Patents

Literature

32results about How to "Guaranteed pressure safety" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

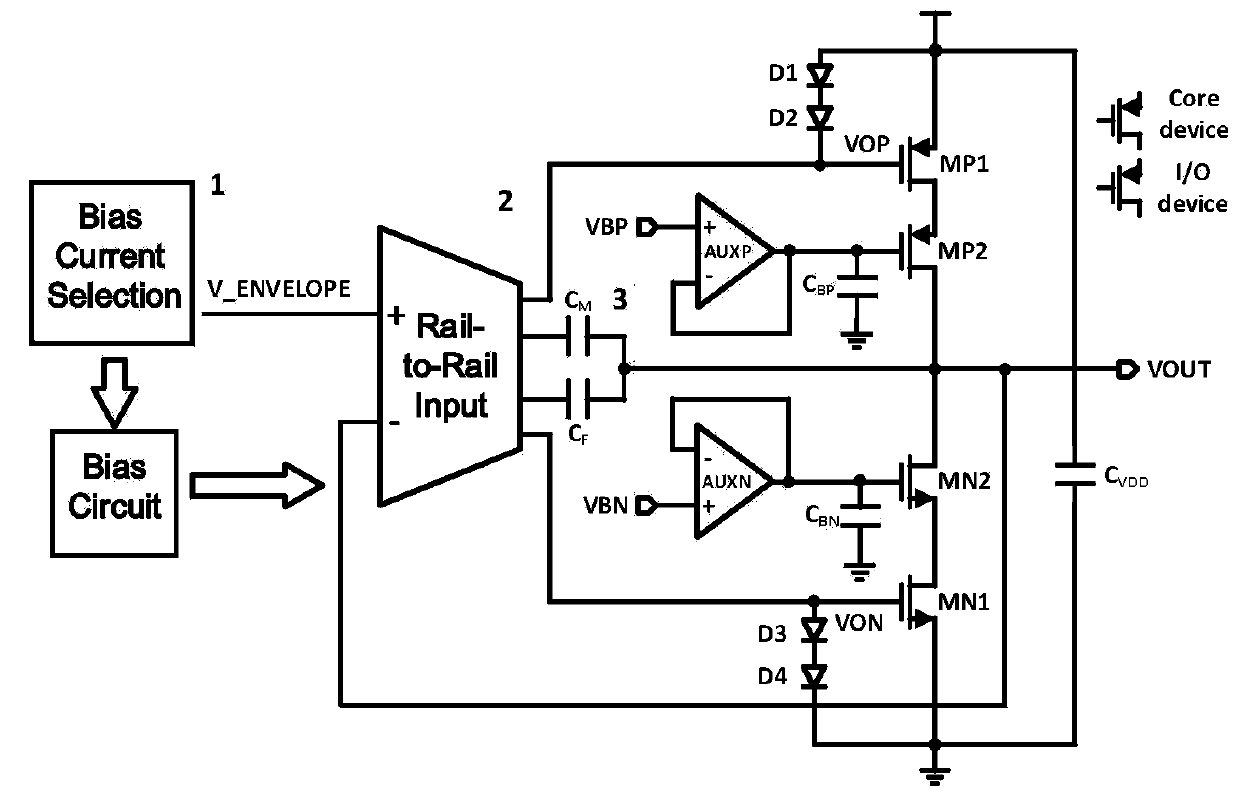

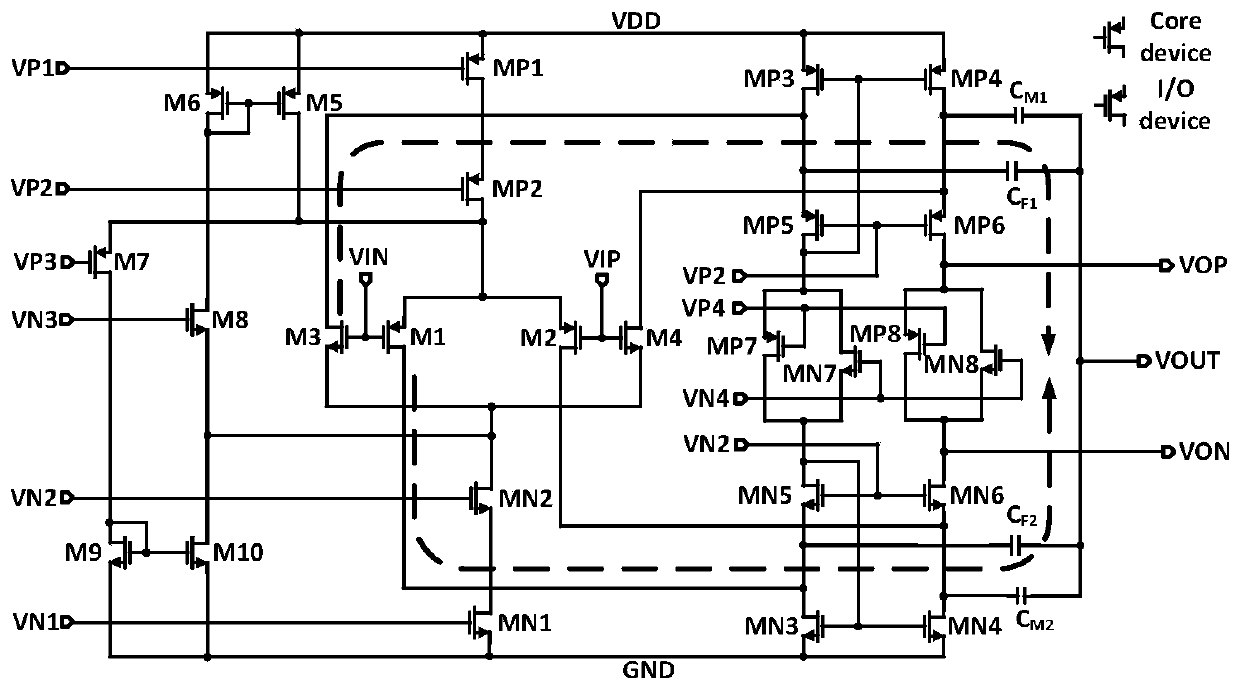

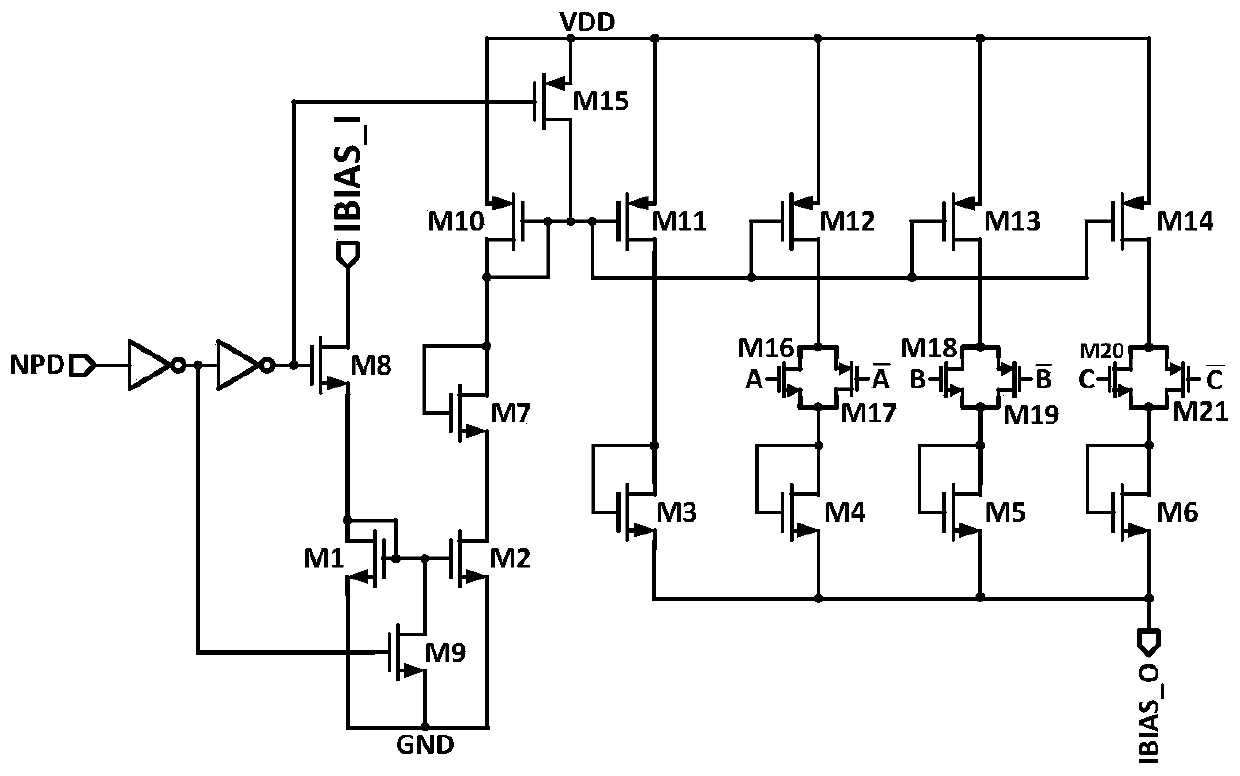

High-bandwidth high-swing linear amplifier applied to envelope tracking power supply modulator

ActiveCN110311636AFlexible choiceReduce power consumptionGain controlPower amplifiersCapacitanceCascode

The invention belongs to the field of integrated circuit design, and particularly relates to a high-bandwidth high-swing linear amplifier applied to an envelope tracking power supply modulator. The linear amplifier includes a bias circuit, an amplifier circuit, and a compensation circuit. The bias circuit is composed of a bias current selection module and a bias module. The first stage of the amplifier circuit is a rail-to-rail input folded cascode transconductance amplifier, and the second stage of the amplifier circuit is a Class-AB type amplifier. The compensation circuit adopts two compensation modes of CASCODE miller compensation and feedforward compensation. The Miller compensation capacitor realizes separation of primary and secondary poles. The feed-forward compensation capacitor can provide a feed-forward path for high-frequency signals, the bandwidth is expanded, and the high-frequency performance of the amplifier is improved. In addition, the feedforward compensation capacitor can solve the problem of high-frequency oscillation caused by packaged inductance introduced into the output end of the power supply modulator. And the Class-AB type output stage adopts a core tubeand I / O tube superposed structure. The linear amplifier can achieve tracking of envelope signals of LTE-100M at most, and the following dynamic range reaches 0.5 V-3V.

