Anti-capsizing mechanism for transfer loading and unloading transport ship and transport ship with the same mechanism

A transport ship and anti-overturning technology, applied in transportation and packaging, cargo handling equipment, ship accessories, etc., can solve problems affecting operation, navigation stability, unbalanced force, poor anti-overturning performance, etc. Through performance, balanced gravity distribution, flexible storage and transportation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

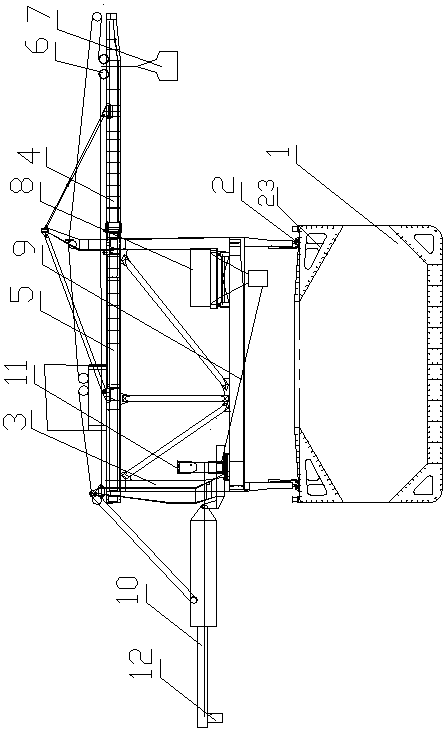

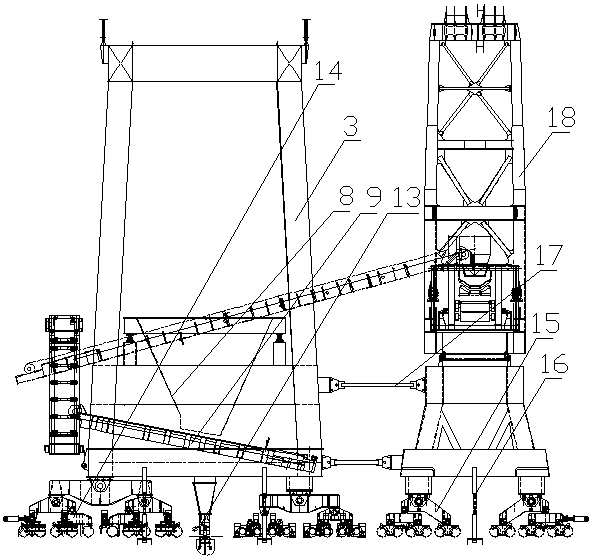

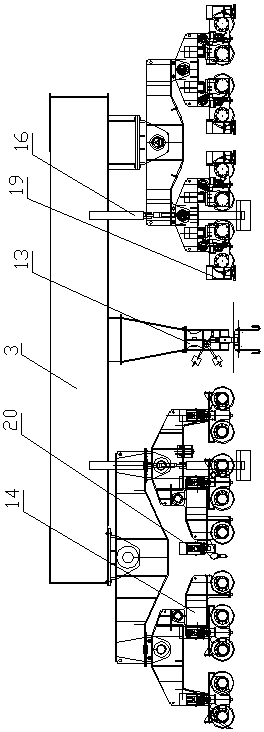

[0040] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0041] Such as Figure 1 to Figure 10 The transport ship shown has a hull 1; two parallel rails 2 arranged on the deck of the hull 1; a traveling mechanism that can move on the rails; a gantry 3 connected to the traveling mechanism; a discharge device connected to the gantry 3 , a feeding device and a loading device; the unloading device includes a first arm frame 4 whose first end is hinged to the first end of the top beam 5, and a mobile trolley 6 that can walk on the door frame top beam 5 and the first arm frame 4 , the retrieving hopper 7 connected with the mobile trolley 6; the feeding device includes a feeding hopper 8 connected with the door frame 3, and a first feeding mechanism 9 for receiving the discharge of the feeding hopper 8; the feeding device includes a first end and a door The second arm frame 10 hinge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com