Tool type concrete door and window formwork support

A technology for concrete and mouth formwork, which is applied in the fields of formwork/formwork/work frame, on-site preparation of building components, construction, etc., can solve the problems of poor reinforcement reliability, low turnover rate of supporting materials, and long labor hours, and eliminates the need for The effect of mold expansion or edge leakage, eliminating randomness and high turnover rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

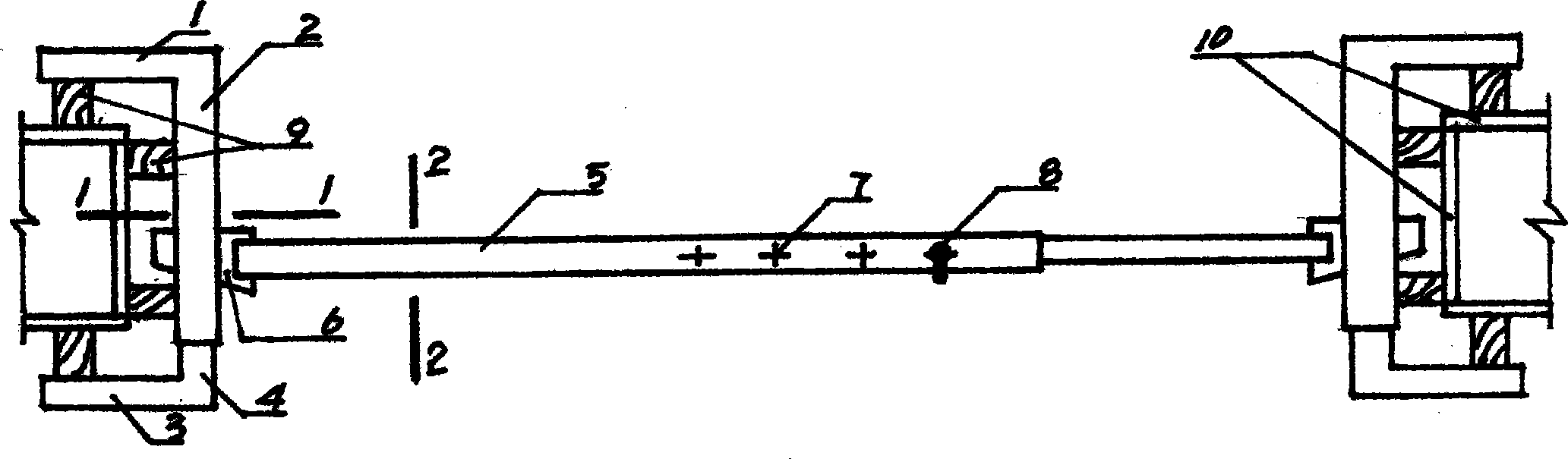

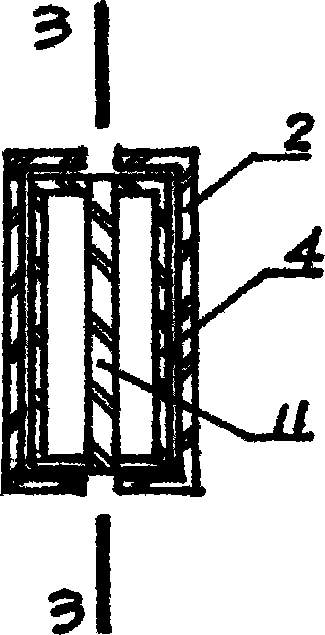

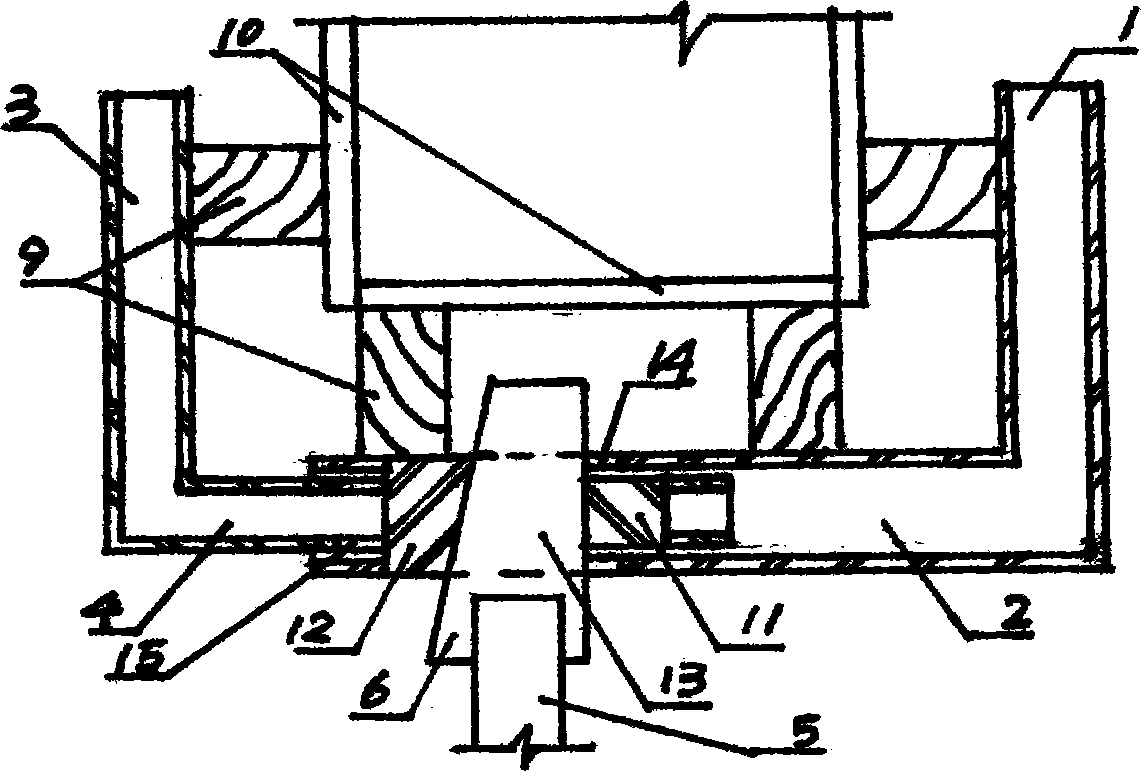

[0015] When supporting the formwork, insert the direct pin 8 into the adjustment hole 7 at the selected adjustment position according to the size of the door window, and insert the wedge plate 6 into the enclosing space 13 of the two-way supporting mouth groove of the mouth and jaw bed at both ends, and simultaneously the left and right jaws at the two ends are forked into two respectively. The template back flute 9 of the side door window is knocked down on the two-way support opening at the higher end, right jaw bed 2 to the right jaw arm 1, left jaw arm 3, and right jaw bed 2 and the template back flute 9 are clamped to complete Formwork support; when removing the formwork, reversely knock the right jaw bed 2 to loosen it, and then remove all parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com