Owner:FUDAN UNIV

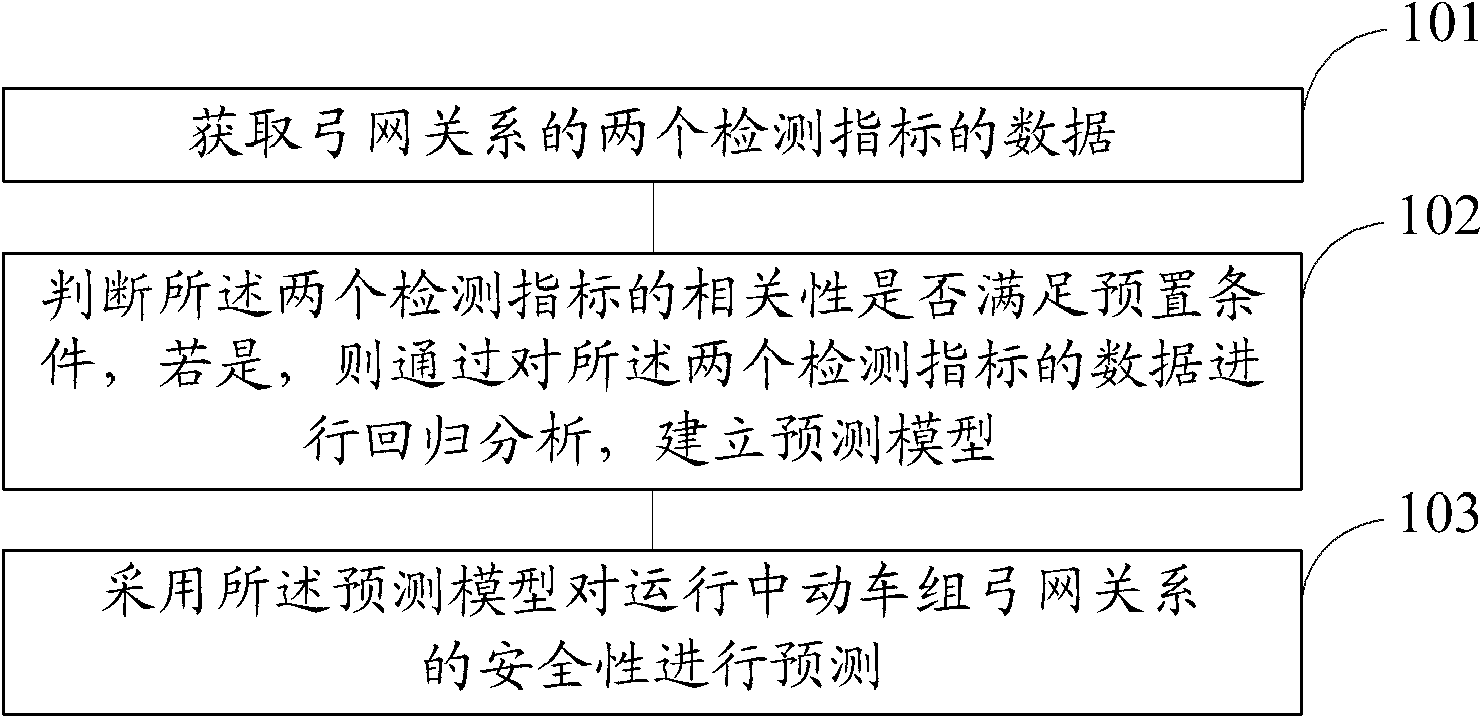

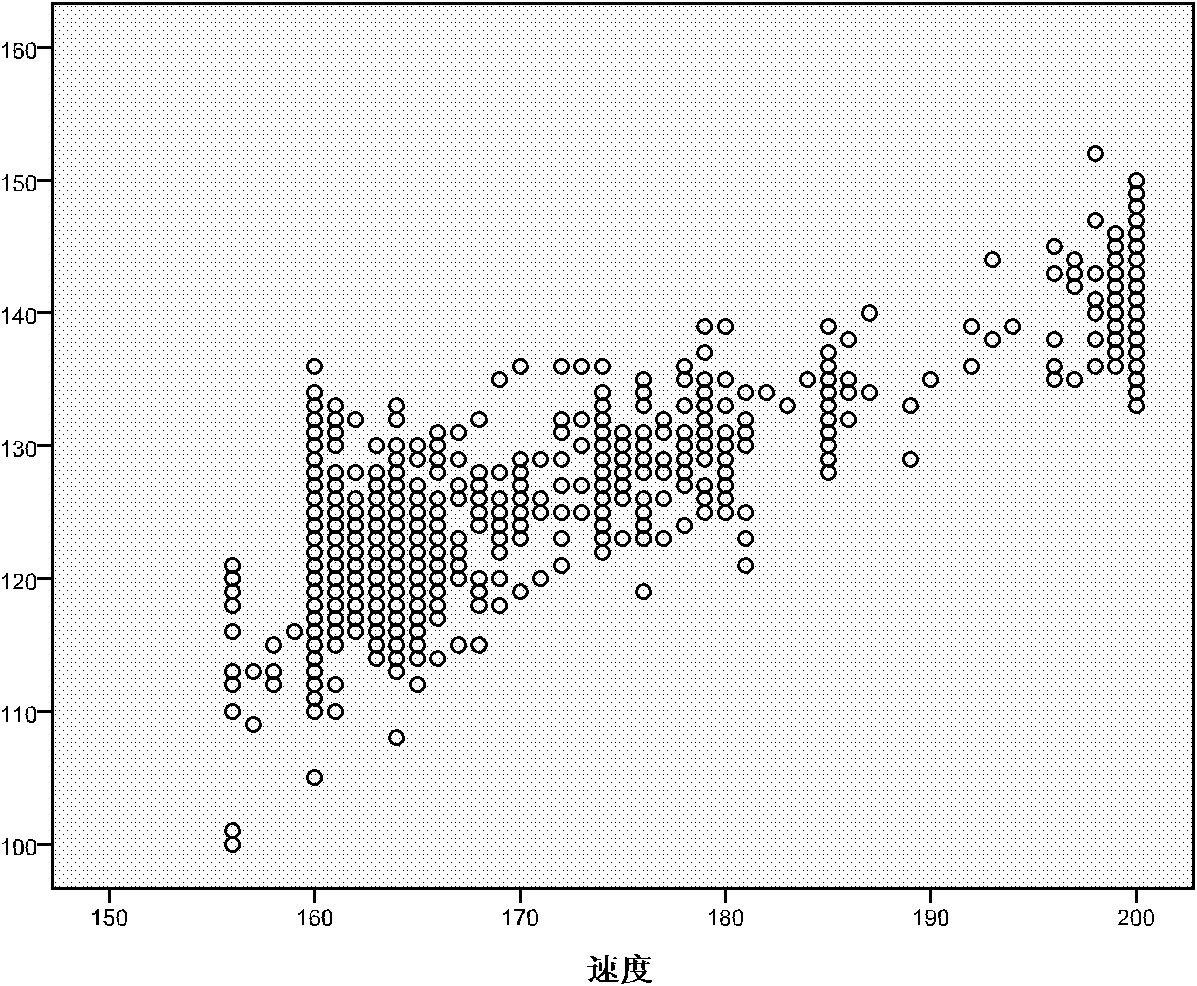

Safety prediction method of pantograph-catenary relationship of motor train unit

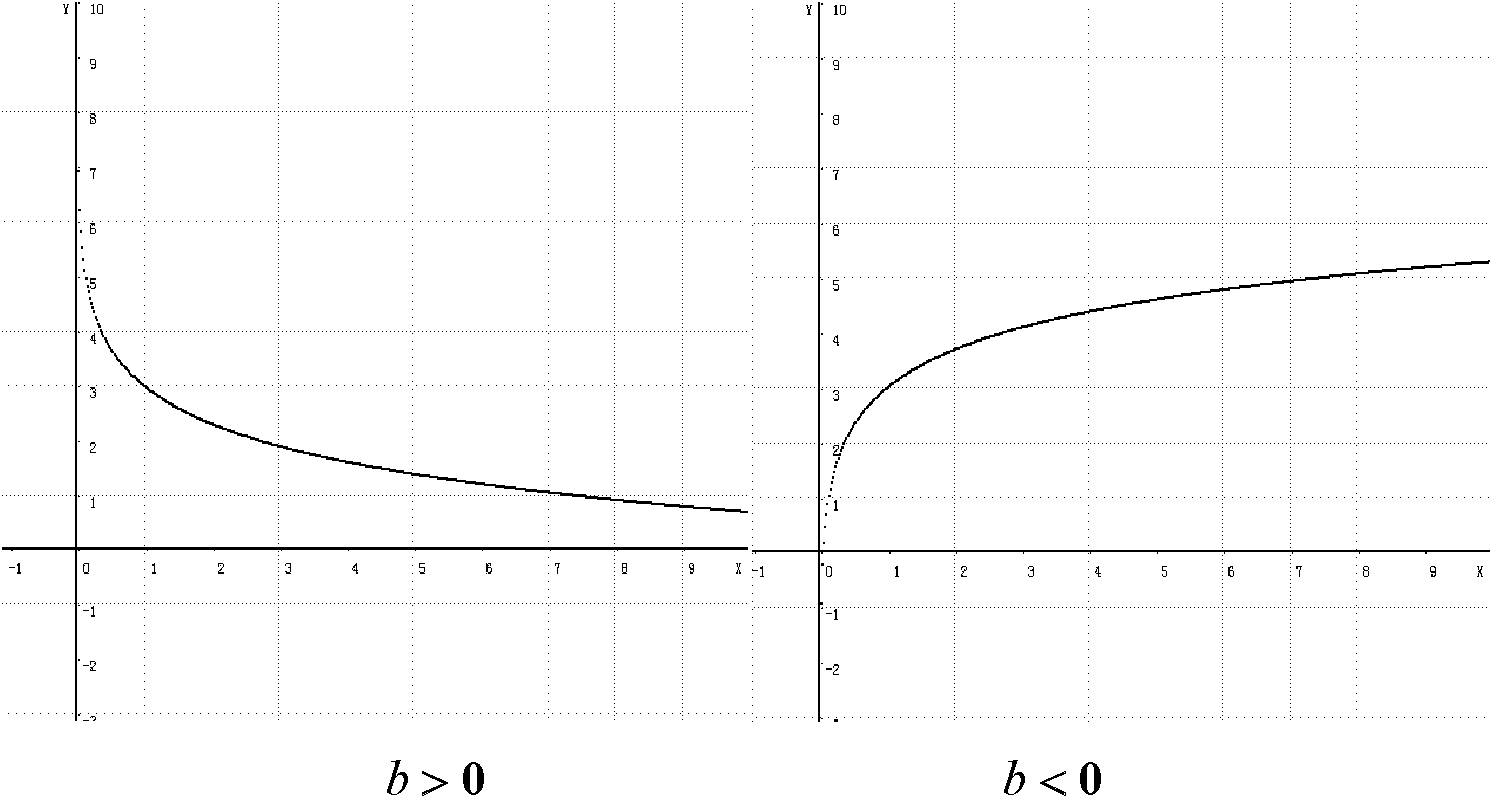

InactiveCN102222166APredict safetyImprove securitySpecial data processing applicationsRegression analysisPredictive methods

The invention provides a safety prediction method of a pantograph-catenary relationship of a motor train unit, which comprises the following steps: acquiring data of two detection indexes of the pantograph-catenary relationship; judging whether the relativity of the two detection indexes meets a preset condition or not, and if so, carrying out regression analysis to the data of the two detection indexes, and setting up a prediction model; and adopting the prediction model to predict the safety of the pantograph-catenary relationship of the motor train unit during running. By the method, the relationship between two detection qualities can be analyzed, so that the safety of the pantograph-catenary relationship of the motor train unit during running can be effectively predicted.

