Low energy and low fat processed cheese slice/block, and preparation method thereof

A processed cheese, low-fat technology, applied in low-fat flake or block processed cheese, low-energy field, can solve the problems of unfull taste, poor flavor, low energy, etc., and achieve suitable viscosity and strong flavor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Ingredients: fresh cheddar cheese (47.4% fat in dry matter) 25%; whey protein concentrate WPC 806%; sodium citrate 1%; sodium pyrophosphate 1%; cream 8%; skimmed milk powder 4%; Fat milk powder 3%; tapioca modified starch 2%; inulin 2%; carrageenan 0.1%; locust bean gum 0.1%; konjac gum 0.1%; salt 0.3%; 0.3%; sorbic acid 0.09%; water 48.71%.

[0035] Preparation:

[0036] ① Cut the natural cheese into small pieces of (2×2) cm, add the rest of the raw materials according to the above ratio, put them into the melting pot, and use a sharp knife to cut and mix at a shear speed of 900rpm;

[0037] ②Heating the raw material to 90°C with a shear rate of 900rpm;

[0038] ③ When the temperature reaches 90°C, emulsify for 5 minutes;

[0039] ④ Pour out the sample, fill it, and cool it down to room temperature rapidly.

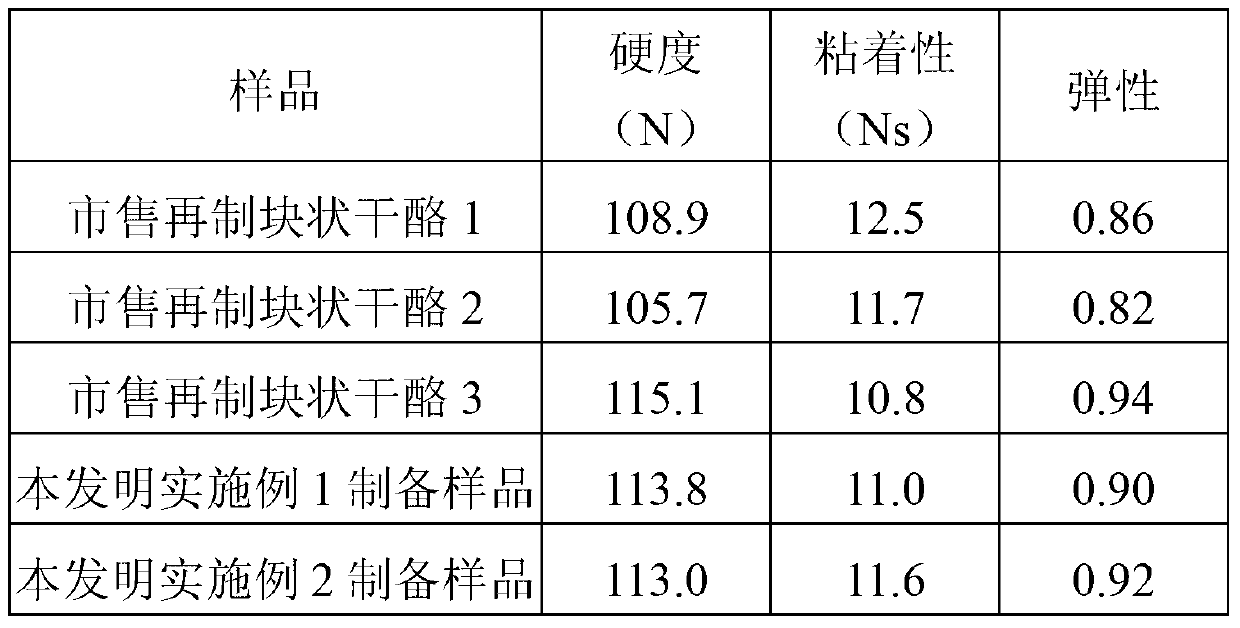

[0040] The texture was measured and the results were as follows: fat 8.48%; protein 10.72%; water 64.27%; carbohydrate 9.16%; energy 633.87kJ / 100g;

Embodiment 2

[0042] Ingredients: Primost ricotta (maturity 2 months) 12%; rennet casein 4%; whey protein concentrate WPC 806%; sodium citrate 1%; cream 10%; skimmed milk powder 8%; inulin 3 %; polydextrose 2%; carrageenan 0.2%; konjac gum 0.1%; xanthan gum 0.2%; salt 0.4%;

[0043] Production method:

[0044] ① Cut the ricotta cheese into small pieces (2×2) cm, add the rest of the ingredients according to the above ratio, put it into the melting pot, and mix it with a sharp knife at a shear speed of 1000rpm;

[0045] ②Heating the raw material to 80°C with a shear rate of 1000rpm;

[0046] ③ When the temperature reaches 80°C, emulsify for 10 minutes;

[0047] ④ Pour out the sample, fill it, and cool it down to room temperature rapidly.

[0048] The measurement results are as follows: fat 8.9%; protein 14.98%; moisture 63.96%; carbohydrate 10.8%; energy 741.21kJ / 100g;

Embodiment 3

[0050] Ingredients: Part-skimmed mozzarella (maturity 6 months, fat content in dry matter 40%) 10%; whey protein concentrate WPC80 15%; sodium citrate 1%; sodium pyrophosphate 1%; cream 3%; Whole milk powder 5%; potato modified starch 5%; inulin 1%; carrageenan 0.2%; xanthan gum 0.2%; salt 0.3%;

[0051] The preparation method is the same as in Example 1.

[0052] The measurement results are as follows: fat 6.9%; protein 16.0%; moisture 62.5%; carbohydrate 11.9%; energy 721.1kJ / 100g;

[0053] The beneficial effects of the present invention will be further illustrated below through effect examples.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com