Ship heel balance automatic control system and method

An automatic control system and heeling technology, applied in the field of ships, can solve the problems of low anti-rolling effect of anti-rolling tanks, low economic risk and environmental conditions, and inability to perform anti-rolling, so as to improve navigation performance, reduce burden, and enhance safety sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

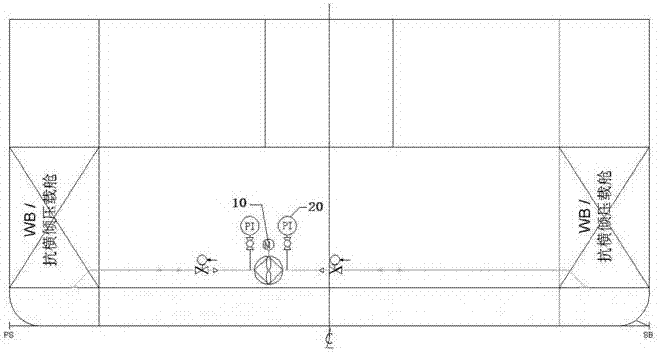

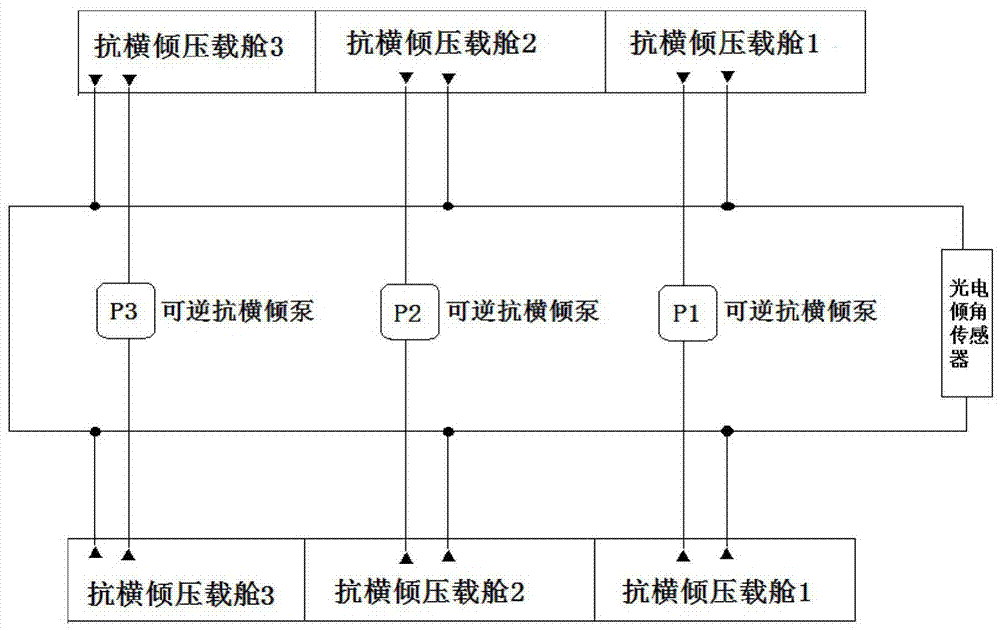

[0024] In the first specific embodiment of the present invention, a ship comprehensive balancing system is provided, which is combined with a fin stabilizer, a water stabilizer tank and an anti-heeling balance tank, so as to balance the ship to the greatest extent.

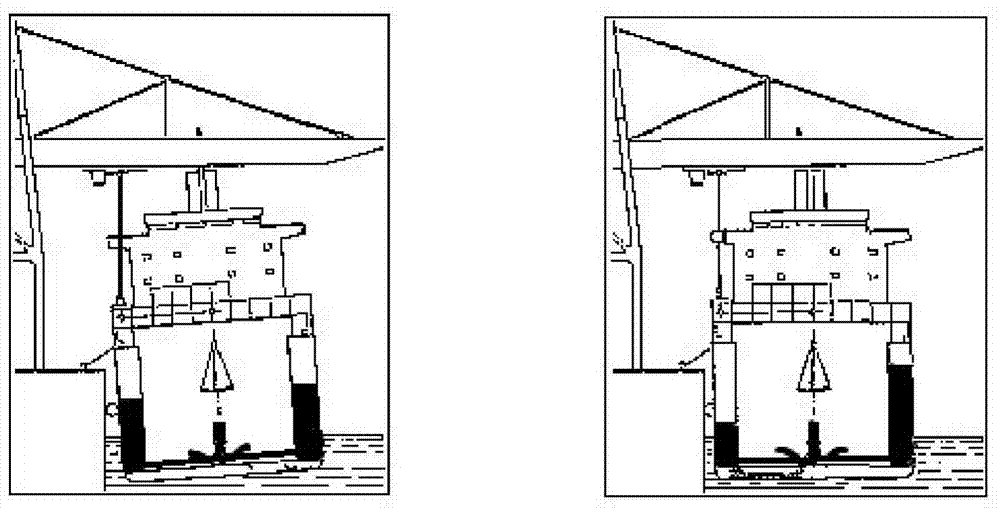

[0025] The fins of the stabilizer protrude from the two chords of the hull and are installed at a certain depth below the waterline. Its shape is similar to that of a rudder. A pair of fin stabilizers shall be arranged on the same widest cross-section of the ship, so that the center line of the fin shaft of the stabilizer intersects the ship's roll axis. When the ship sails in wind and waves and produces rolling motion, the fins are controlled by the fin stabilizer control system and rotate correspondingly according to the law of sea disturbance. After the ship is equipped with fin stabilizers, the controller can act on the fin stabilizers to change The ship's natural frequency and roll damping, thereby changing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com