Owner:BEIJING JIAOTONG UNIV

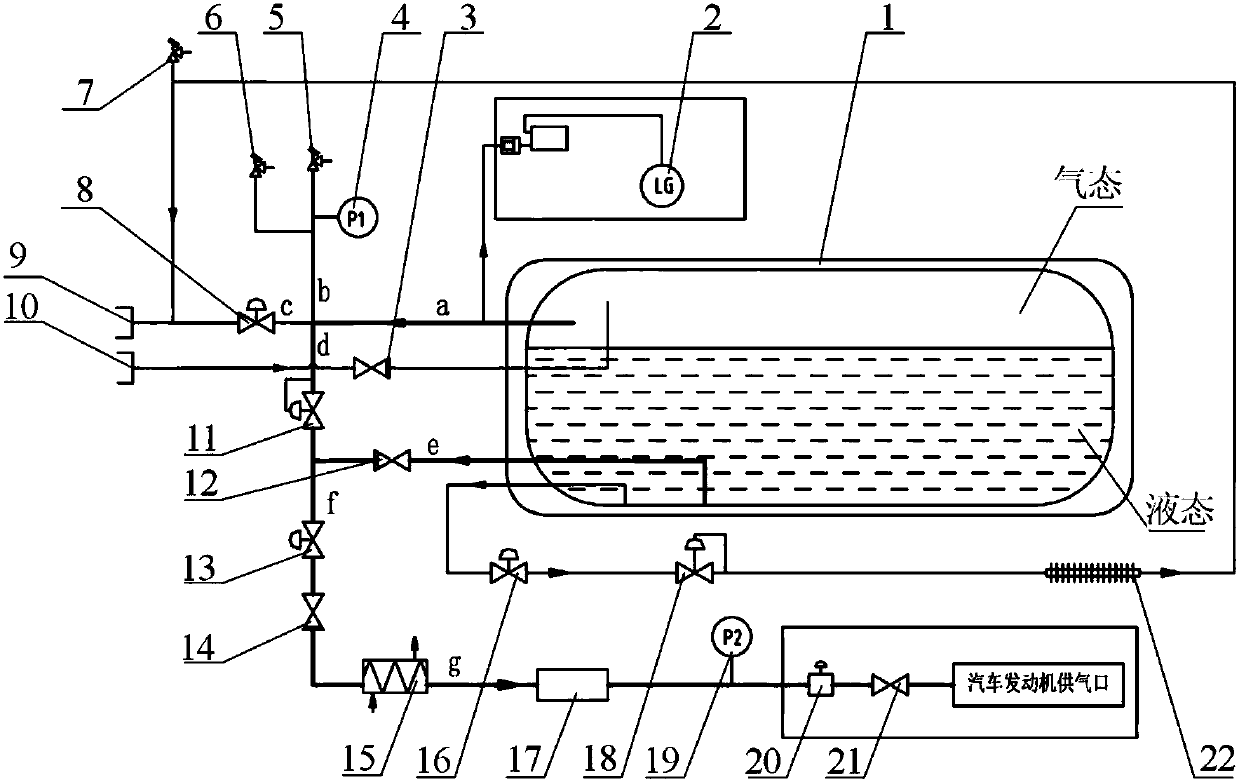

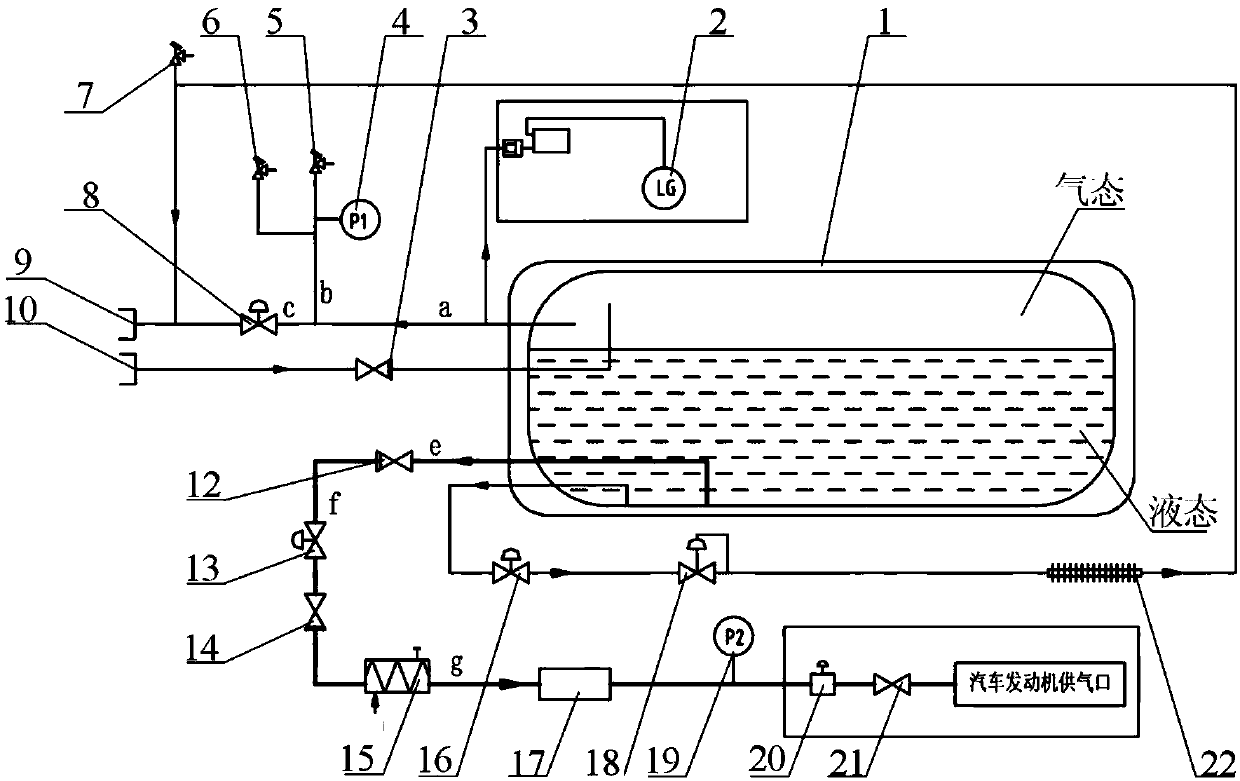

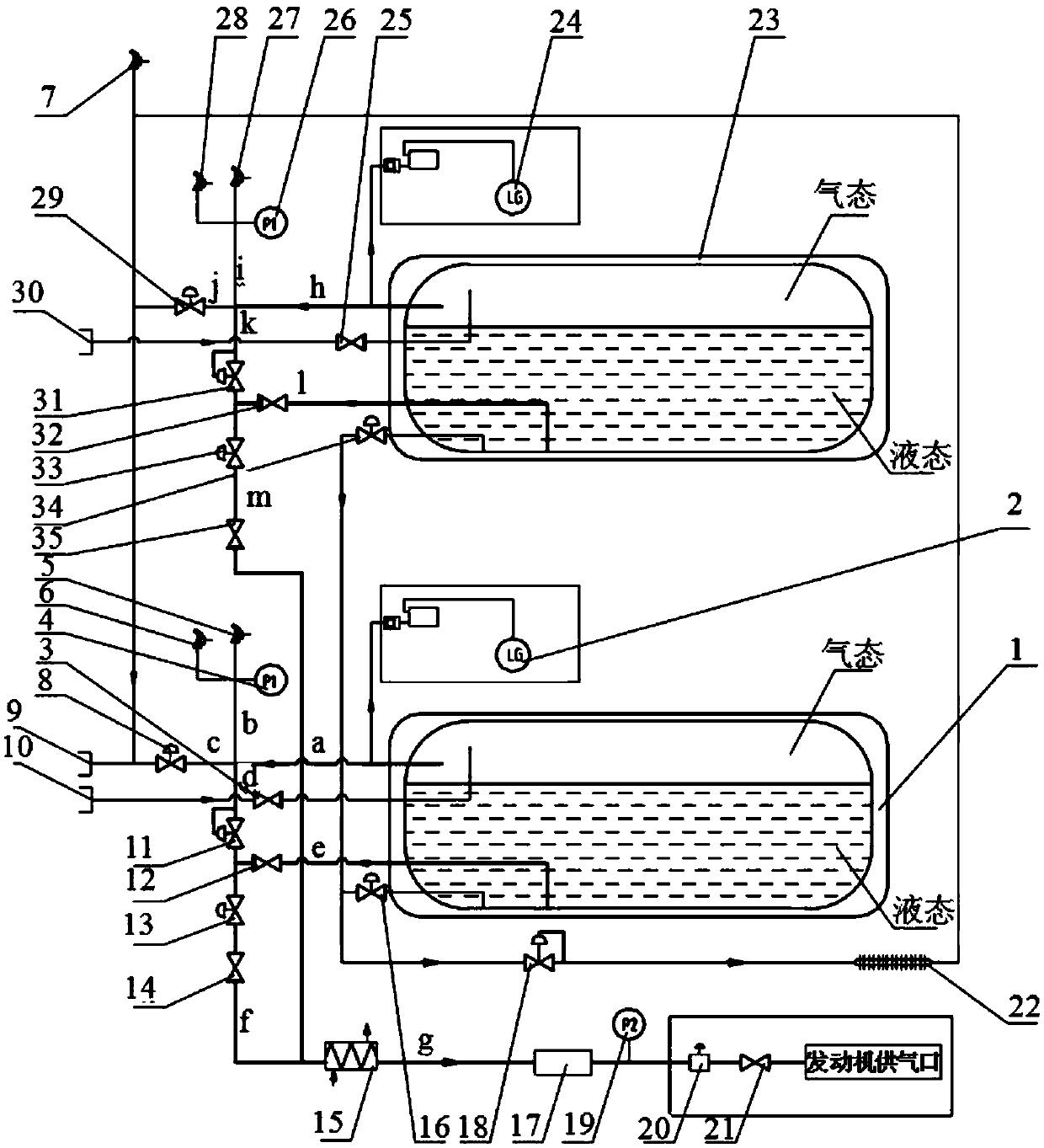

Novel automotive LNG gas supply system

InactiveCN107869411ALow priceReduce usageInternal combustion piston enginesFuel supply apparatusFailure rateGas cylinder

The invention provides an automotive LNG gas supply system. The automotive LNG gas supply system comprises a gas bottle assembly, a safety valve, a safety pressure relieving pipeline and an engine gassupply pipeline; the safety pressure relieving pipeline and the engine gas supply pipeline are connected to the gas bottle assembly, the safety valve is arranged on the safety pressure relieving pipeline, and the safety pressure relieving pipeline and the engine gas supply pipeline are independent and are not connected. Compared with a traditional automotive LNG gas supply system, the novel automotive LNG gas supply system removes arrangement of an economic valve and an economic valve connecting pipeline, direct supply through liquid LNG fuel is achieved, on the premise of ensuring the original safety of the whole gas supply system, the price and the failure rate of the automotive LNG gas supply system are greatly reduced, the superior economy is provided for a user, the system belongs tothe element omission invention, and the market popularization prospect is wide.

Owner:SHAANXI HEAVY DUTY AUTOMOBILE

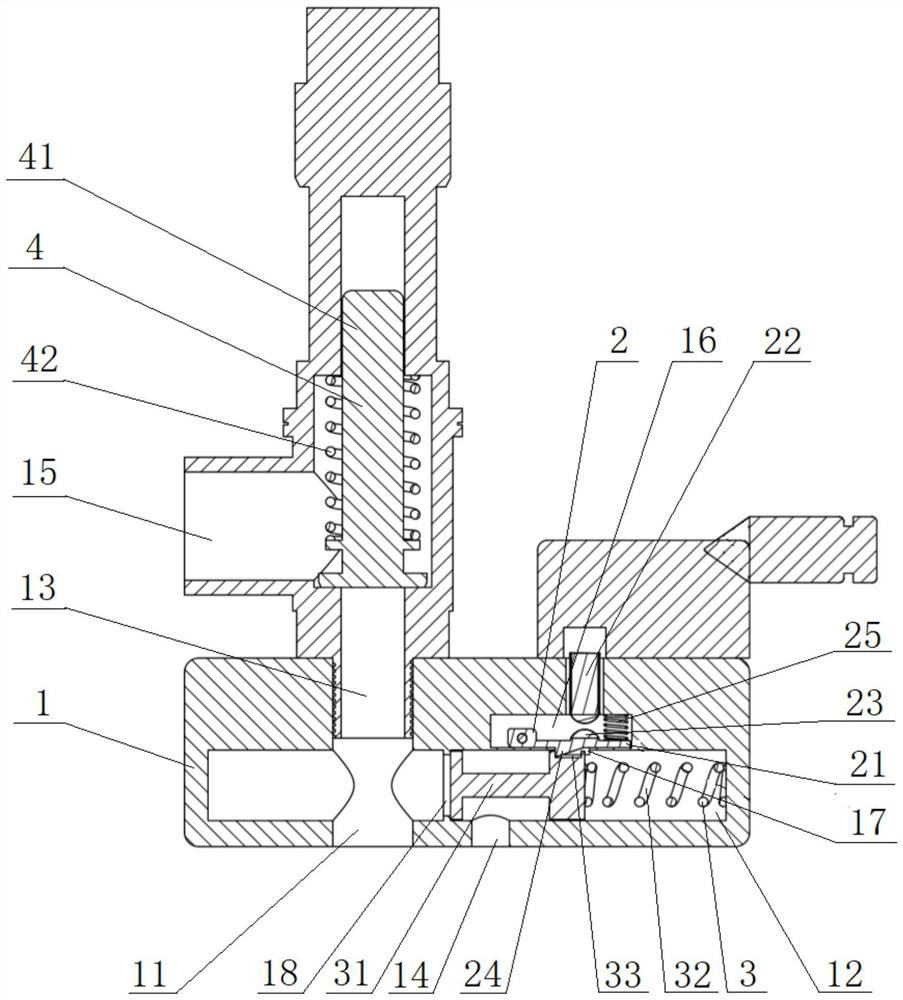

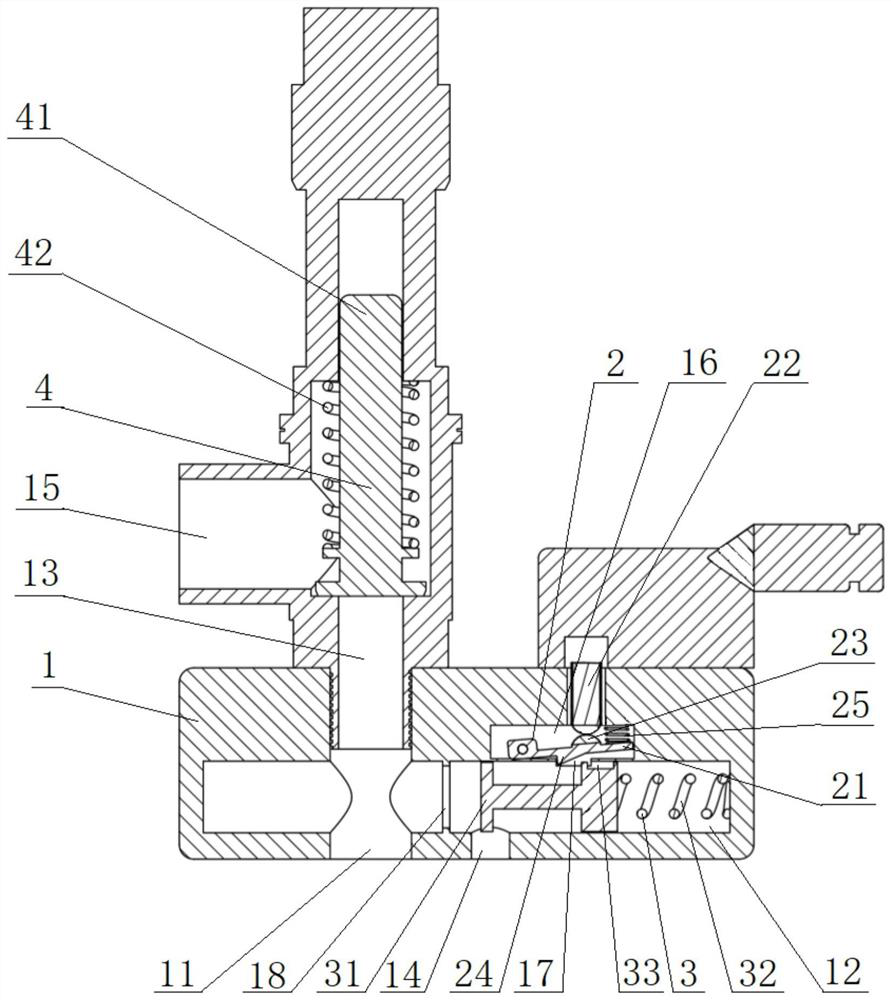

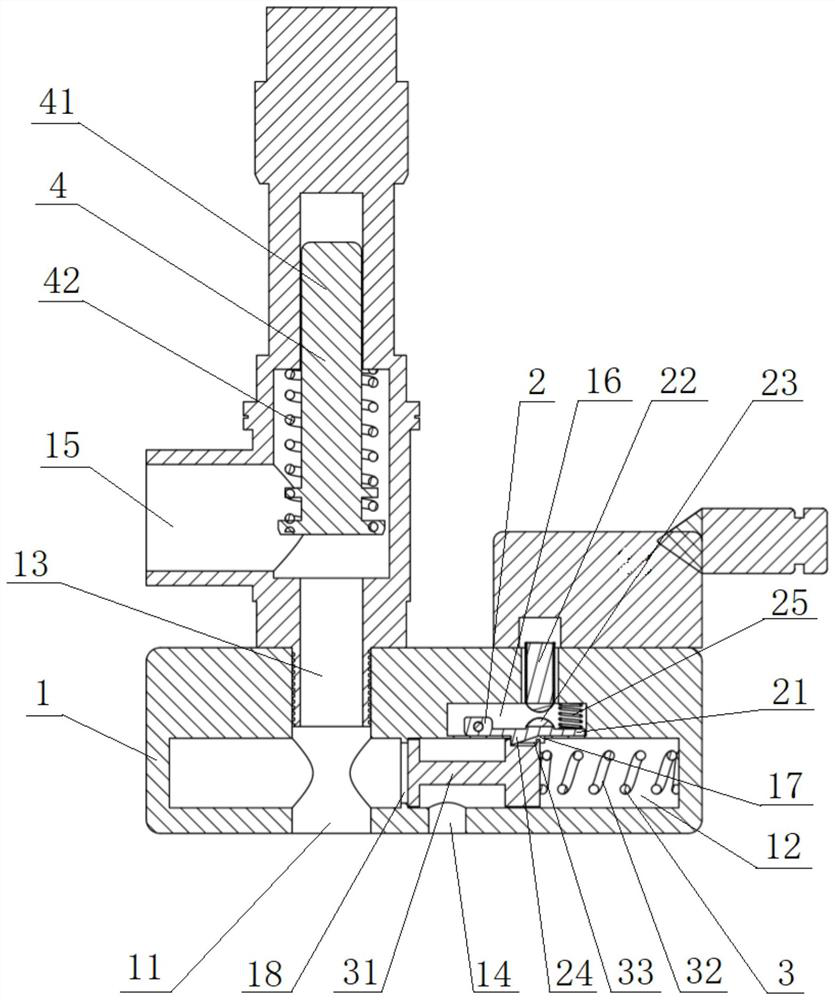

Railway vehicle carbon dioxide air conditioner safety valve and air conditioner system

PendingCN111720603AAvoid harmShort tripOperating means/releasing devices for valvesRailway heating/coolingRefrigerantSafety valve

The invention discloses a railway vehicle carbon dioxide air conditioner safety valve and an air conditioner system. The safety valve comprises a valve body, a locking assembly and a first pressure relief assembly, wherein a first channel is formed in the valve body, an air inlet connector and a first outlet are formed in the side face of the first channel, the first pressure relief assembly comprises a first valve element and a first pressure relief spring, the two ends of the first pressure relief spring abut against the valve body and a first valve element, the locking assembly is arrangedin the valve body and comprises a locking block and an electromagnet, the electromagnet is fixedly connected with the valve body, the locking block can be attracted by the electromagnet to move, a fixing protrusion is arranged on the locking block, the fixing protrusion can limit the first valve element, so that the first valve element blocks communication between the air inlet connector and the first outlet, and when the electromagnet is powered on, the electromagnet attracts the locking block, so that the fixing protrusion cancels limiting of the first valve element. According to the safetyvalve and the air conditioner system, the traditional passive pressure relief function is reserved, the safety valve can be actively opened according to the CO2 concentration, and refrigerant CO2 leakage is prevented.

