PMOLED (passive matrix organic light emitting diode) array substrate as well as manufacturing method, display device and mask plate thereof

A technology of array substrates and mask plates, which is applied in photolithographic process exposure devices, semiconductor/solid-state device manufacturing, microlithography exposure equipment, etc., can solve the problems of large number of mask plates and high production costs, and achieve simplified manufacturing processes and production The effect of cost reduction and production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

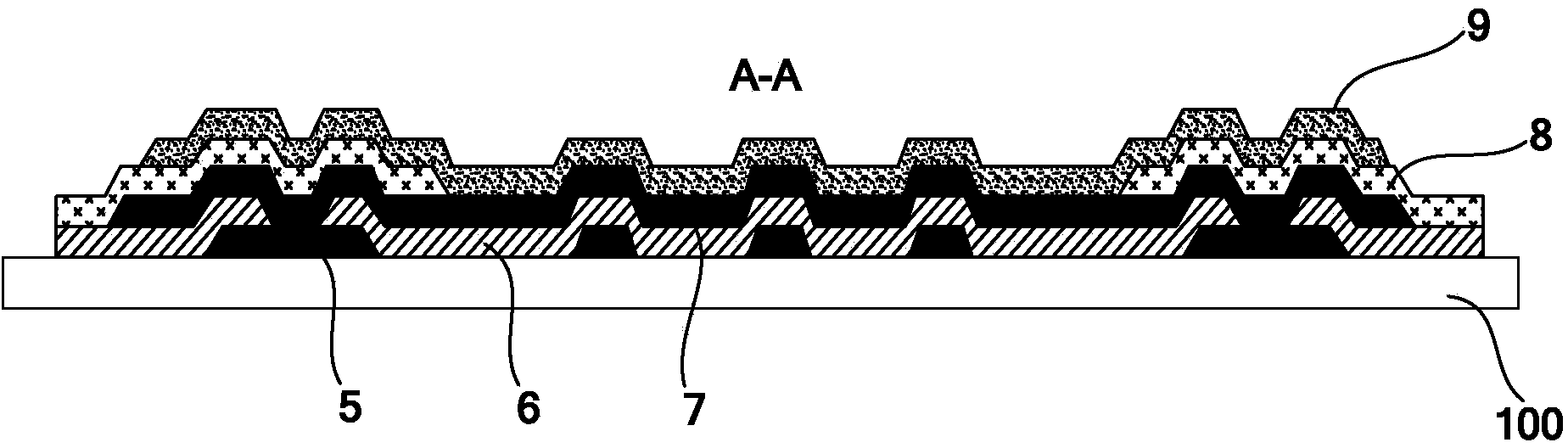

[0053] In order to reduce the number of masks used and reduce production costs, embodiments of the present invention provide a passive matrix OLED array substrate, a manufacturing method thereof, a display device, and a mask. In the technical solution of the present invention, the transparent conductive layer is located on the second metal layer, no insulating layer is provided between the transparent conductive layer and the second metal layer, and the transparent conductive layer and the second metal layer can be formed by using the same mask, Compared with the prior art, the number of masks used is reduced, the production cost is greatly reduced, and the manufacturing process is simplified.

[0054]In order to make the purpose, technical solution and advantages of the present invention clearer, the following examples are given to further describe the present invention in detail.

