Spreadable processed cheese and preparation method thereof

A processed cheese and spreadable technology, applied in cheese substitutes, dairy products, applications, etc., can solve the problems of poor texture, poor taste and spreadability, etc., and achieve the effect of moderate texture and good spreadability

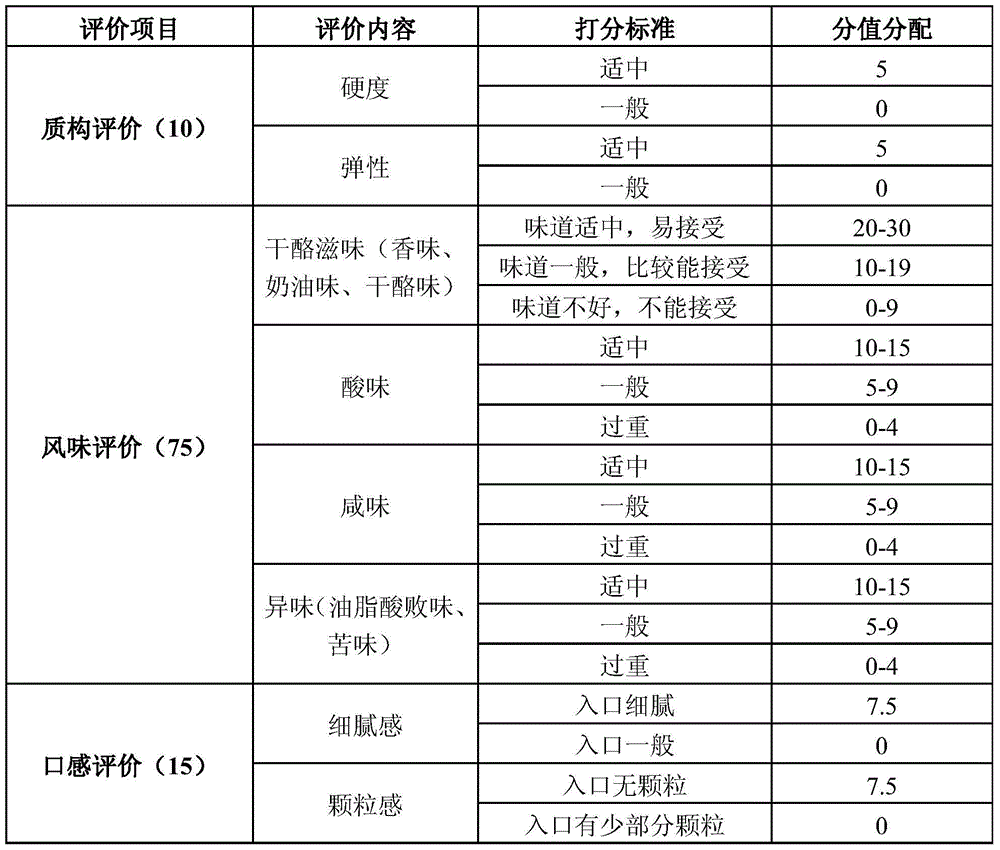

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] In yet another aspect, the present invention also provides a method for preparing the above-mentioned spread-type processed cheese, wherein the method includes:

[0026] (1) mixing natural cheese, caseinate, emulsifying salt, skim milk, whey, fat product, locust bean gum and part of water to obtain a mixed material;

[0027] (2) Melting the mixed material, and adding the remaining part of water to the melted mixed material.

[0028] The inventors of the present invention found that adding water into two parts to prepare the spreadable processed cheese can effectively improve the texture properties, smooth taste and spreadability of the cheese. Preferably, the part of water added first accounts for 60-70% by volume of the total water consumption.

[0029] According to the present invention, in step (1), the conditions and methods for mixing the above raw materials are not particularly limited, as long as they can be fully mixed, the present invention will not repeat the...

Embodiment 1-5

[0042] Table 1

[0043] Example 1 Example 2 Example 3 Example 4 Example 5 Natural cheese (parts by weight) 100 100 100 100 100 Sodium caseinate (parts by weight) 12.5 10 15 5 20 Emulsifying salt (parts by weight) 3 2.5 3.5 4 2 Skimmed milk powder (parts by weight) 8 9 9 6 10 Whey powder (parts by weight) 10 12.5 15 20 8 Anhydrous butter (parts by weight) 10 12 8 5 15 Locust bean gum (parts by weight) 0.3 0.35 0.4 0.1 0.5 water (parts by weight) 137.5 135 145 150 130

[0044]According to the content of each component in Table 1, the spreadable processed cheese is prepared, wherein the natural cheese is a natural cheese with a maturation period of 3-4 months, and the emulsifying salt is phosphoric acid with a weight ratio of 3:3:2 Disodium Hydroxide, Sodium Tripolyphosphate and Sodium Citrate. The specific process of preparation is:

[0045] First cut the cheese into 5-10cm 3...

Embodiment 1、4 and 5

[0047] Examples 1, 4 and 5: the part of water added at first accounted for 65% by volume of the total water; the melting temperature was 85°C, the stirring speed was 200rpm, and the time was 12min; the pH value was adjusted by lactic acid to 5.4;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com