Cloth guide roller with racks

A cloth guide roller and rack technology, which is applied in the direction of processing textile material drums and textile material carriers, etc., can solve the problems of cloth surface fluff damage, easy slipping, etc., achieve small damage to the cloth surface, improve grip, reduce The effect of relative sliding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below by specific embodiment, in conjunction with accompanying drawing, the technical scheme of the present invention is described in further detail:

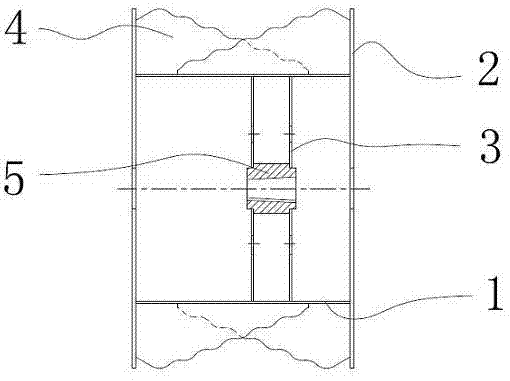

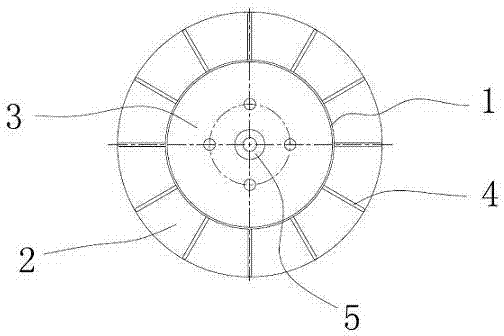

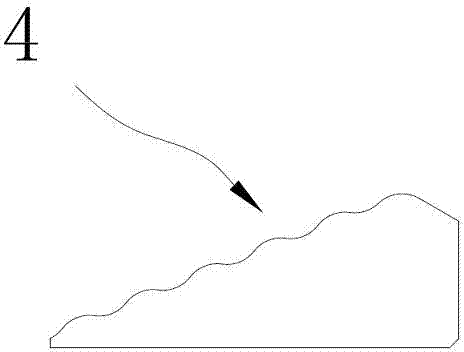

[0019] as attached figure 1 , attached figure 2 , and attached image 3 As shown, the cloth guide roller with a rack includes a roller 1, the cross section of the roller 1 is a ring shape, and the surface of the roller 1 is provided with multiple rows of racks 4, and the racks 4 are evenly welded to the On the surface of the roller 1, the rack 4 is parallel to the axis of the roller 1. The roller cover 2 is provided at both ends of the roller 1. The cross section of the roller cover 2 is circular. The end face is welded and fixed, and the middle part of the roller cover 2 is provided with an axis hole that allows the external rotating shaft to pass through. The roller 1 is provided with a connecting plate 3, and there are two connecting plates 3, the two connecting plates 3 are parallel to each other, the axis of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com