Double-layer flannelette splitting device

A flannel, double-layer technology, applied in the field of double-layer flannelette splitting device, to achieve the effects of improving work efficiency, convenient use, and shortening production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

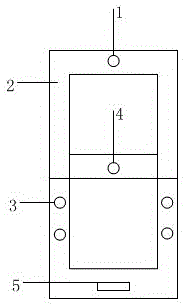

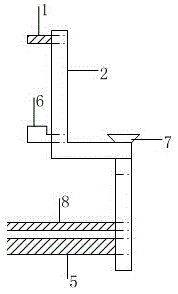

[0010] like figure 1 As shown, this double-layer all flannelette dividing device comprises 2 cast iron side walls 2, strut 1, connecting cross bar 5, 2 packing rollers 8, triangular blade 6; A longitudinal section of described cast iron side wall 2 is "Sun" shape; the support rod 1 is fixed at the center of the upper end of the "sun"-shaped structure of the cast iron side wall; the lower parts of both sides of the cast iron side wall have several heights and are axially symmetrical along the vertical center line of the cast iron side wall 2 The hole 3 is used to install two packing rollers; the center of the transverse structure of the waist of the cast iron side wall 2 also has a hole 4 for installing the triangular blade 6; the connecting cross bar 5 is located at the center of the lower part of the cast iron side wall for connecting two cast iron side walls;

[0011] Specifically, the cast iron side wall 2 is divided into upper and lower parts, wherein a longitudinal secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com