Owner:CRRC DALIAN INST CO LTD

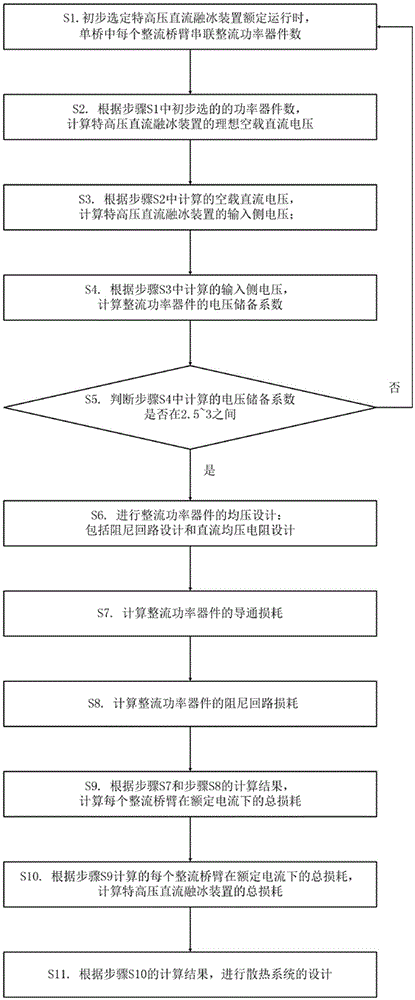

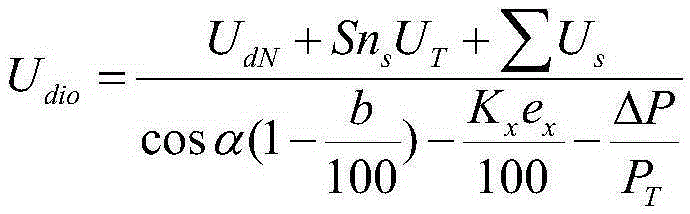

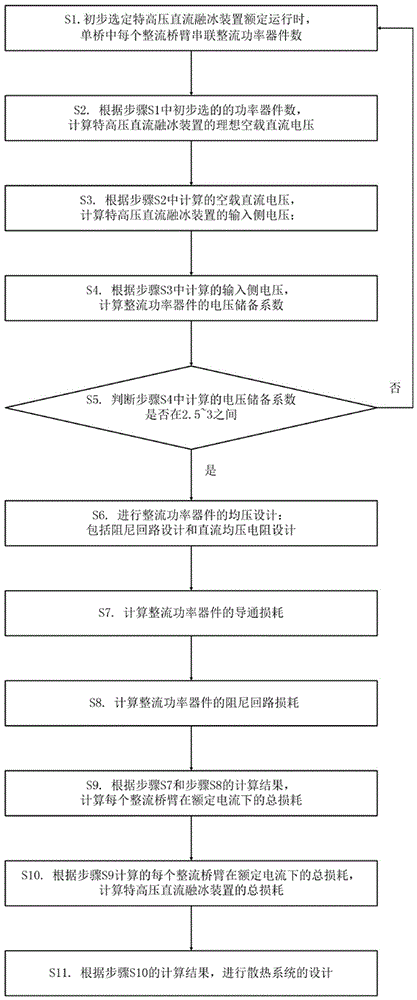

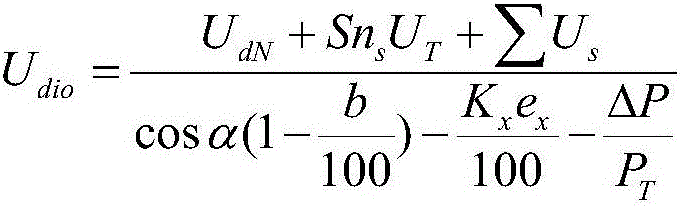

Air quantity determining method of meeting cooling requirements of extra-high voltage direct-current thawing device

ActiveCN105305354ADesign effective guidanceClear methodOverhead installationSpecial data processing applicationsAir volumeHigh-voltage direct current

The invention discloses an air quantity determining method of meeting cooling requirements of an extra-high voltage direct-current thawing device. The method comprises the following steps: preliminarily selecting the number of power devices which are connected with each rectifier bridge arm in series in a rated operation; calculating ideal no-load direct current voltage; calculating input side voltage; calculating voltage storage coefficients of the power devices; adjusting the number of the power devices according to the voltage storage coefficients; carrying out voltage-sharing designs of the power devices; calculating conduction losses of the power devices; calculating damping loop losses of the power devices; calculating total losses of each rectifier bridge arm in rated current; and calculating the total losses of the extra-high voltage direct-current thawing device to obtain a calorific value of the device. The method disclosed by the invention is specific and high in practicability; the number of the power devices is optimally selected under the premise of ensuring the pressure-resistant safety by calculating the voltage storage coefficients of the power devices; the cost increase and the calorific value increase caused by excessive selection are avoided; the calorific value of the device is obtained by quantitatively calculating the total losses of the devices; a design of a heat-removal system is guided; the air quantity determining method is comprehensive to consider and accurate to calculate; and an over design is avoided.

