End face processor adjusting structure

A technology of adjusting structure and processor, applied in the direction of coupling of optical waveguides, etc., can solve the problems of increasing the diameter of the fiber end face, time-consuming and laborious, affecting the optical performance of the connector, etc., to achieve the effect of convenient installation and accurate alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing, the present invention is described in further detail:

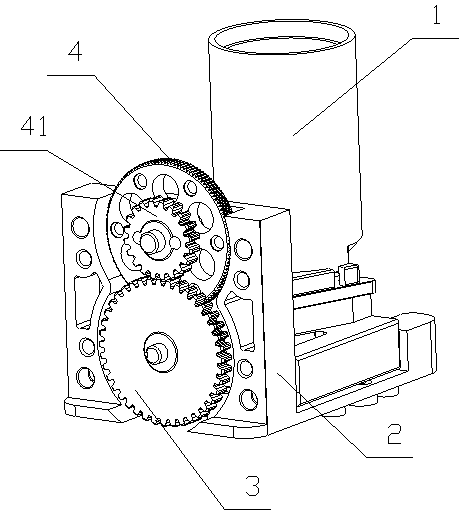

[0024] As shown in the figure: the adjustment structure of the end surface treatment machine includes a magnifying glass seat 1, a sliding table seat 2, and a sliding table; the magnifying glass seat 1 is arranged on the sliding table, and the sliding table is arranged on the sliding table seat 2; Swipe up.

[0025] The slide base 2 is L-shaped, and the vertical end surface of the slide base 2 has a transmission gear 3 and a rotary pulley 4; the rotary pulley 4 is provided with a coaxial small transmission tooth 41; . The axle center of transmission gear 3 is provided with screw rod, and screw rod links to each other with slide table.

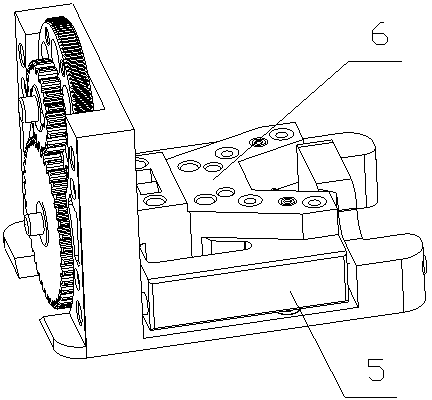

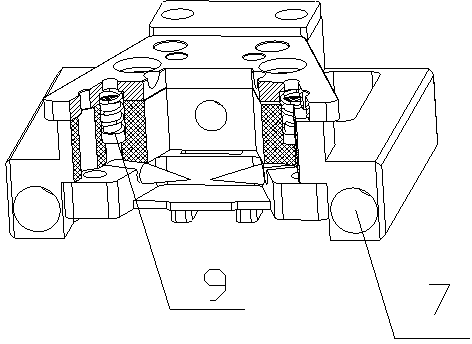

[0026] The slide table includes: a bottom slide table 5, a connecting slide table 6, and a needle cover 8; the needle cover 8 is arranged inside the bottom slide table 5; the top end of the bottom slide table 5 is provided with a con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com