A rapid cooling pressure cooking device

A cooking device and rapid cooling technology, applied to pressure cookers, cooking utensils, household appliances, etc., can solve the problems of increasing product power consumption, complex air-cooling structure, and increasing the cost of accessories

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

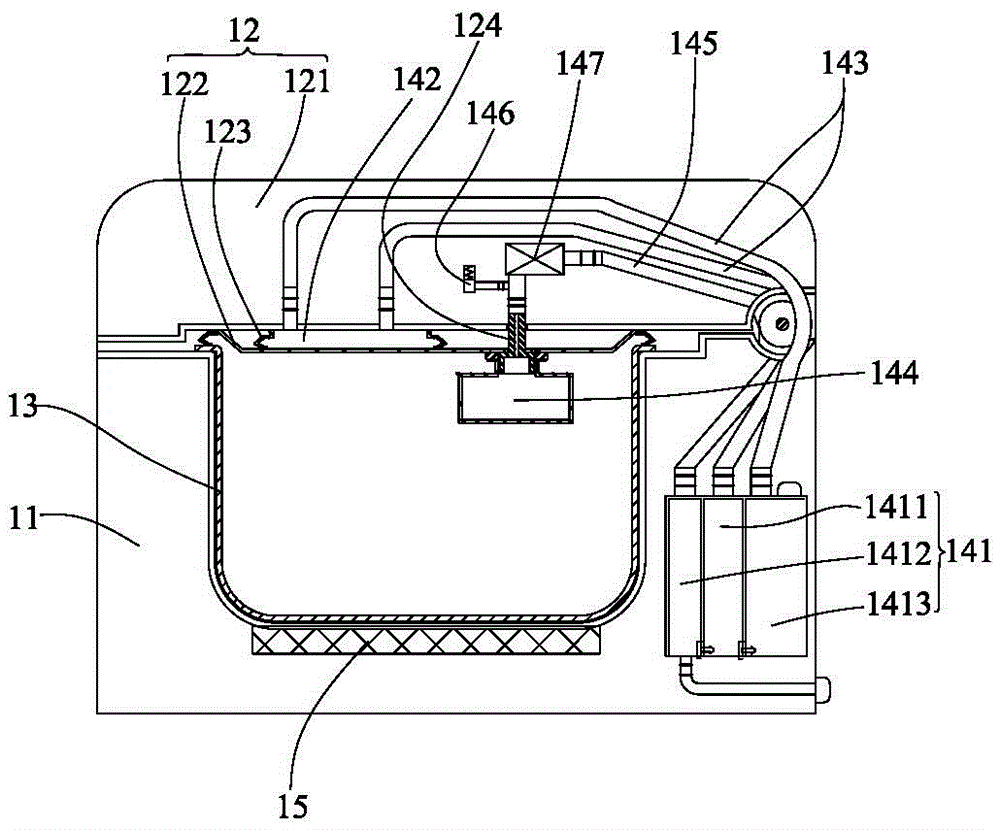

[0032] see figure 1 As shown, the first embodiment of a rapid cooling pressure cooking device of the present invention includes a pot body 11, a pot cover 12, an inner container 13, a cooling device and a heating device 15 located at the bottom of the pot body, and the inner container 13 is placed on the pot body In 11, pot cover 12 comprises outer cover 121 and inner cover 122, and pot cover 12 fastens airtight liner 13, and cooling device comprises the water tank 141 that cooling water is housed, cooling chamber 142, the circulating water pipe 143 that communicates water tank and cooling chamber. The cooling device also includes a steam pressure chamber 144, the steam pressure chamber 144 is installed on the inner cover 122, the steam pressure chamber 144 is provided with an exhaust pipe 145 communicating with the water tank 141, the heating device 15 heats the inner container 13, and the inner container 13 The high-temperature steam heats the steam pressure chamber 144, and...