Owner:STATE GRID HUNAN ELECTRIC POWER +2

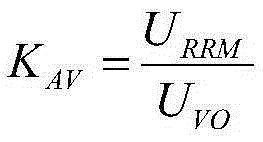

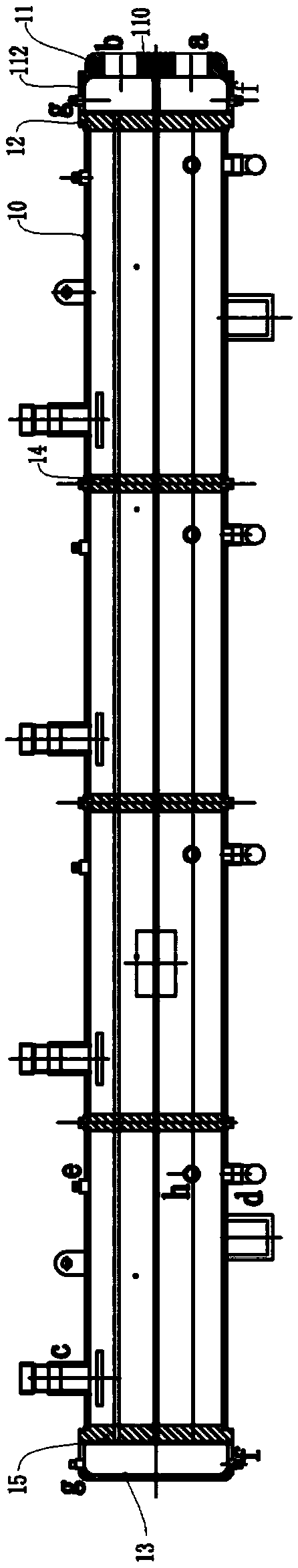

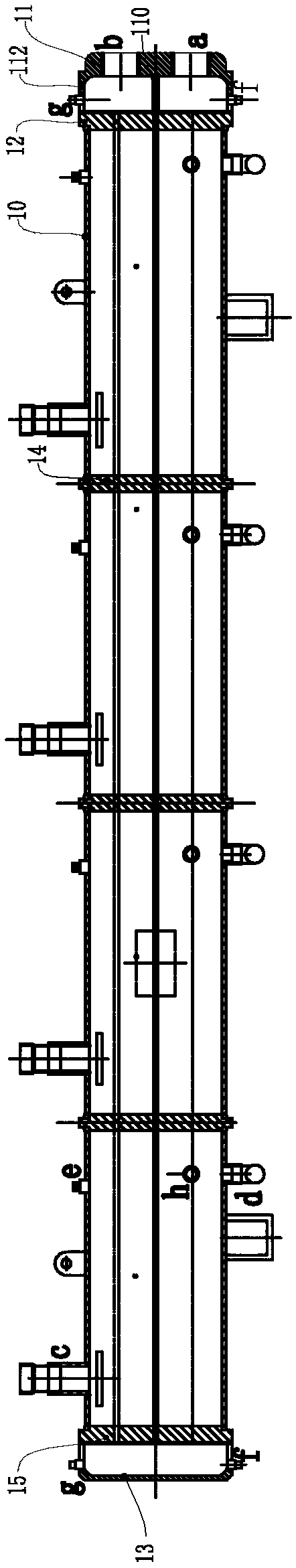

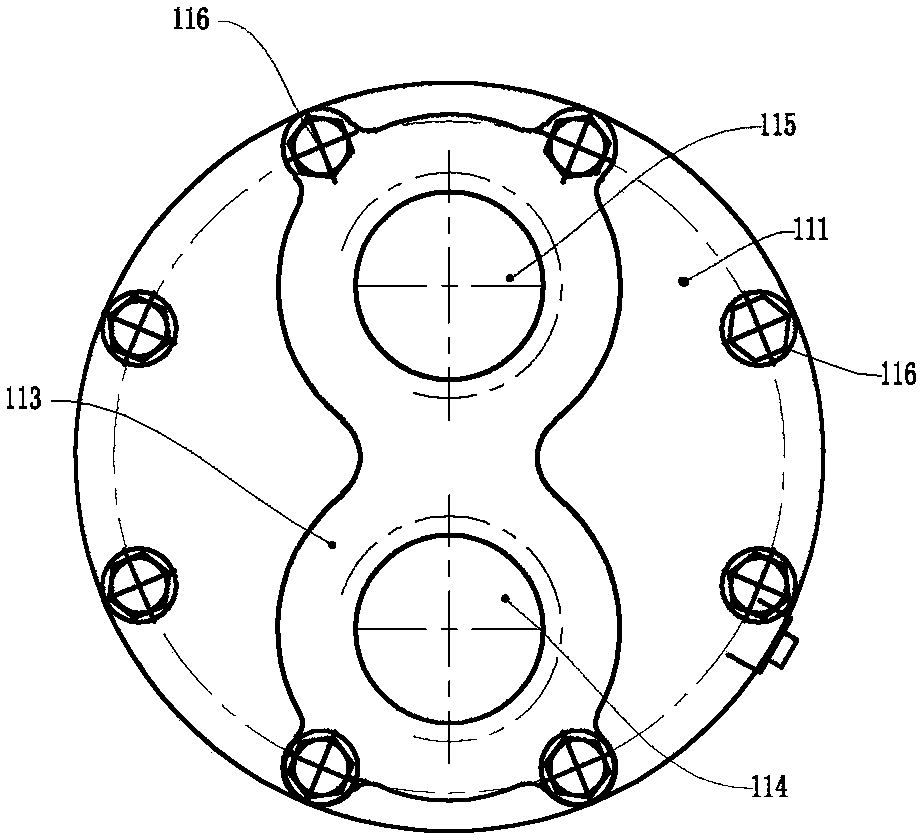

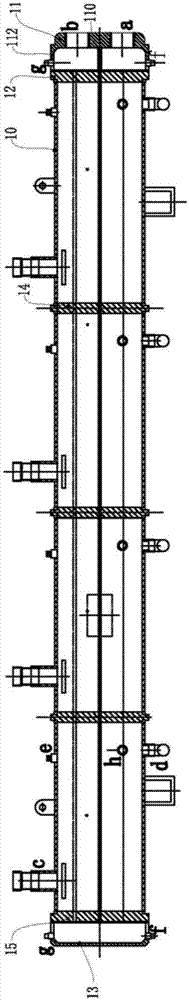

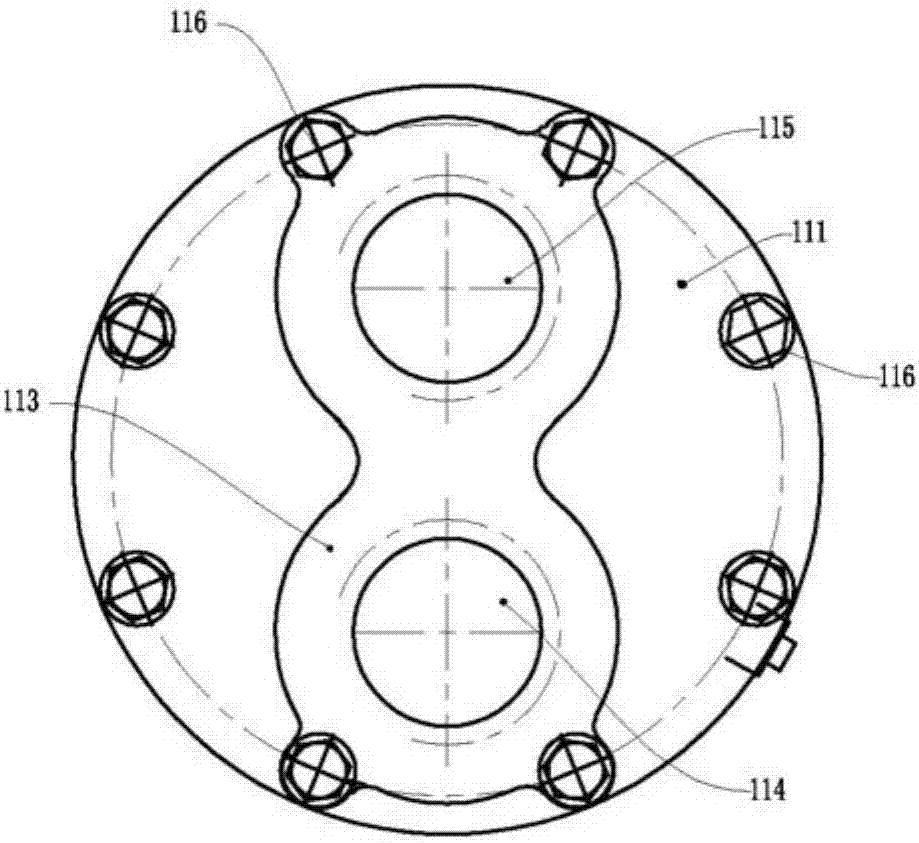

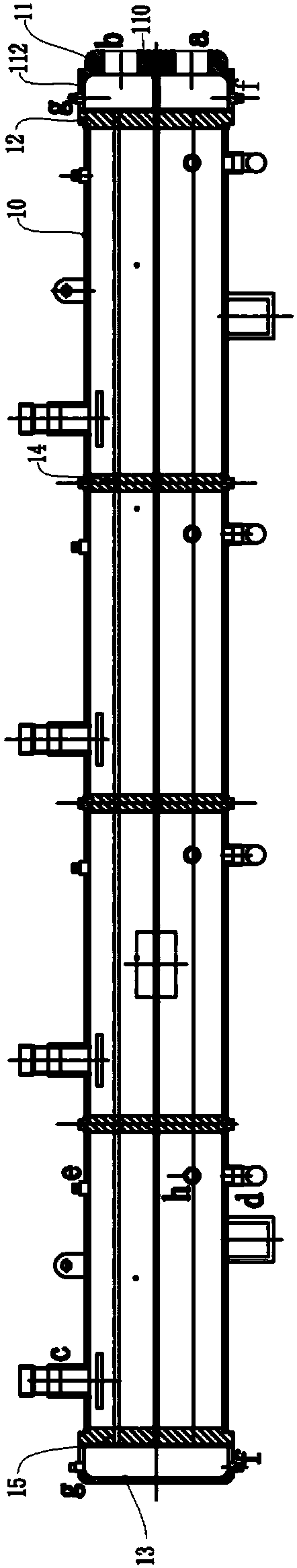

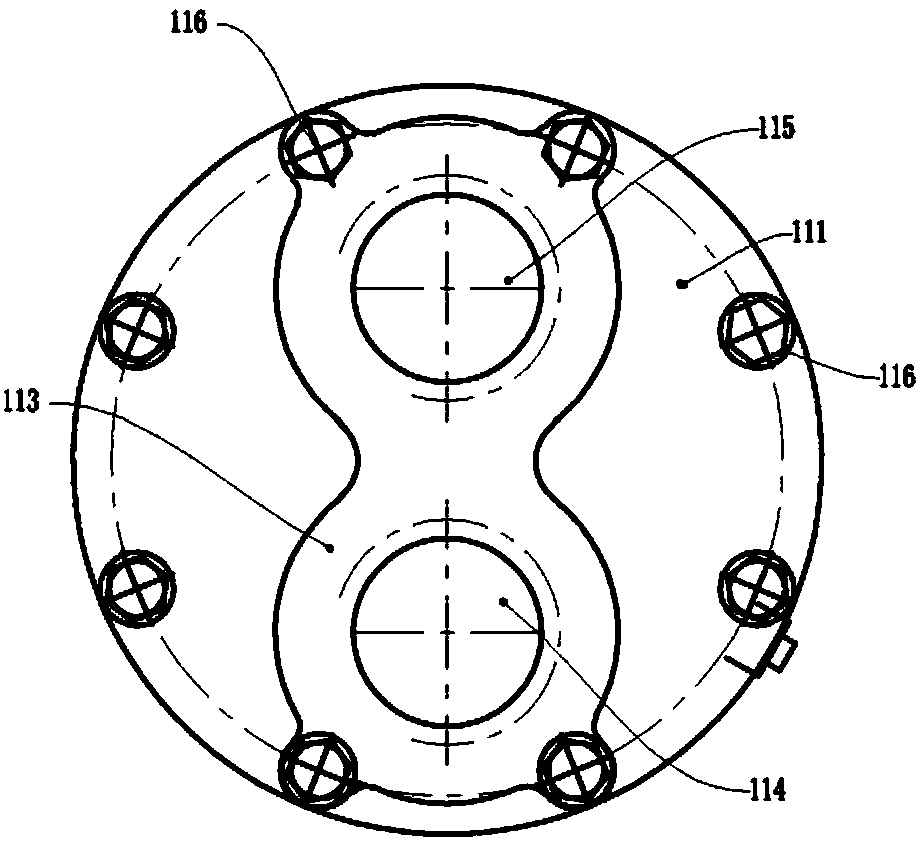

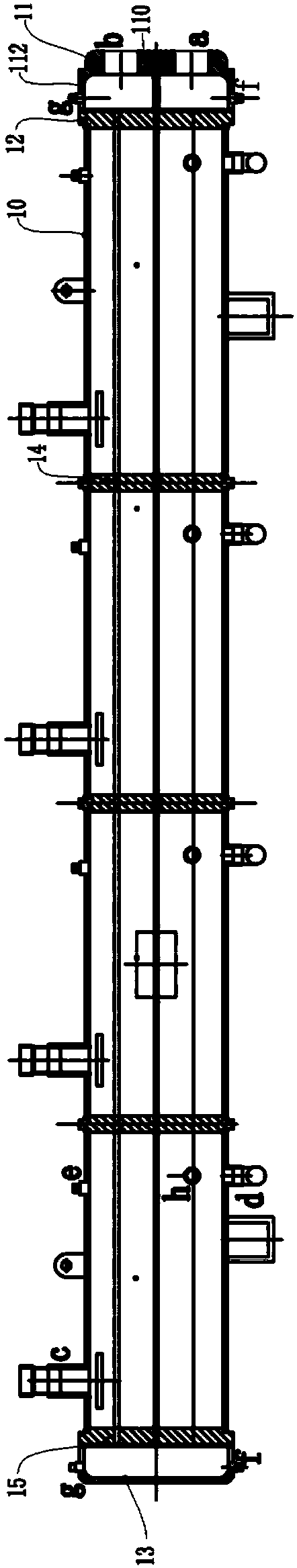

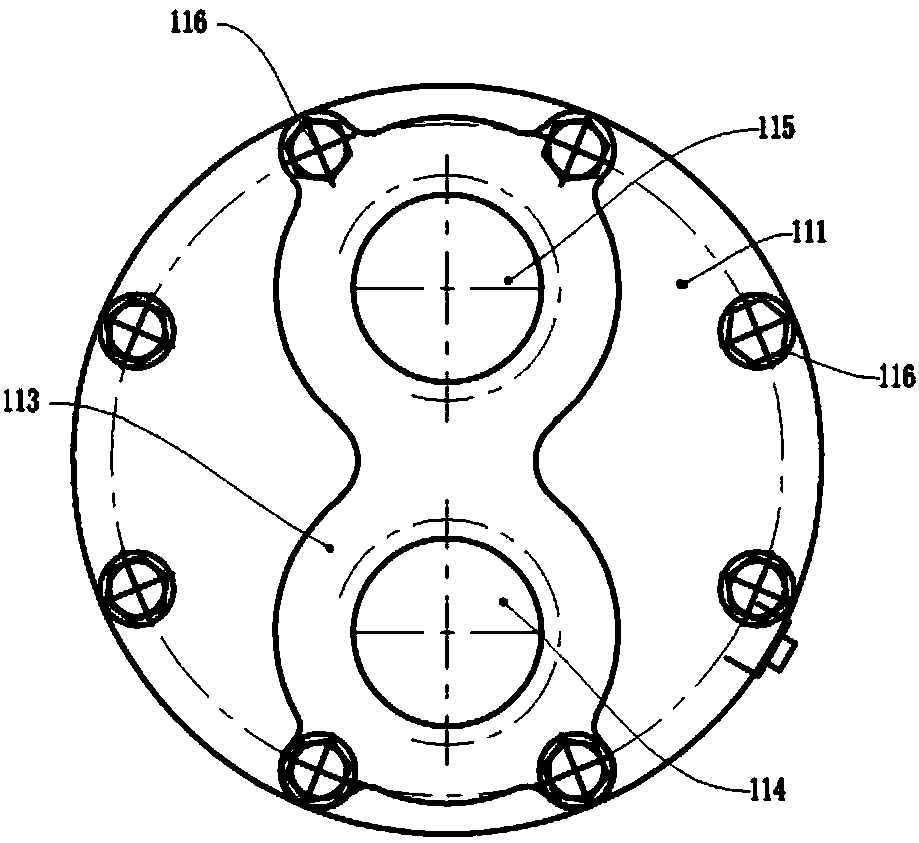

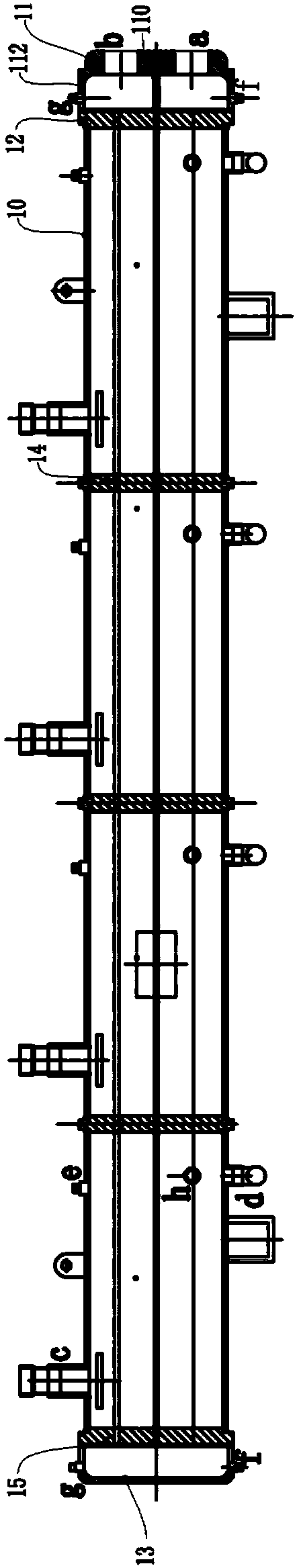

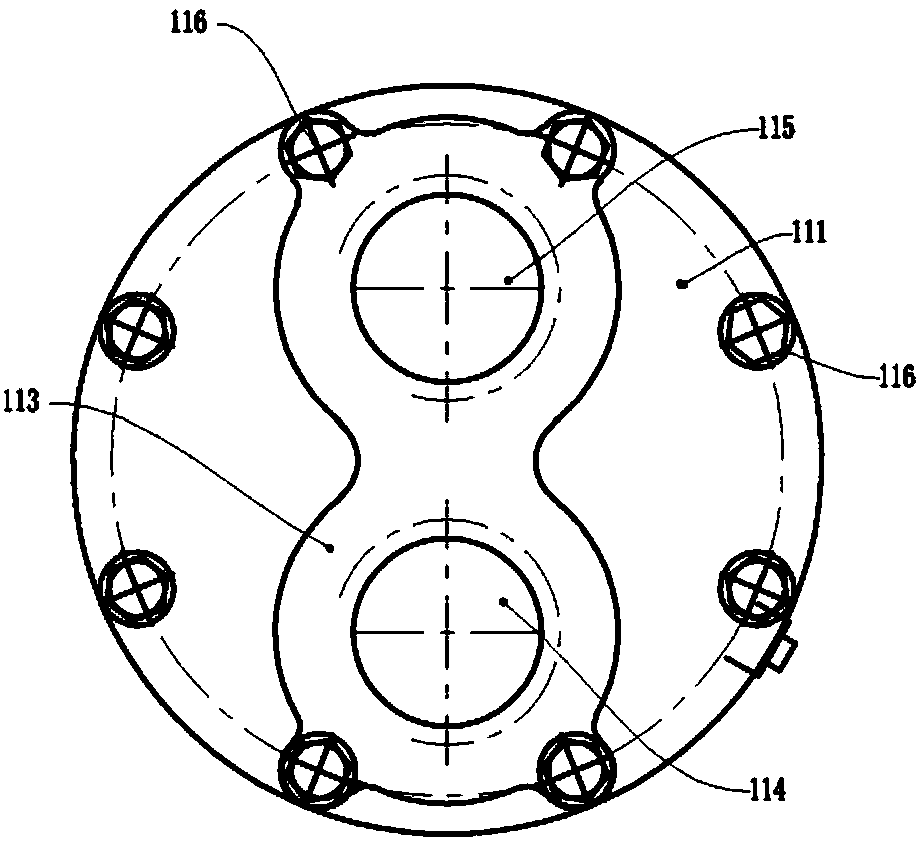

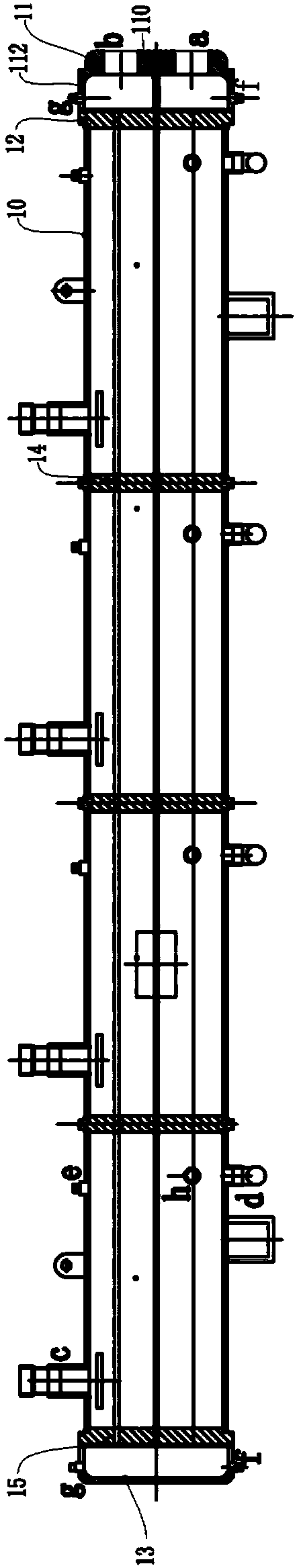

