Pressure storage type efficient and energy-saving excavator

A high-efficiency, energy-saving, excavator technology, applied in the direction of earth mover/shovel, construction, etc., can solve the problems of unfavorable excavator energy-saving engineering cost reduction, increase excavator oil consumption, unstable output power and other problems, and achieve optimization work. The effect of load, simple structure and continuous and stable pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] In order to more fully explain the implementation of the present invention, implementation examples of the present invention are provided. These implementation examples are only illustrations of the device and do not limit the scope of the present invention.

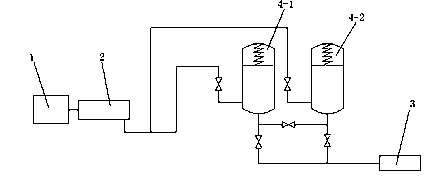

[0008] as attached figure 1 As shown, a pressure storage type high-efficiency energy-saving excavator includes an engine 1 and a hydraulic pump 2. The excavator is provided with a hydraulic pressure accumulator, and the engine 1 drives the hydraulic pump 2 to be hydraulically stored in the hydraulic pressure accumulator through the pipeline. The hydraulic pressure accumulator drives the hydraulic actuator through the pipeline. There are at least two hydraulic pressure accumulators. The hydraulic actuator includes a hydraulic cylinder and a hydraulic motor. 3 shows a hydraulic cylinder. The hydraulic pressure accumulator A pressure sensor is arranged in the pressure accumulator, and the pressure sensor transmits t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com