Embodiment approach 2

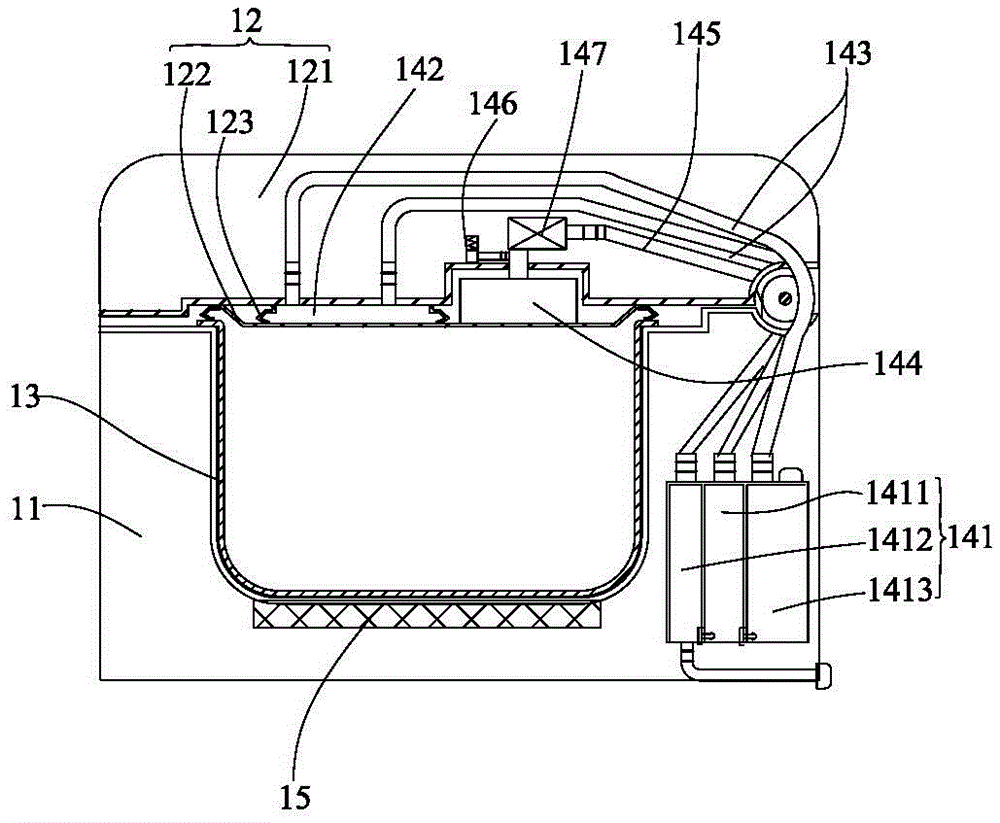

[0046] see image 3 As shown, the second embodiment of a rapid cooling pressure cooking device of the present invention differs from the first embodiment in that: the steam pressure chamber 144 and the cooling chamber 142 are installed on the same side of the inner cover 122 facing away from the inner container 13 on the side. In this way, the surface of the inner cover 122 facing the inside of the inner 13 is relatively flat, and the user can directly scrub the inner cover.

[0047] Certainly, the side of the inner cover 122 facing away from the liner can also be provided with a concave cavity, and the steam pressure chamber 144 is installed in the concave cavity.

[0048] The remaining structures and beneficial effects of this embodiment are consistent with those of the first embodiment, and will not be repeated here.

Embodiment approach 3

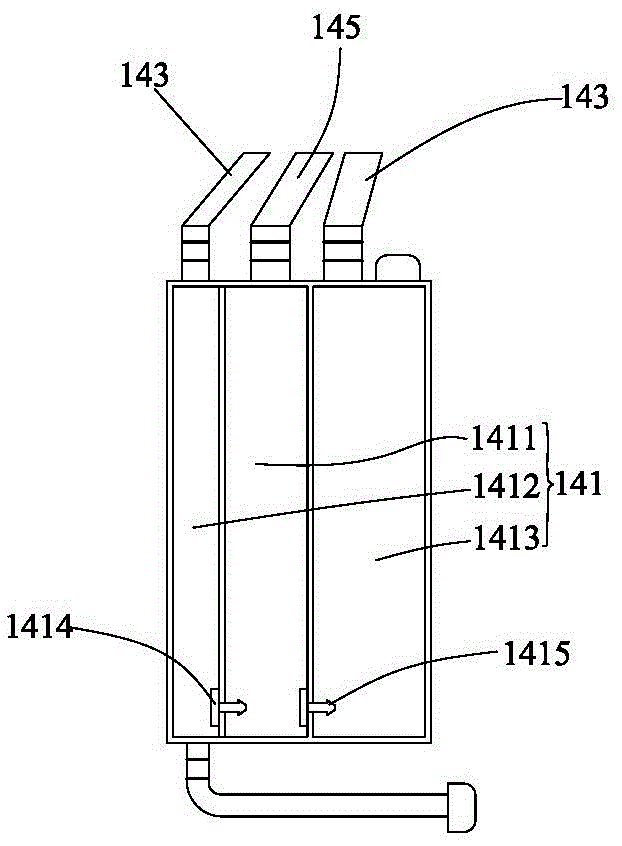

[0050] see Figure 4 As shown, the third embodiment of the rapid cooling pressure cooking device of the present invention differs from the first embodiment in that: the water tank 141 includes a sealed air intake water chamber 1411 connected to the steam pressure chamber 144 through the exhaust pipe 145 1. Return water cavity 1412, the bottom of the intake water cavity 1411 is connected to the cooling cavity 142 through the circulating water pipe 31, the top of the return water cavity 1412 is connected to the cooling cavity 142 through the circulating water pipe 31, and the return water cavity 1412 is provided with a single valve facing the intake water cavity to valve 32.

[0051] Further, a one-way valve is provided at the bottom of the inlet water chamber 1411 where it is connected to the circulating water pipe 31 to avoid water backflow.

[0052] In this embodiment, compared with the first embodiment, the circulating water pipe 31 directly replaces the water outlet cavity...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com