Epoxy adhesive composition

A technology of epoxy adhesive and hardener composition, applied in the direction of adhesive type, adhesive, epoxy resin, etc., can solve the problems of reducing residual stress, fluidity loss, low residual stress, etc., to improve toughness , the effect of high adhesion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 and 2

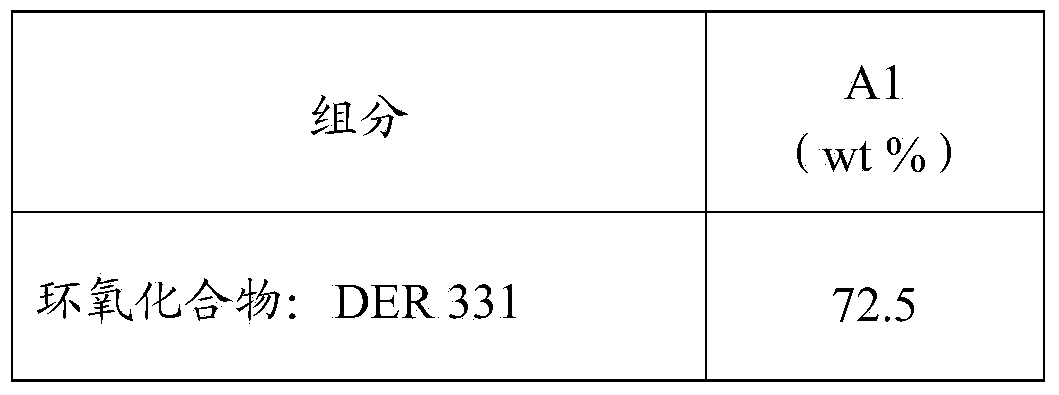

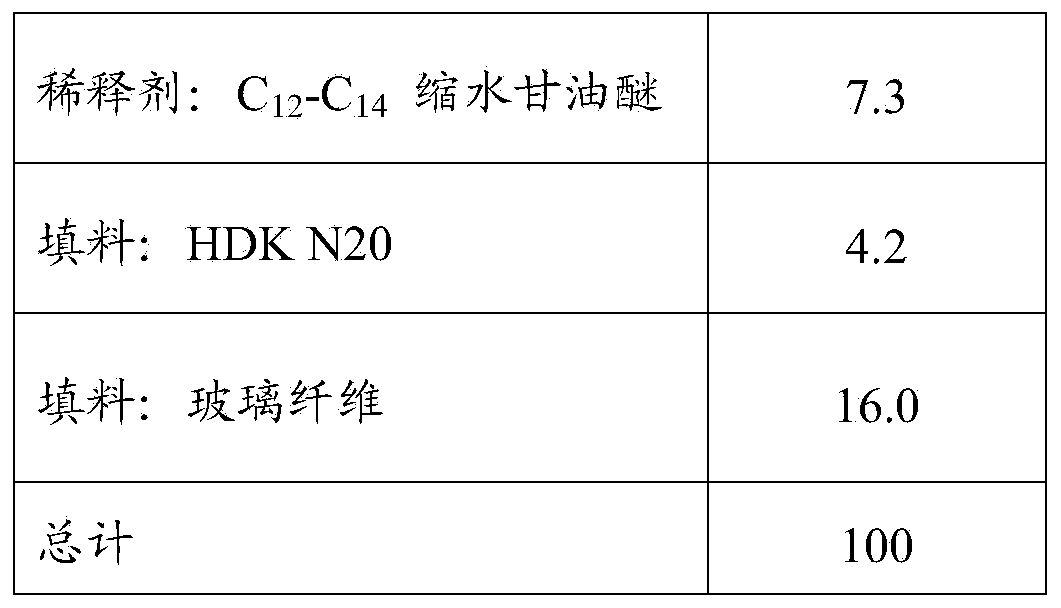

[0131] The curable compositions of the present invention (Examples 1 and 2) were prepared by combining a resin component and a hardener component to form a curable composition. Table V shows the curable compositions of Examples 1 and 2, which constitute formulated adhesive compositions, based on the weight ratio of the resin component to the hardener component.

