Steel rail flaw-detection method based on laser ultrasonic and high-speed photography image fusion

A laser ultrasound, high-speed camera technology, used in the analysis of solids using sonic/ultrasonic/infrasonic waves, optical testing of flaws/defects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

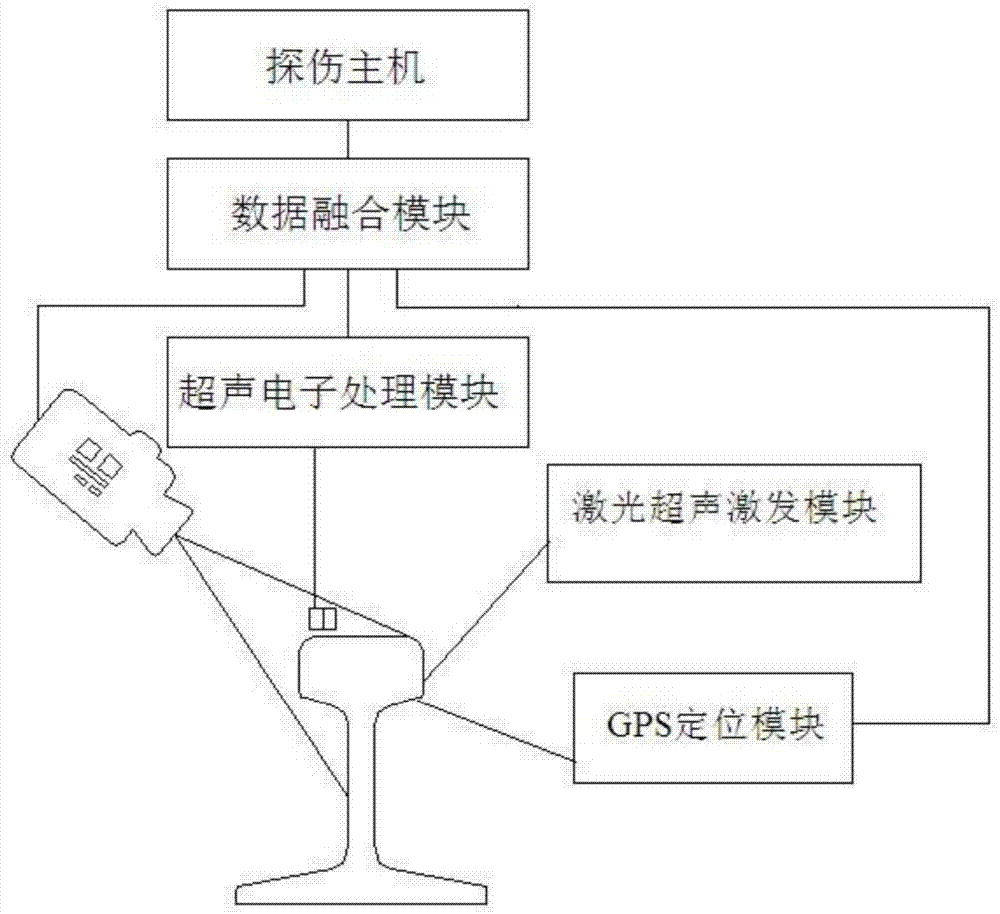

[0030] Such as figure 1 As shown, the present invention provides a rail flaw detection method for image fusion of laser ultrasound and high-speed imaging, comprising the following steps:

[0031] Step 1. Install a laser ultrasonic excitation module and a high-speed camera module on the rail flaw detection car. When the energy of the laser is focused and irradiated on the surface of the elastic material, part of it will be transferred to the material itself and manifested in the form of thermal energy and stress wave energy. By changing The geometry of the excitation laser can control the distribution of energy in the material and its impact on the material. Laser ultrasound is to use the instantaneous thermal interaction between high-energy laser pulses and the surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com