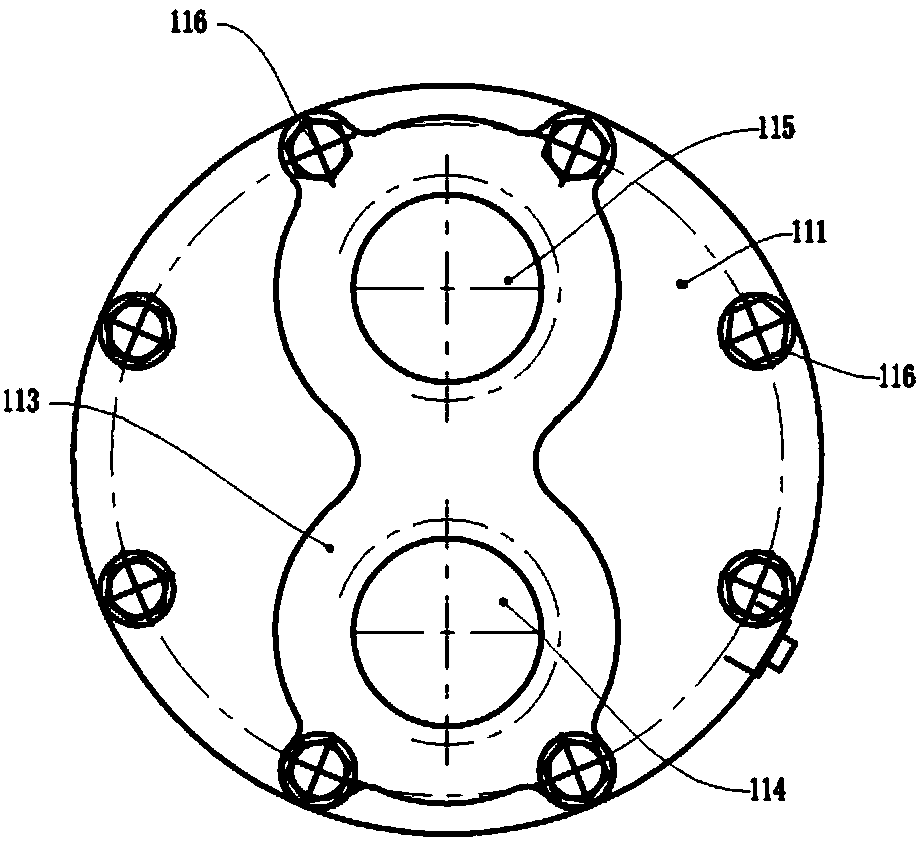

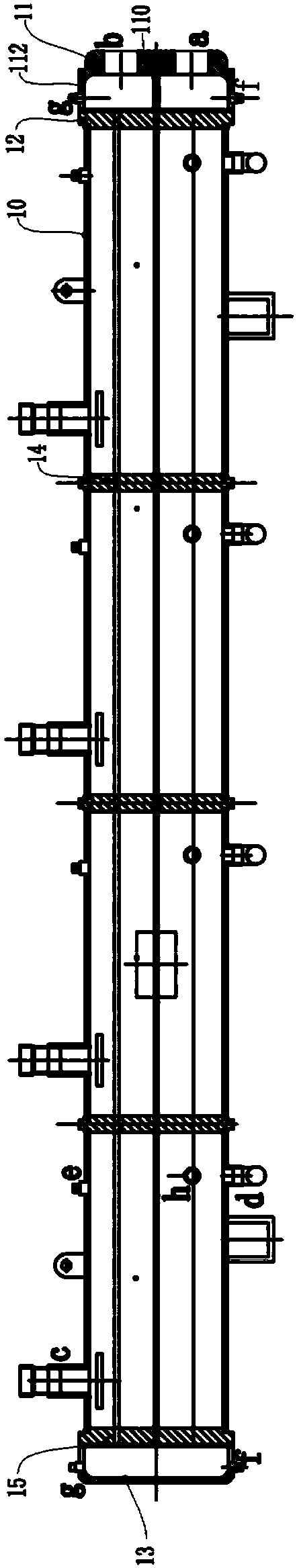

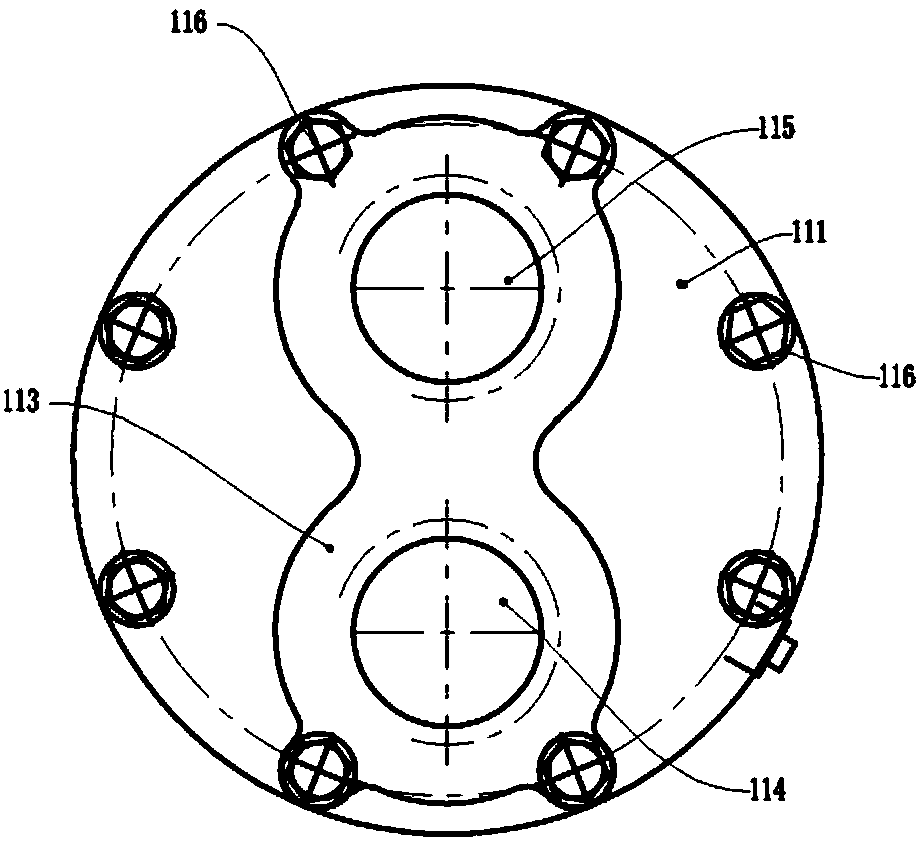

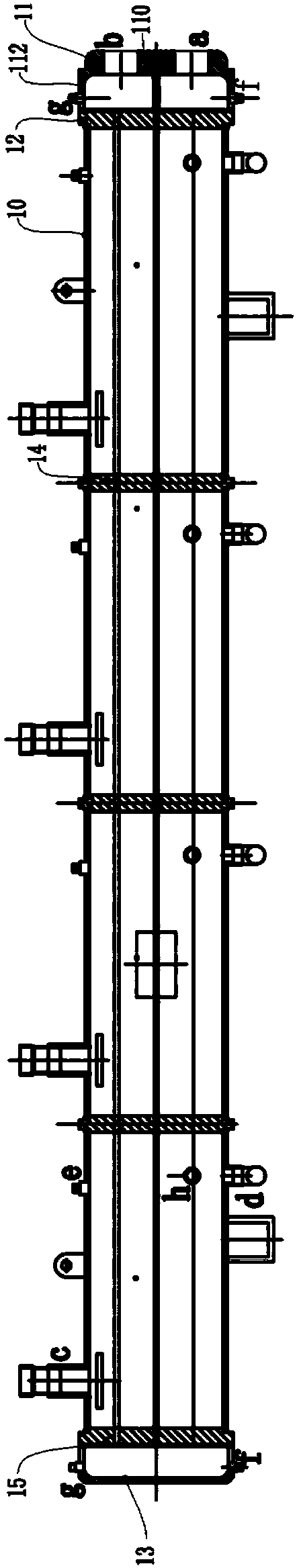

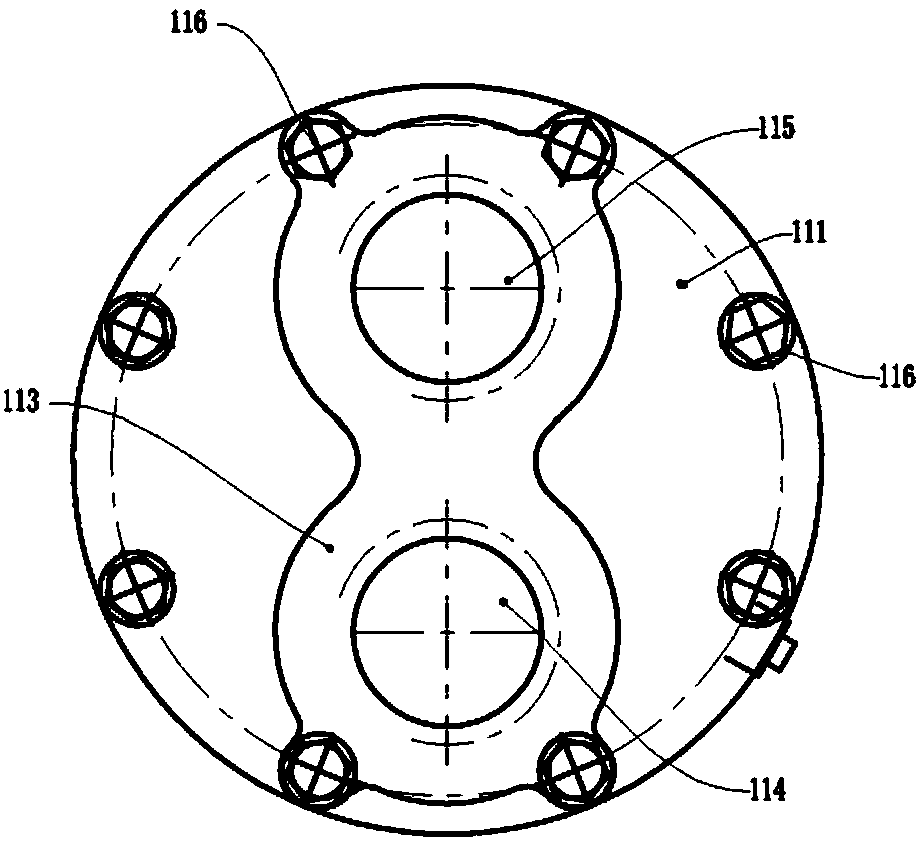

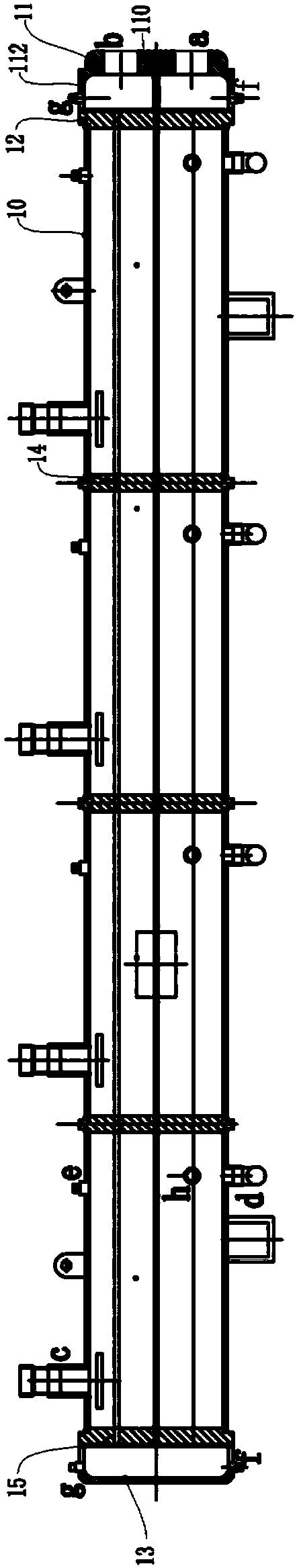

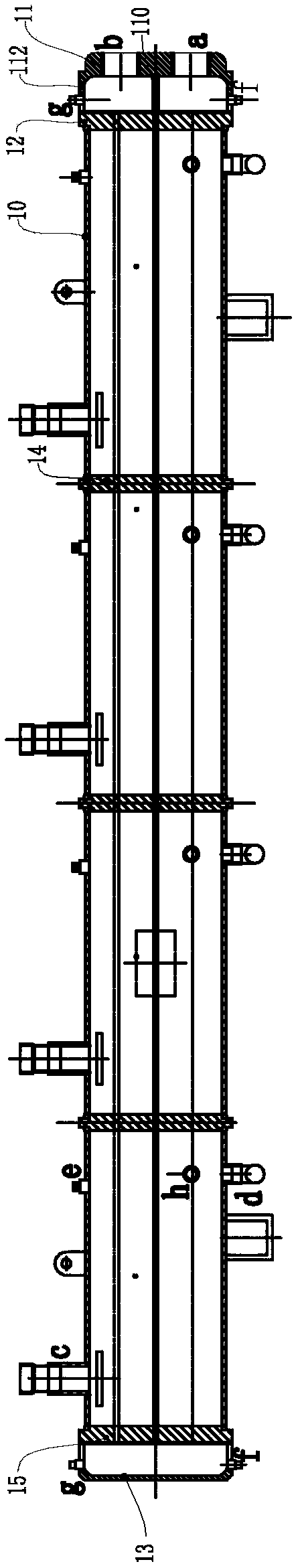

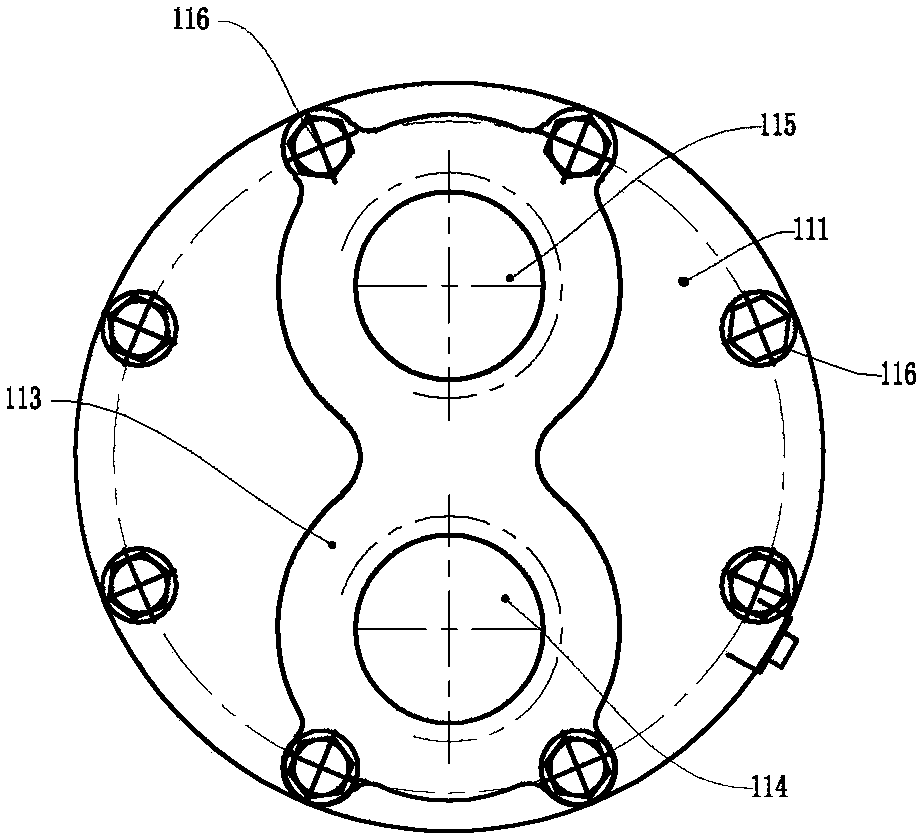

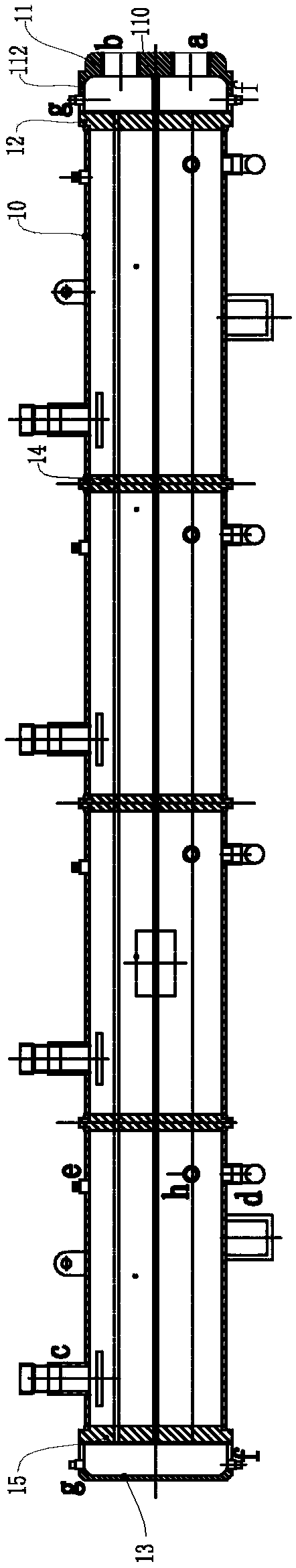

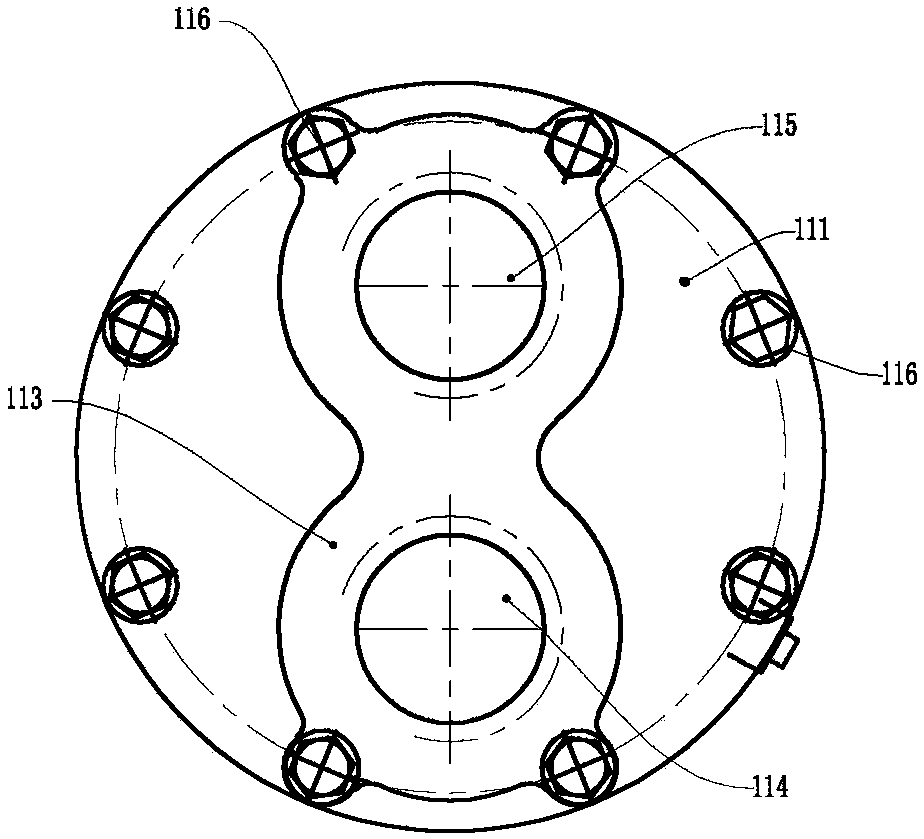

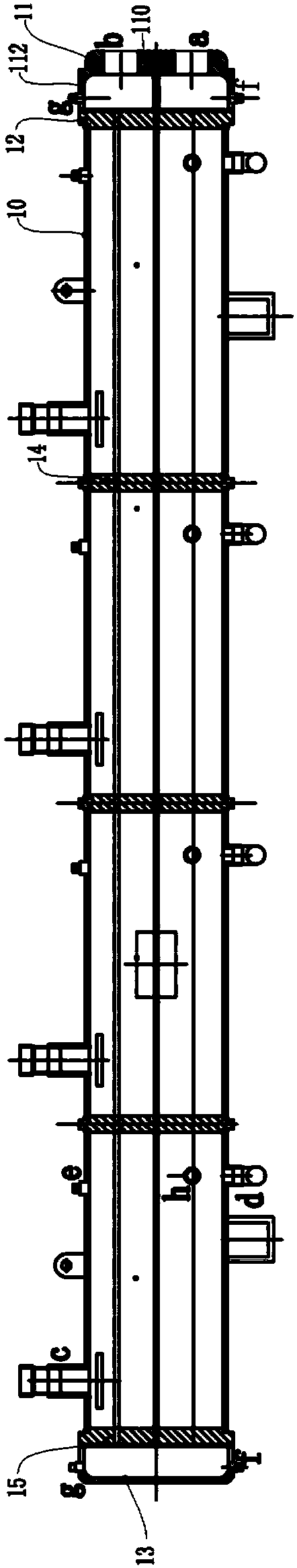

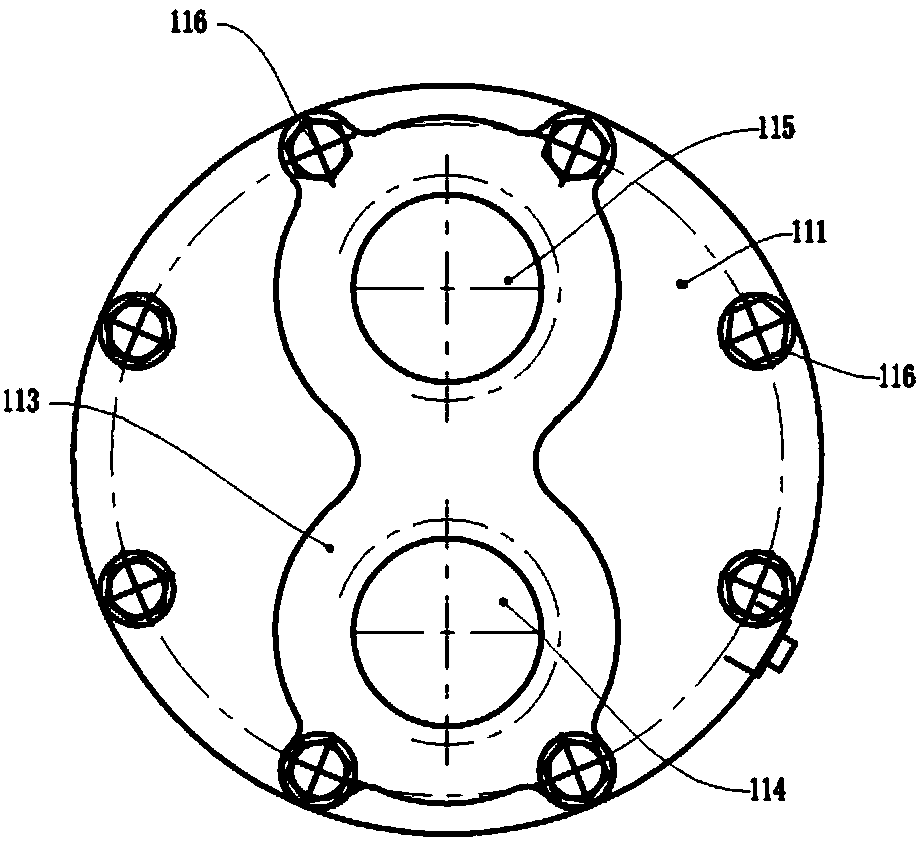

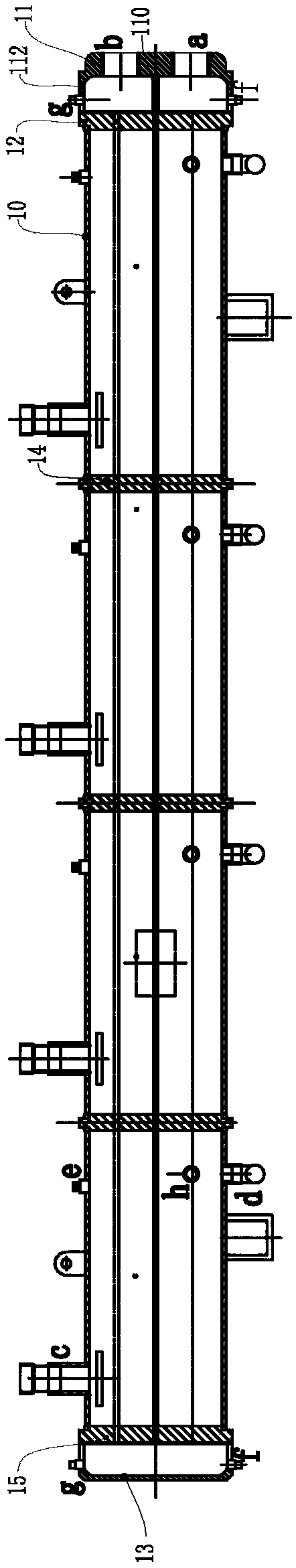

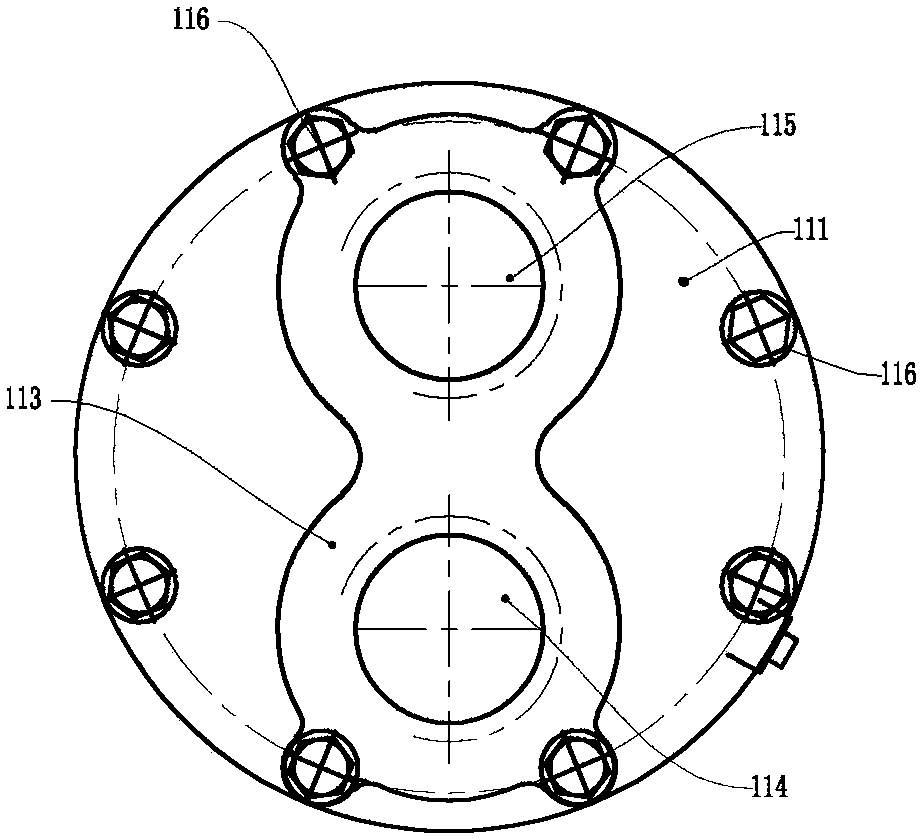

