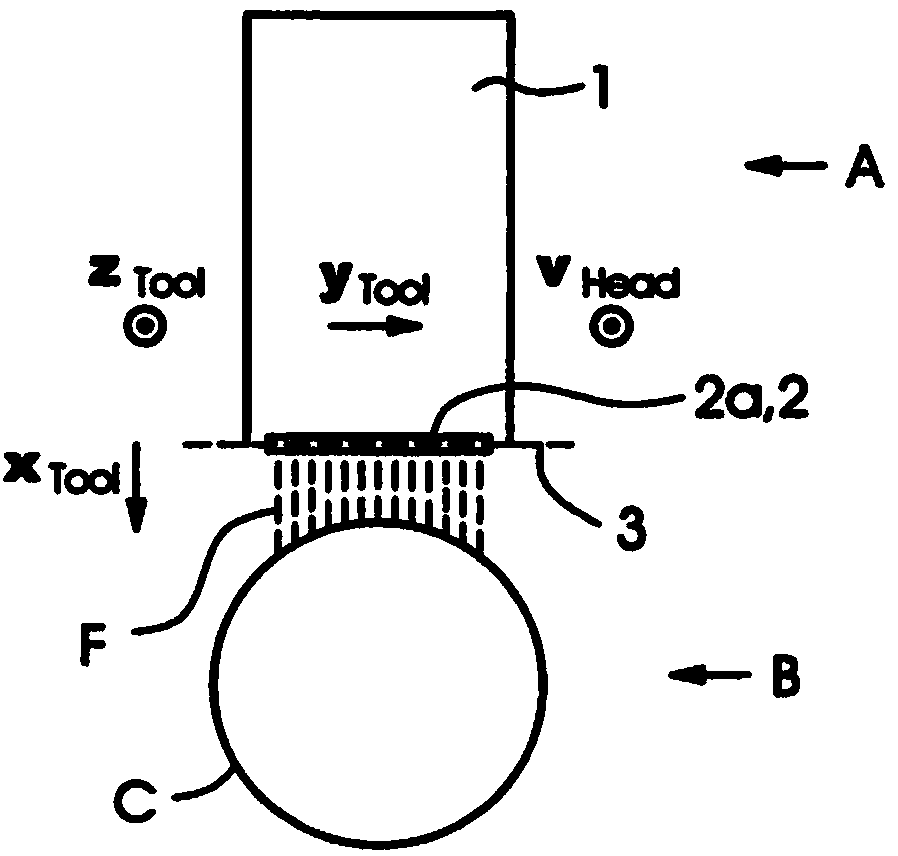

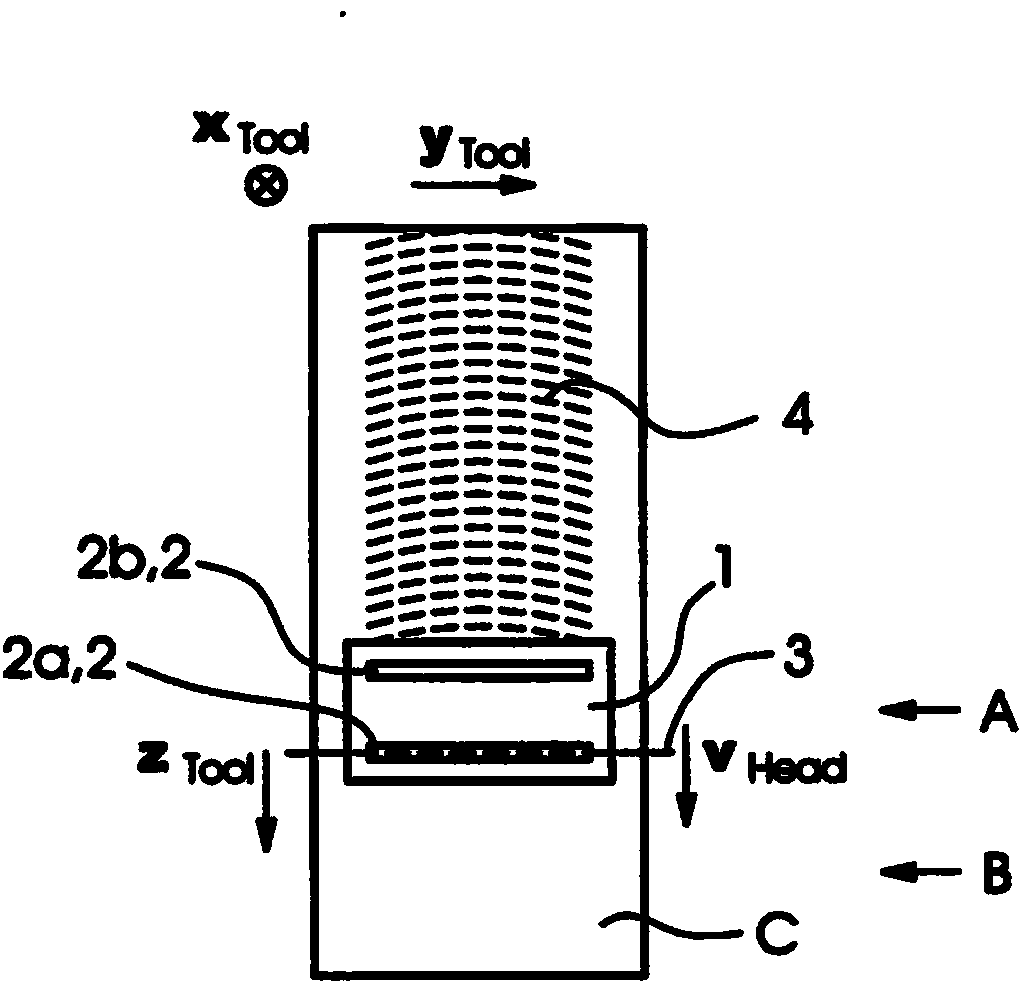

[0042] Figure 1A shows a side view of a device A with an inkjet print head 1 printing on a curved surface C of an object B, eg a tube. The print head has two nozzle rows 2a and 2b with corresponding inkjet nozzles 2 (better seen in FIG. 1B ). However, the printing head 1 can also have only one nozzle row or more than two nozzle rows.

[0043] The mutually orthogonal axes relative to the coordinate system fixed by the printing head (print head coordinate system) are indicated in the drawing by xTool, yTool and zTool. In a preferred embodiment, the inkjet print head A is moved by a robotic arm E for generating a relative velocity component between the print head A and the surface C. Here, the axes xTool, yTool and zTool can be understood as the axes of the tool coordinate system of the robotic arm E.

[0044] The speed and direction of movement (forward movement or main movement) of the printing head A during printing is indicated in the figure by the vector vHead. When print...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com