Windscreen wiper motor

A windshield wiper and motor technology, which is applied in vehicle cleaning, mechanical energy control, vehicle maintenance, etc., can solve the problems of cost and high manufacturing cost, and achieve the effect of stable installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] Identical elements or elements with the same function are identified by the same reference numerals in the figures.

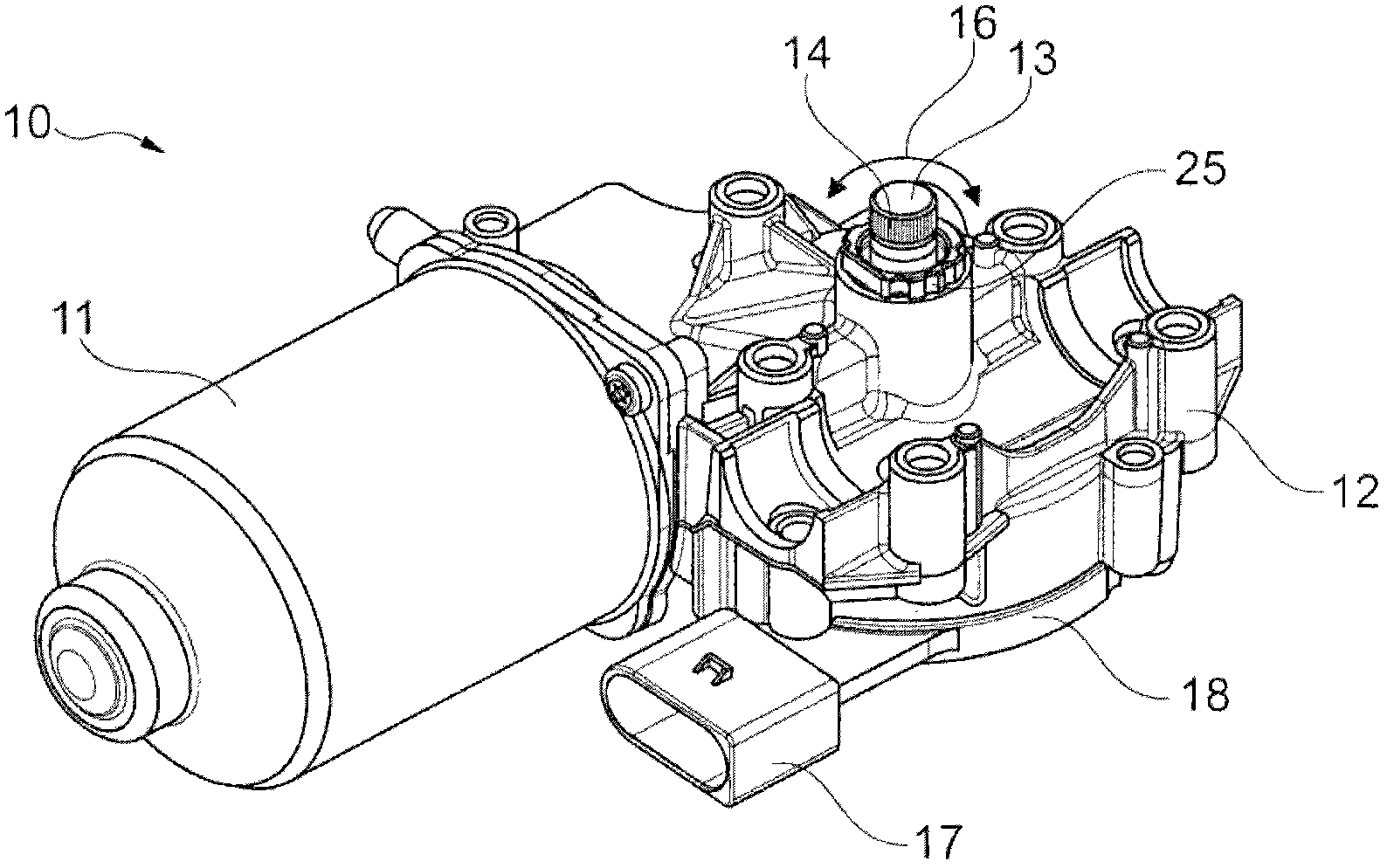

[0073] figure 1 and 2 A windscreen wiper motor 10 according to the invention is shown, for example for use inter alia in the actuation of a wiper linkage (not shown). The windscreen wiper motor 10 comprises a drive motor 11 which is in the form of an electric motor and which can be flange-mounted on a housing 12 of the windscreen wiper motor 10 for accommodating a transmission (not shown in detail). The transmission serves to reduce the rotational speed of the drive motor 11 while increasing its torque.

[0074] Out of the top side of the housing 12 protrudes the upper end of the shaft 13 on the outer circumference of which splines 14 are formed. By means of the spline 14, the rod 23 (only in the image 3 shown in ) is rotationally mounted on the shaft 13 so that when the shaft 13 rotates in the direction of the double arrow 16, the rod 23 moves conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com