[0132] Table V

[0133]

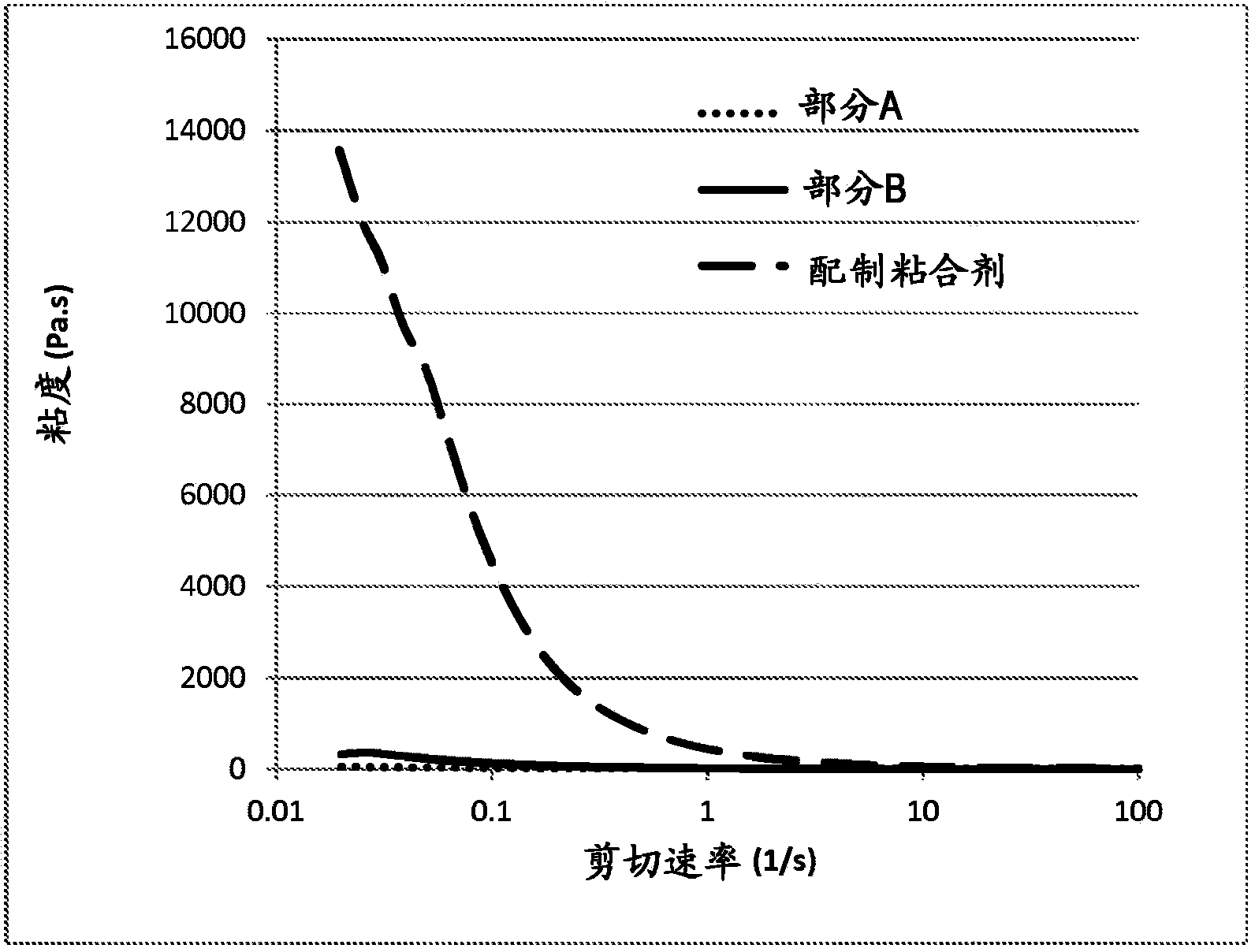

[0134] figure 1 The rheology of the inventive adhesive composition of Example 1 is shown in . figure 1 A graphical illustration of the formulated adhesive of Example 1 and the viscosity profile of the individual components is shown in . The epoxy resin and hardener components in the composition of Example 1 have relatively low viscosity and exhibit near Newtonian fluid behavior. However, the adhesive mixture is highly viscous and sag resistant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| residual stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com