Template

A formwork and board body technology, which is applied in the field of formwork/formwork components, joints of formwork/formwork/working frames, and on-site preparation of building components, which can solve the problems of unpopularity, large size, equipment and mold opening costs High cost and other issues to achieve the effect of saving materials and costs, improving service life, improving rigidity and support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

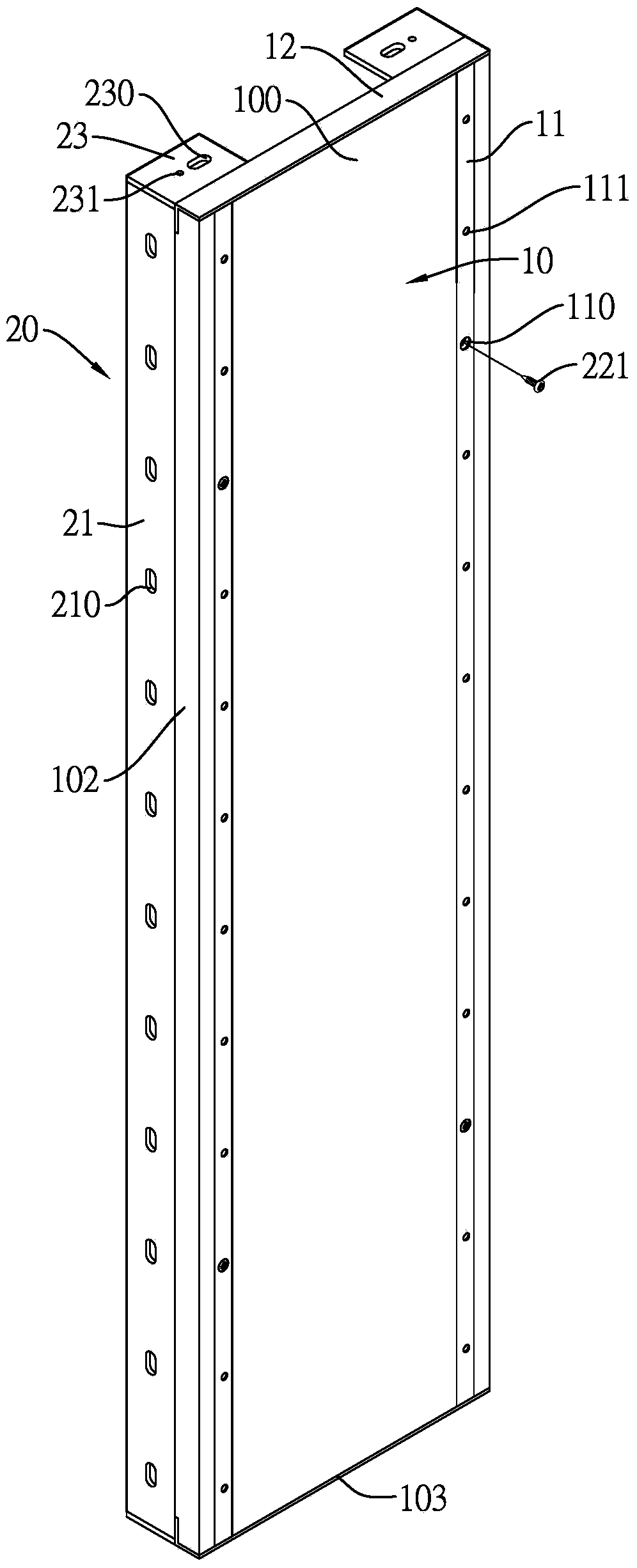

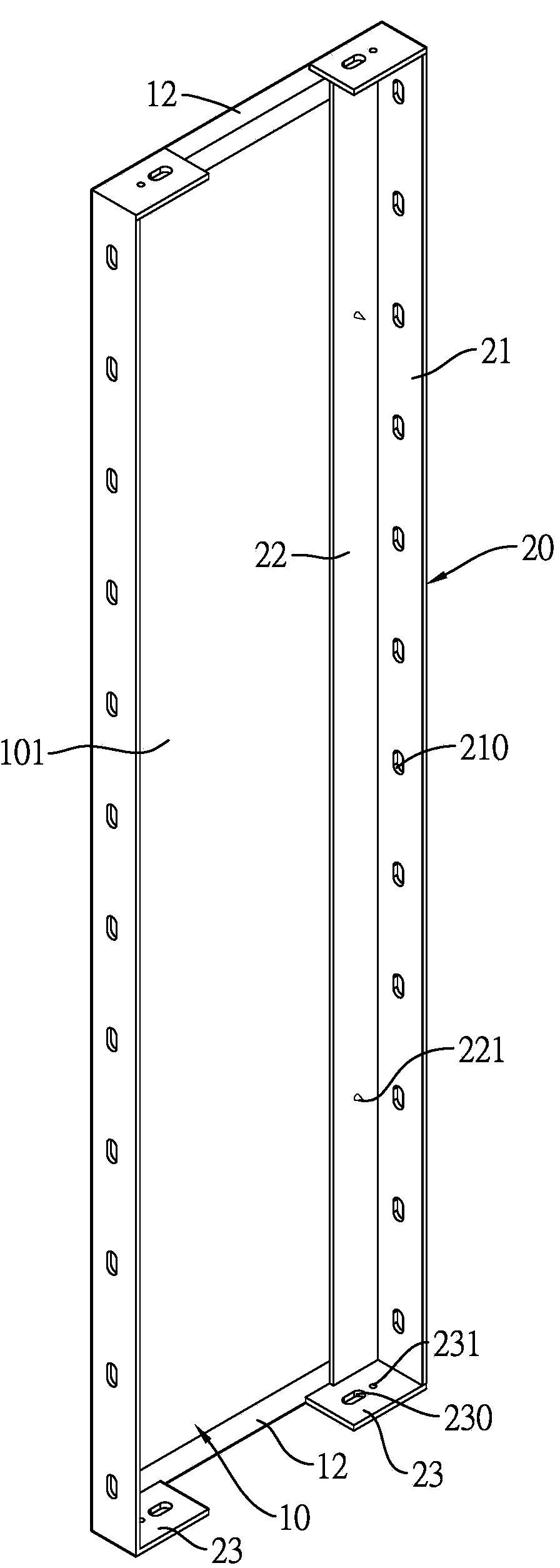

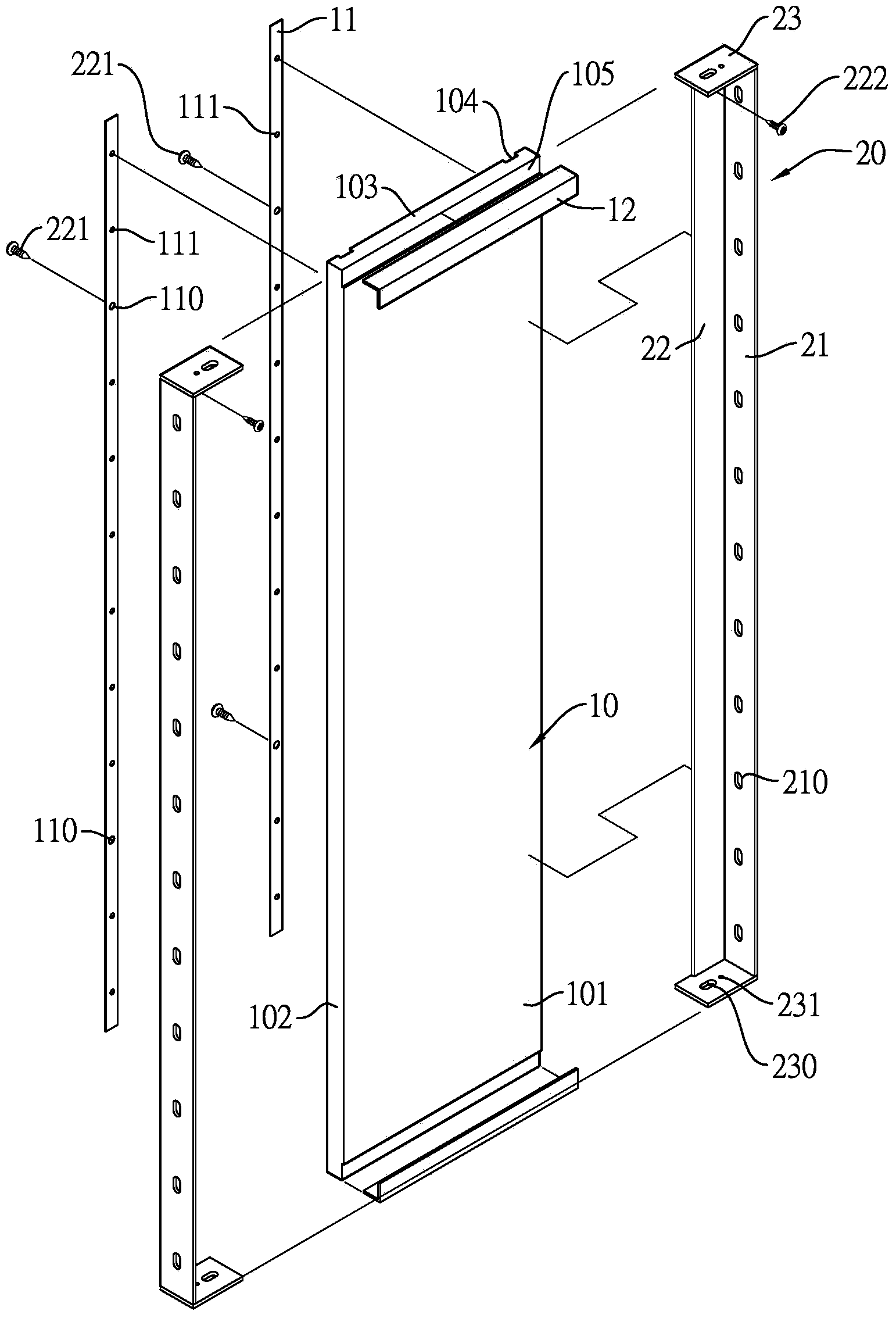

[0047] This invention is a template, see Figure 1 to Figure 3 As shown, it includes a plate body 10 and two angle steel columns 20 .

[0048] The board body 10 is a wooden board body. The board body 10 has a certain thickness and is in the shape of a long rectangle. The board body 10 has a front side 100 and a back side 101. Short side 103.

[0049] In a specific embodiment of the present invention, on both sides of the front side 100 of the board body 10, a slot 104 is respectively extended and recessed along the direction of the two long sides 102, and a metal bead 11 is embedded in the two slots 104. , the metal bead 11 is an elongated metal sheet, and the sheet of the metal bead 11 is provided with a plurality of bolting holes 110 and fixing holes 111 at intervals along the long axis. The two ends of the reverse side 101 of the plate body 10 are respectively recessed with a side groove 105 along the two short sides 103, and a corner protection strip 12 is respectively p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com