Method of forming contacts on slide type switch

A contact, sliding type technology, applied in electrical switches, electrical components, contact surface shape/structure, etc., can solve problems such as insufficient contact surface pressure, contact tilting, and deterioration of operating unit position detection accuracy, and achieve improved position. The effect of detection accuracy and reliable contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Hereinafter, embodiments of the present invention will be specifically described with reference to the drawings.

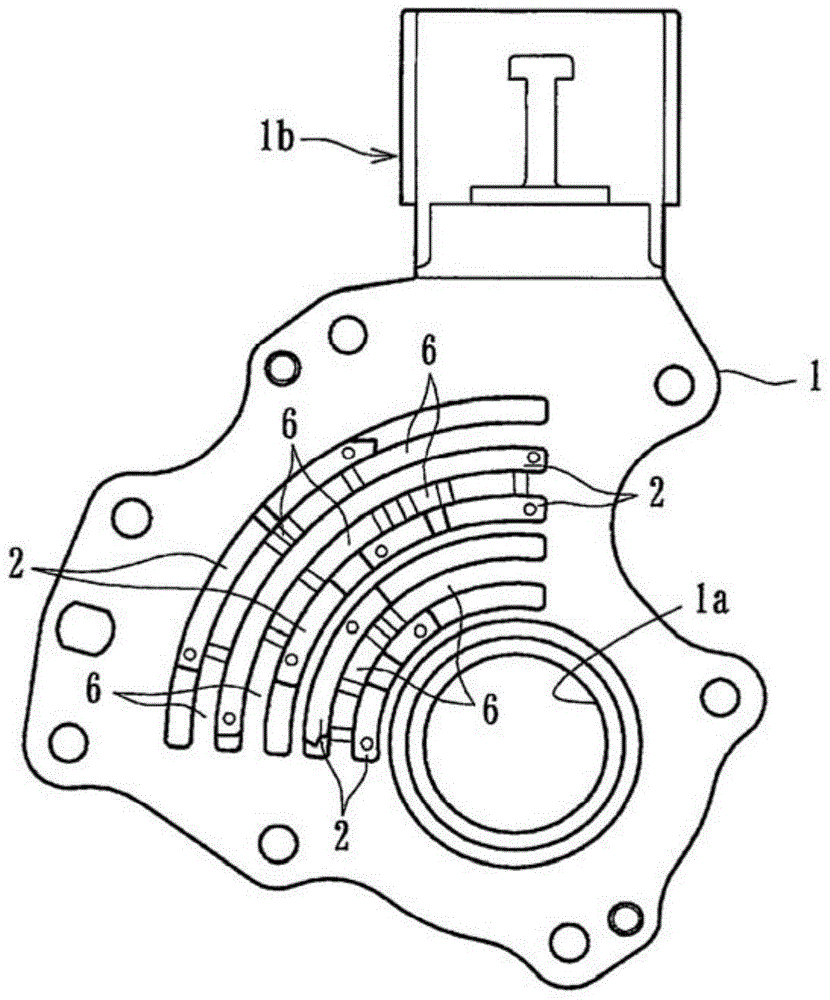

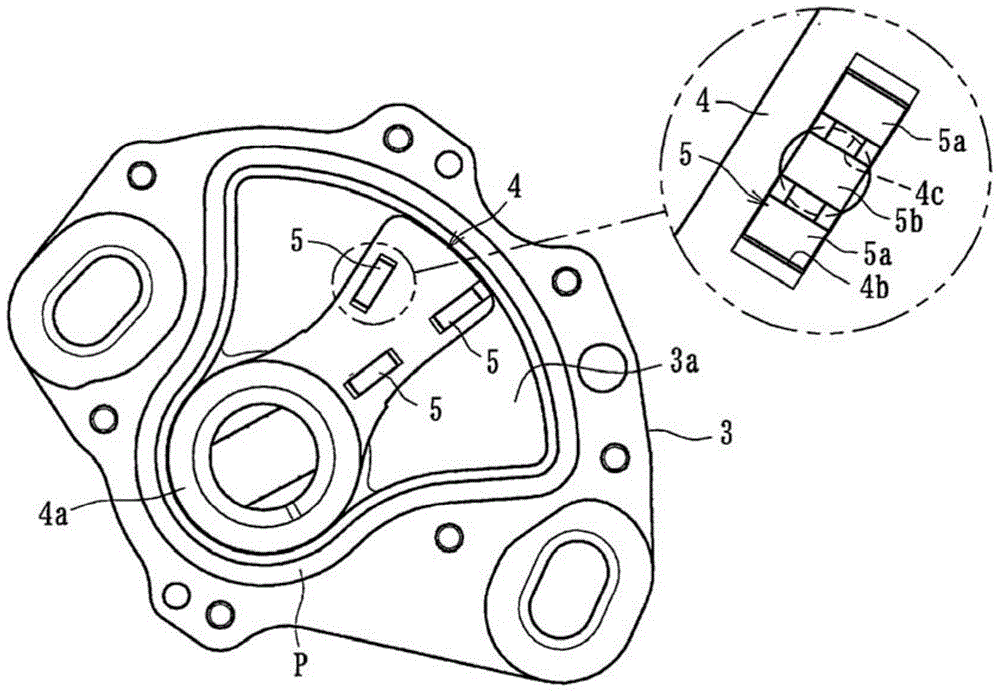

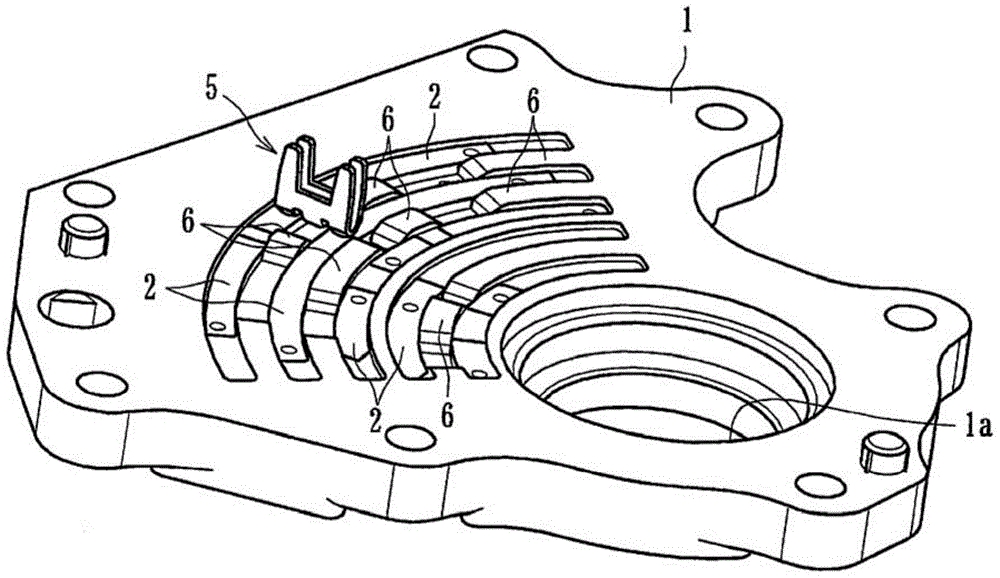

[0042] The slide type switch involved in this embodiment is suitable for a control switch for an automatic transmission, which is installed on an automobile and can detect the position of the shift lever of the automatic transmission, such as figure 1 , 2 As shown, a main body member 3 to which a movable member 4 is attached is assembled to a terminal block 1 on which a plurality of terminal strips 2 are formed to form a frame, and contacts 5 are formed on the movable member 4 .

[0043] The terminal block 1 is formed by molding a predetermined resin material into a predetermined shape, and a plurality of terminal plates 2 made of conductive members such as metal plates are insert-molded at predetermined positions. These terminal plates 2 extend in an arcuate shape along the rotation direction of the movable member 4 , are separated from each other at pred...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap