Eight-section heating drying tunnel

A drying tunnel and heating tube technology, applied in heating devices, lighting and heating equipment, drying and other directions, can solve the problems of low production efficiency, poor heating and ventilation effect, etc., and achieve the effects of improving production efficiency, using safety, and shortening time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

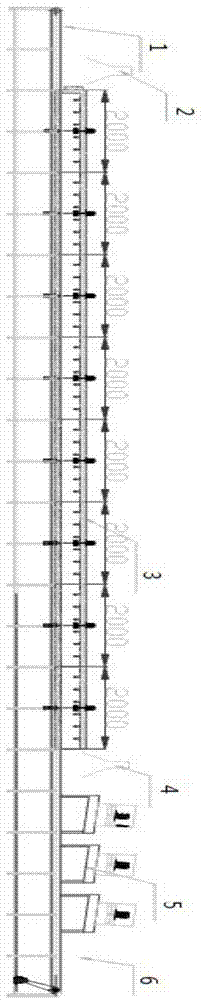

[0025] refer to figure 1 , is a kind of 8-section heating drying tunnel, comprising: a drying zone (3), consisting of 8 sections of furnace chambers, an upper piece zone (1) and a lower piece zone (6) at both ends of the drying zone, and the upper piece zone (6) A smoke outlet (2) is provided on the part area, a smoke outlet (4) and a cooling section (5) are provided on the lower part area;

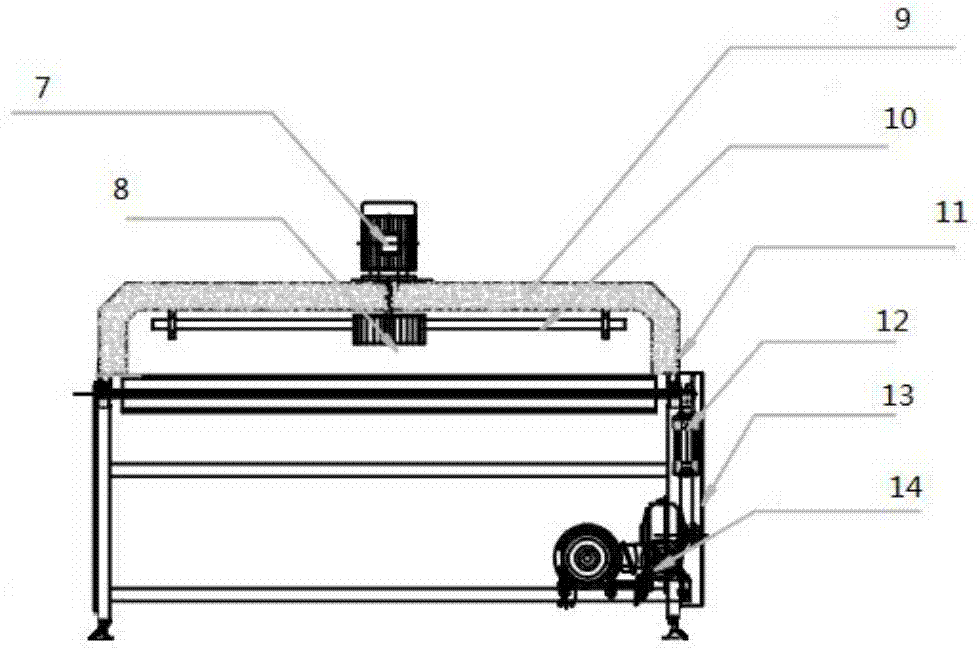

[0026] The furnace chamber of each section comprises: a heating pipe (10), an insulating layer (9) above the heating pipe, an axial flow fan (7), a fan blade (8) below the heating pipe, and a fan blade (8) positioned below the fan blade. Guide rail (11), located on one side of the furnace cavity, below the guide rail is successively a jacking cylinder (12), a sealing plate (13) and a dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com