The processing method of using resistant dextrin to produce bayberry candied fruit

A technology of resistant dextrin and processing method, applied in the application, confectionery industry, food science and other directions, can solve the problems of poor control, small molecular weight, and the promotion effect cannot meet the needs of the process, and achieves uniform texture and complete tissue structure. , Maintain the effect of the original nutritional and health care ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Dissolve 75 kg of sucrose and 100 kg of resistant dextrin with about 400 liters of pure water, and make up to 500 liters with purified water to form 500 liters of soaking liquid containing 15% of sucrose and 20% of resistant dextrin. In the two-way airtight 1000 liter soaking and soaking equipment, heat up to 50-60°C; add 300 kilograms of desalted small fruit type and medium fruit type (the diameter of fresh red bayberry is 2.0 cm to 2.5 cm) in the soaking soaking equipment. Blank (red bayberry salted blank refers to the red bayberry harvested in the production season with a maturity of about 60-70%, and the raw material preserved with 20% salt), turn off the soaking and infiltration equipment, first evacuate to below 10kPa, maintain 3-5min, and then use Break the vacuum in 1.5 minutes, pressurize to 170-200kPa and maintain for 3-5 minutes, then release the pressure in 1.5 minutes, repeat 2 times. Add 50 kg of resistant dextrin to the tank after the first decompression-...

Embodiment 2

[0024] Greater than 2.5 centimeters for the large-scale salted base of fresh red bayberry, need to operate by the process parameter and the condition of embodiment 1, but process is repeated 3 times, during each decompression-pressurization cycle finishes adding the resistance in tank The dextrin is changed to 25 kg, and the whole process takes about 60 minutes to obtain a semi-finished product of bayberry candied fruit that is uniformly soaked.

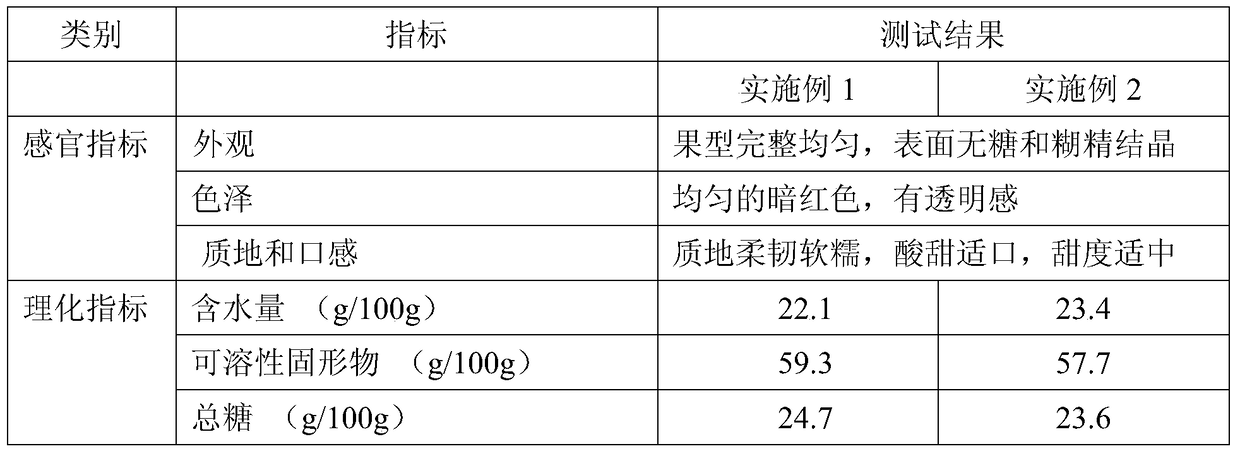

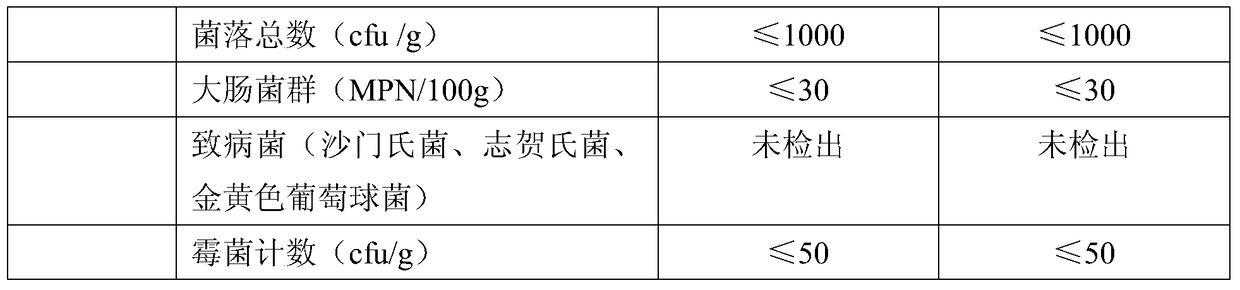

[0025] The above-mentioned semi-finished products are dried with hot air at 50-70°C until the water content is about 20%, and then softened after standing at room temperature, and then packed in grades to become finished products. The sensory, physicochemical and microbiological indicators of the finished product are as follows, in line with GB14884-2003 hygienic standard for candied fruit.

[0026] Table 1 The quality indexes of trial-produced low-sugar bayberry samples in two implementation cases

[0027]

[0028]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com