High-voltage switch cabinet for electrification indicating of shell

A high-voltage switchgear and live indication technology, applied in the field of switchgear, can solve the problems of insufficient space and large space, and achieve the effects of low manufacturing cost, increased protection level, and increased scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

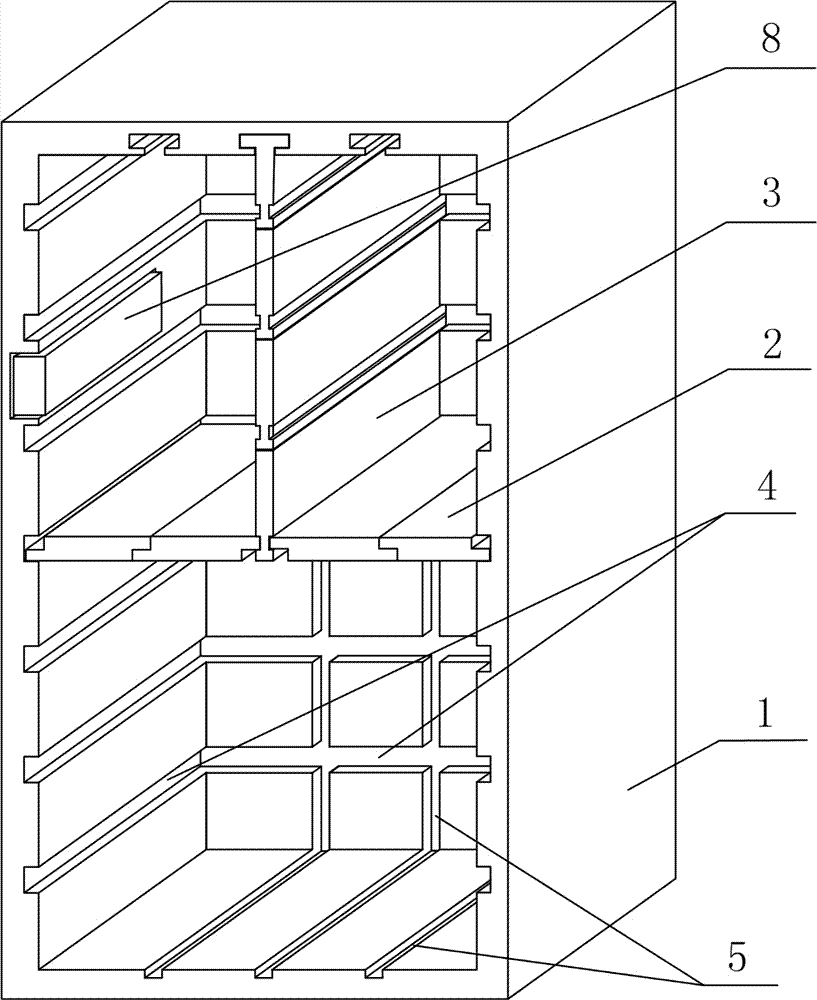

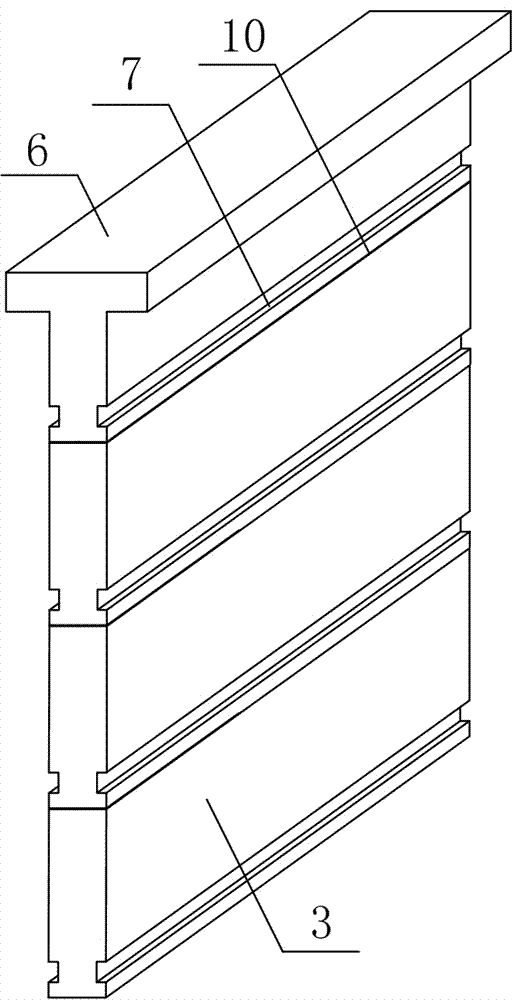

[0034] A high-voltage switchgear for indicating live electricity on the shell, such as figure 1 , image 3 with image 3 As shown, it includes a switch cabinet body 1, and a horizontal partition plate 2 and a vertical partition plate 3 arranged in the switch cabinet cabinet body 1; the inner wall of the switch cabinet body 1 is provided with a horizontal partition for placing the horizontal partition plate 2 Slot 4, the inner wall of the switchgear body 1 is also provided with a vertical placement groove 5 for placing the vertical partition 3; the cross section of the groove at the top of the vertical placement groove 5 is an inverted "convex" shape, and the vertical partition The top of the plate 3 is provided with a protruding piece 6 matching the inverted “convex” shape; the side wall of the vertical partition 3 is also provided with a connecting groove 7 corresponding to the position of the horizontally placed groove 4.

[0035] In order to detect whether there is a leakage of...

Embodiment 2

[0042] The difference between this embodiment and embodiment 1 lies in the optimization of the specific structures of the transverse partition 2 and the vertical partition 3, and the specific settings are as follows:

[0043] A broken crack 10 is also provided at a position 0.2-2 cm below the connecting groove 7 on the vertical partition 3. Through the setting of the broken crack 10, the height of the vertical partition 3 can be manually adjusted without any tools, thereby simplifying the operation steps.

[0044] The vertical placement grooves 5 are evenly distributed on the inner wall of the switch cabinet body 1, and the width of the transverse partition plate 2 is the same as the distance between two adjacent vertical placement grooves 5.

[0045] In the present invention, the number of vertical partitions 3 matching the number of vertical placement grooves 5 is configured, that is, when the number of vertical placement grooves 5 is N, the number of vertical partitions 3 is also ...

Embodiment 3

[0048] This embodiment further optimizes the setting method of the transverse partition 2 on the basis of the embodiment 2. The specific setting method is as follows:

[0049] The two ends of the transverse partition plate 2 are respectively provided with fasteners 11 for mutual cooperation, and the thickness of the fasteners 11 is the same as the height of the connecting groove 7. The depths of the connecting groove 7 and the horizontal placement groove 4 are h1 and h2, respectively, and the width of the fastener 11 is l, then l> h1, l> h2, l <h1+ h2.

[0050] Through the above arrangement, the stability of the present invention after installation is effectively increased.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com