Electric variable-frequency high-voltage cable conveying construction technology

A construction process and high-voltage cable technology, which is applied in the direction of cable laying equipment, the use of reel take-up reels/photosensitive drums, etc., can solve the safety hazards of surrounding personnel and equipment, and the internal damage of cables, so as to reduce safety hazards. , speed up the construction speed, the effect of improving the speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below with reference to the drawings and specific embodiments. The following embodiments are only descriptive and not restrictive, and the protection scope of the present invention cannot be limited by this.

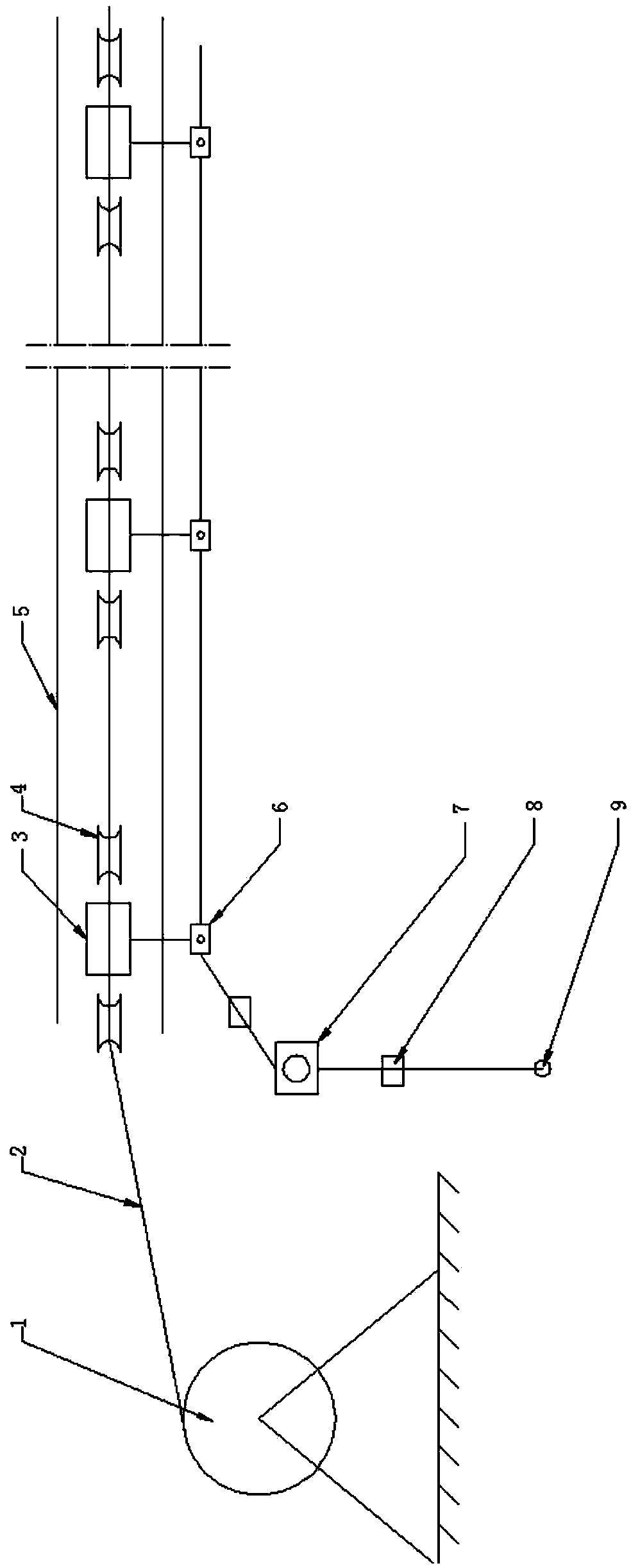

[0024] An electric variable frequency high-voltage cable transportation construction technology, the steps are as follows:

[0025] (1) Prepare the cable, set up the cable release device according to the preset cable site, use the cable shaft to erect the cable shaft, the direction of the cable is the same as the direction of the groove to be laid;

[0026] (2) The interval between the arrangement of cable conveying equipment is 25 to 30 meters, and the cable conveying equipment shall be in a straight line;

[0027] (3) Arrange the cable pulley between the cable conveyors, the distance of the pulley is less than 7 meters;

[0028] (4) Connect the power supply of the sub-control box of the cable conveyor to the main c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com