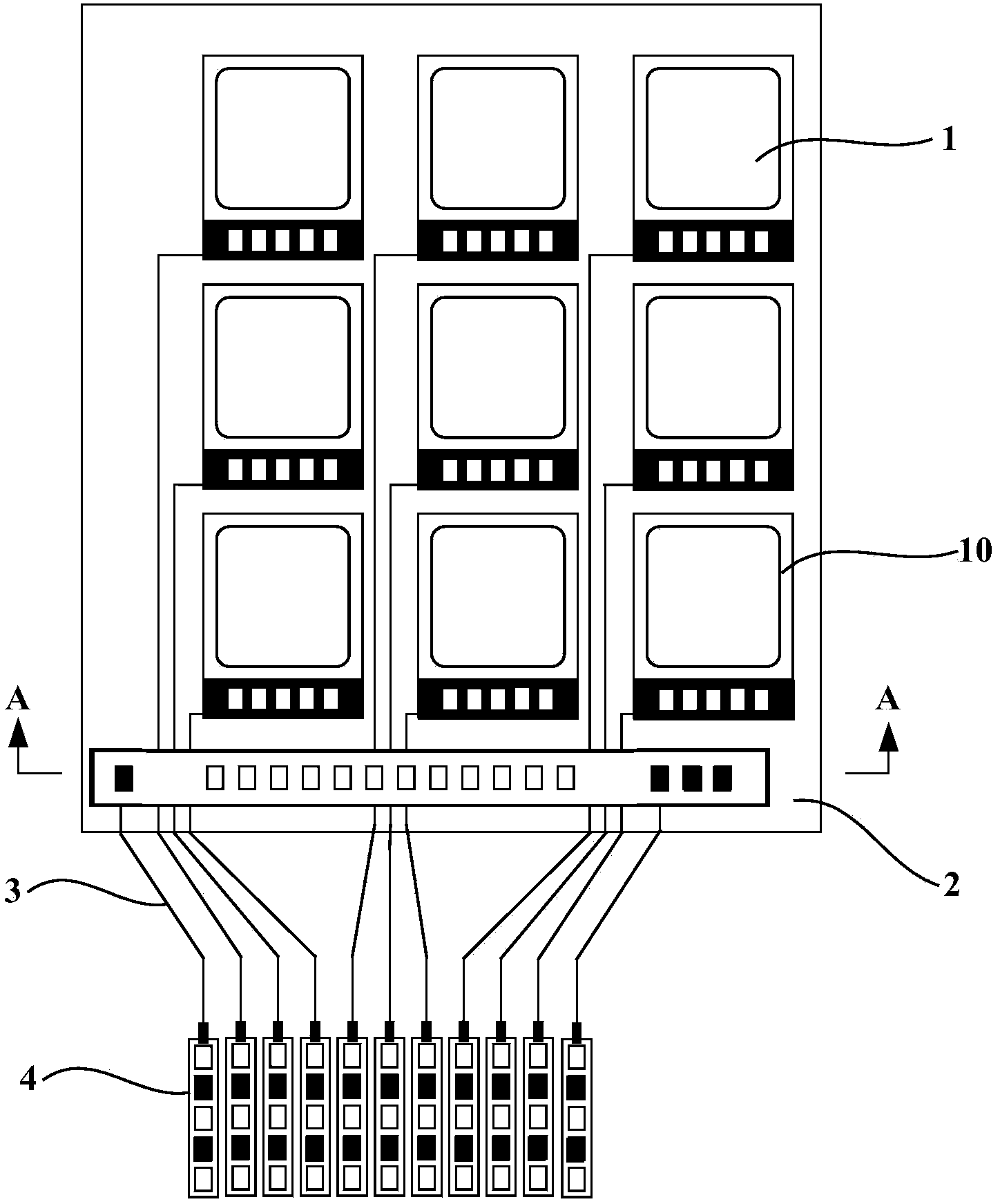

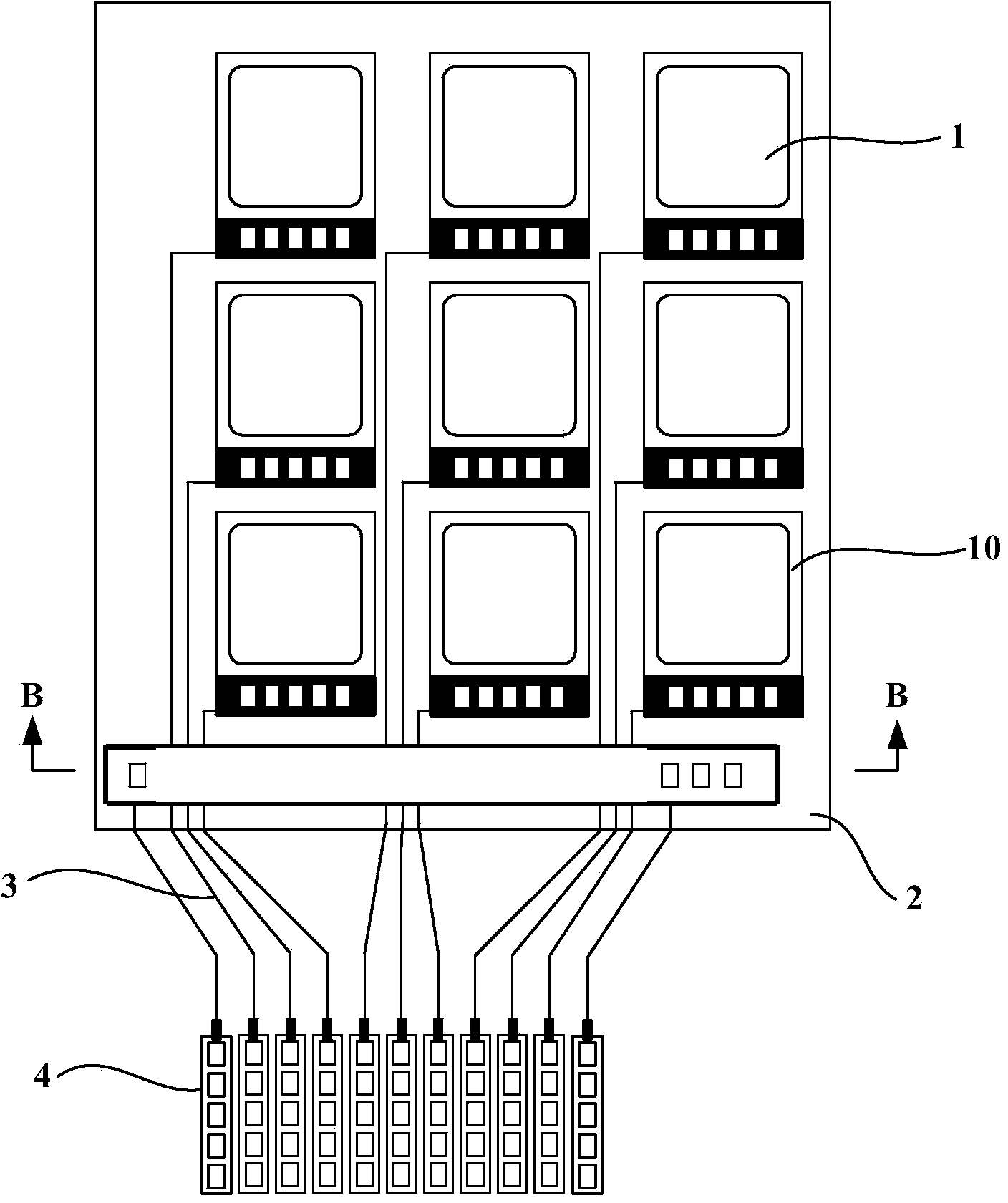

[0055] Such as image 3 with Figure 4 As shown, the passive matrix organic light emitting d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com