Heating roller

A technology for heating drums and cylinders, applied in roads, road repairs, roads, etc., can solve problems such as polluting the environment, damaging the health of people around the operator, and the asphalt cannot be fully mixed and evenly heated, so as to reduce pollution and ensure good health , to ensure the effect of heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] An implementation manner of the present invention will be briefly described below in conjunction with the accompanying drawings.

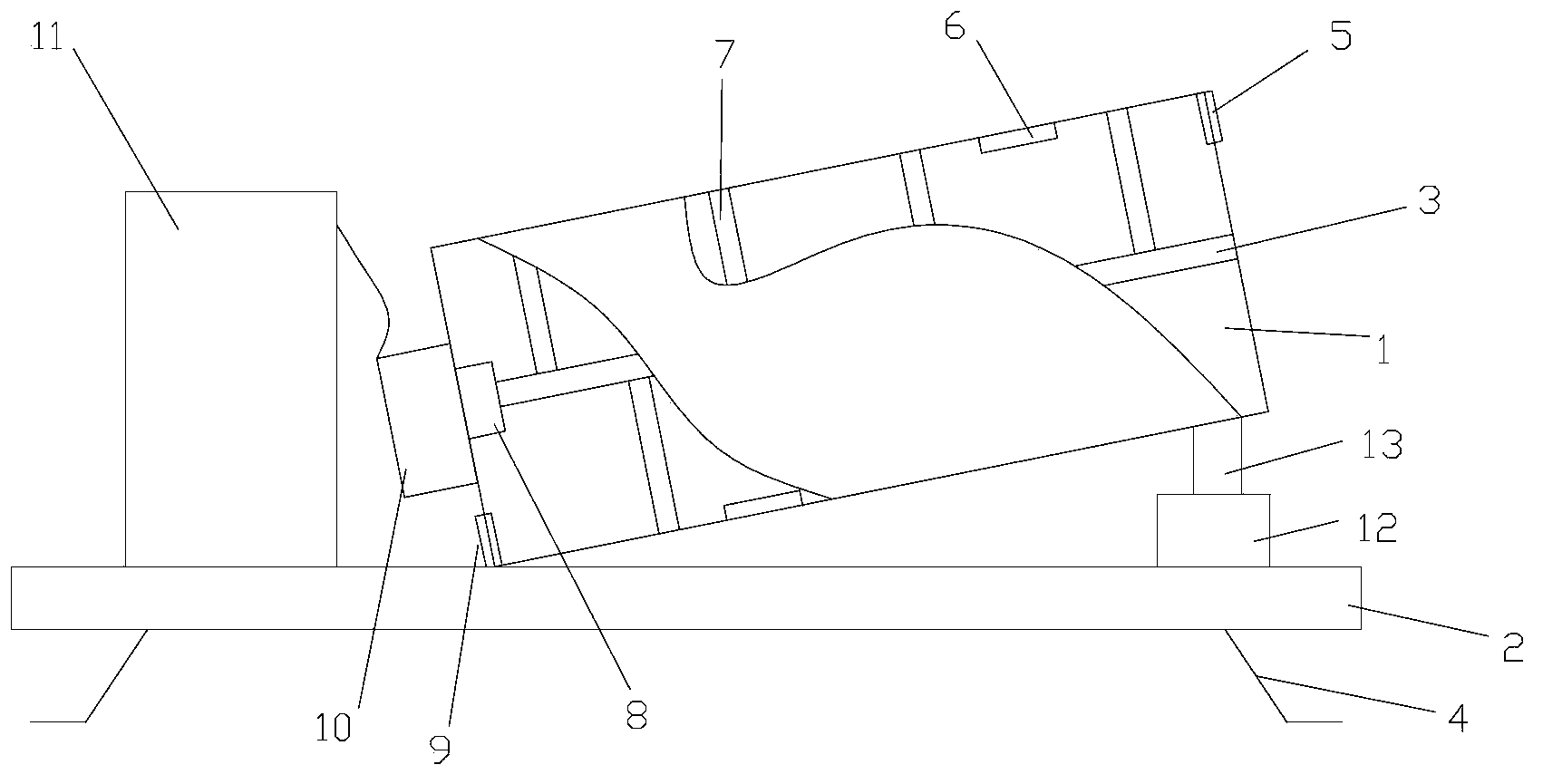

[0024] Such as figure 1 As shown, a heating roller includes a cylinder body 1 provided with a material inlet 5 and a material outlet 9; it is characterized in that it also includes a supporting mechanism, a rotating mechanism, a lifting mechanism and a sensing mechanism. The support mechanism includes a support base 2 and a support foot 4 , the support foot 4 is fixedly connected to the bottom end of the support base 2 , and one end of the cylinder body 1 is movably connected to the support base 2 . The rotating mechanism includes a motor 10 , a transmission shaft 8 and a rotating shaft 3 ; The lifting mechanism includes a hydraulic cylinder 12 and a lifting arm 13 , and the lifting arm 13 is movably connected with the hydraulic cylinder 12 . The sensing mechanism includes a temperature sensor 6 and a controller 11 , the temperature sensor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com