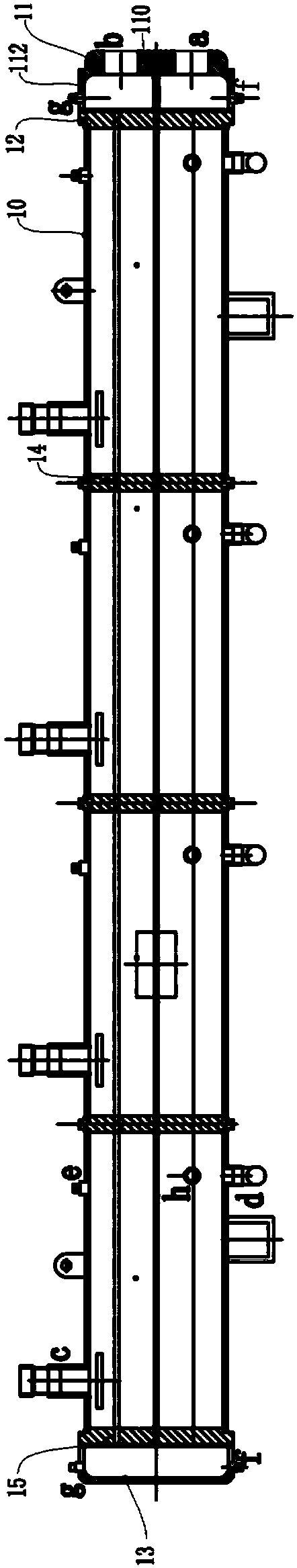

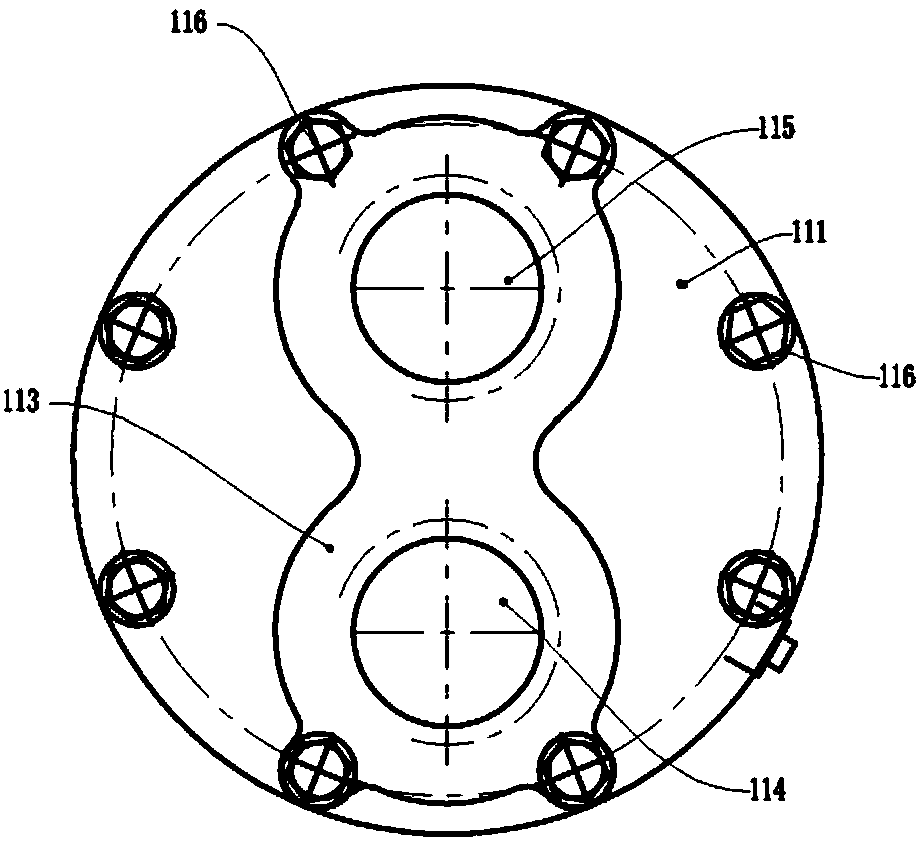

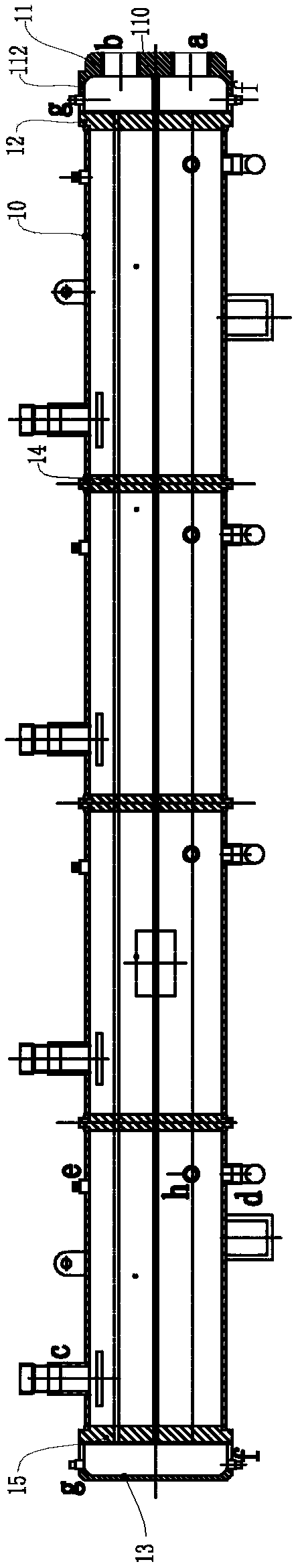

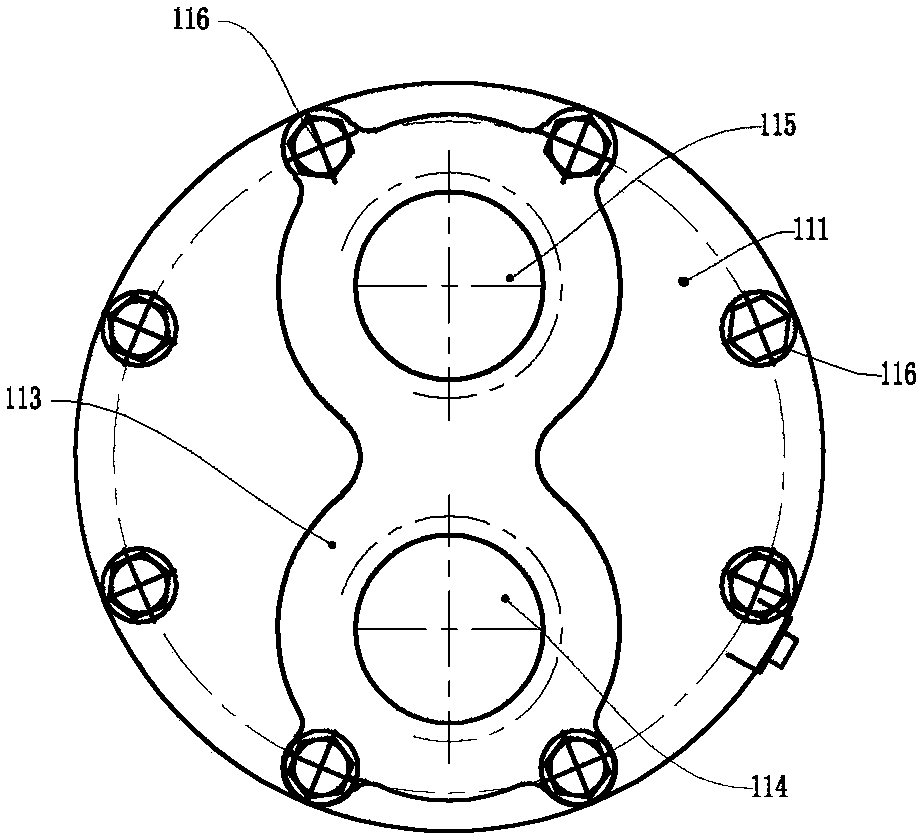

Multi-section-shell copper pipe waterway single space plate refrigeration heat exchanger

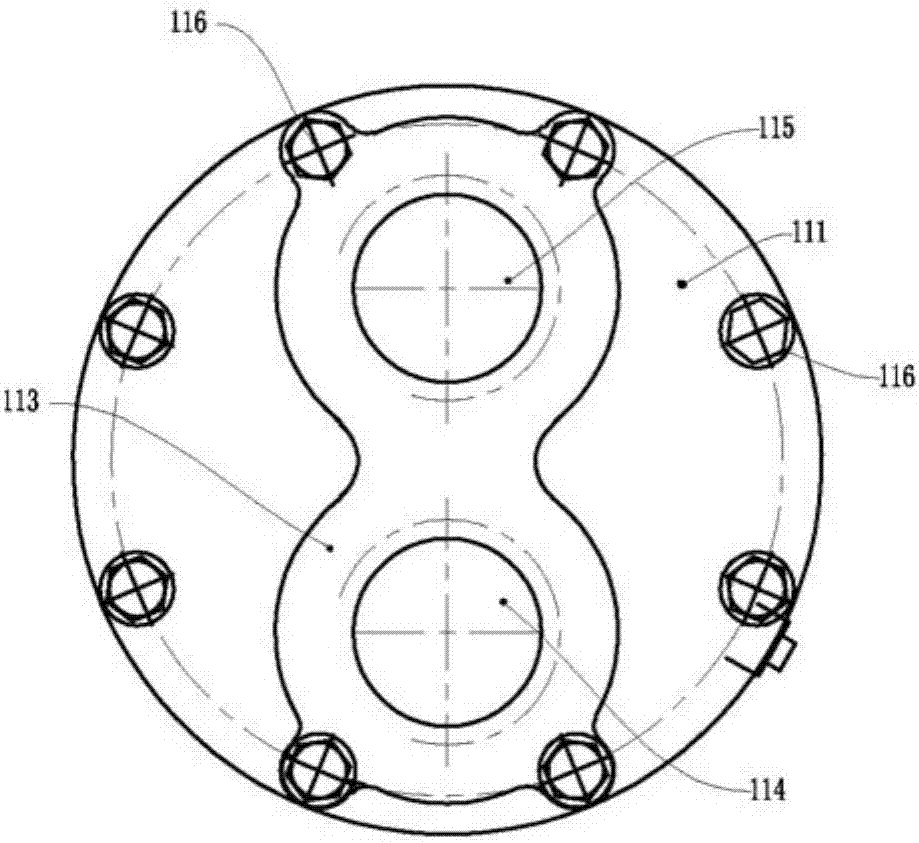

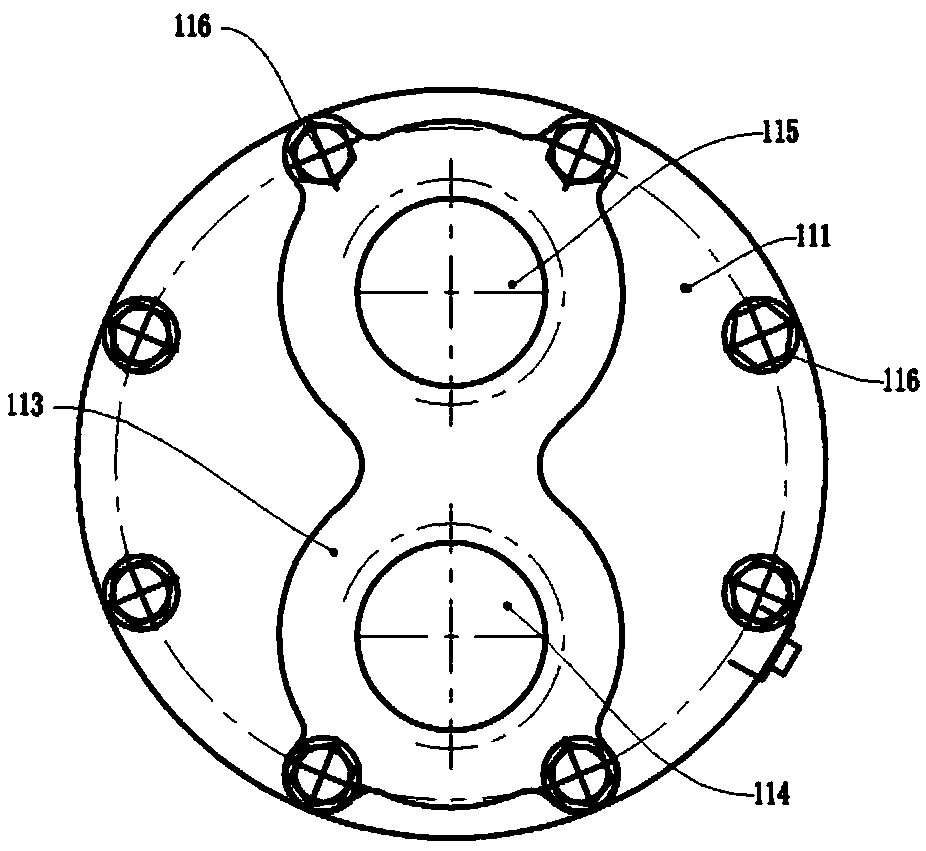

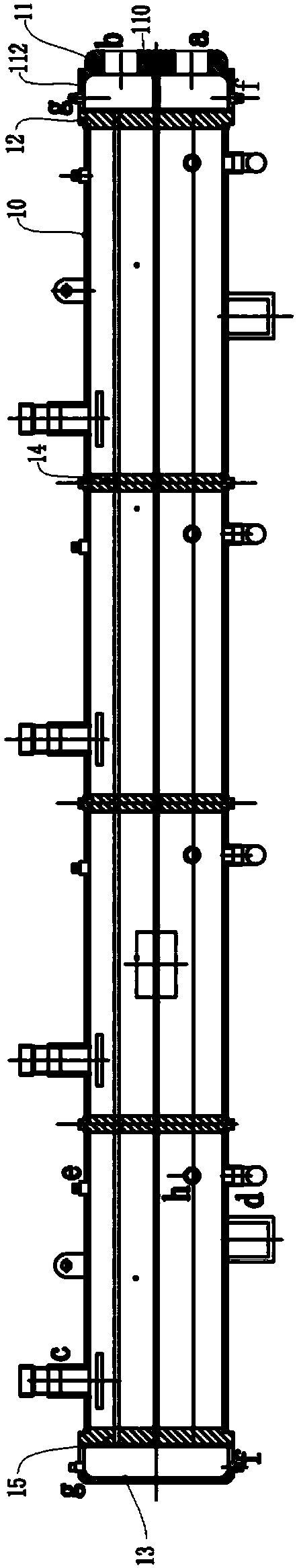

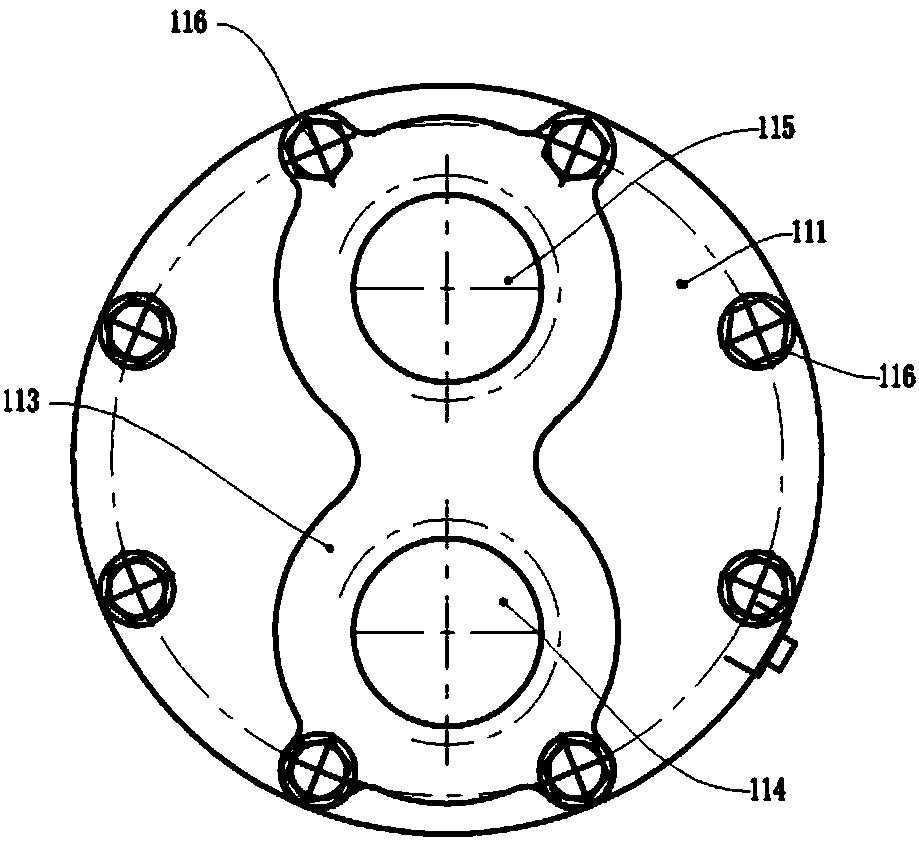

InactiveCN107957151AReduce space consumptionGuaranteed pressure safetyEvaporators/condensersHeat exchanger casingsEngineeringMulti segment

Multi-section shell copper tube waterway single partition refrigeration heat exchanger, including shell, front end cover, front partition, partition, rear end cover, rear partition and copper tube; the shell is a cylindrical cast iron shell, described in multiple sections The casings are connected end to end in series and sealed; the casing of each section is used as the casing of an evaporator of a refrigeration system; the casing of each section is provided with a refrigerant inlet, a refrigerant outlet, an exhaust port and an oil discharge port The bottom shell of the front end cover is 8-shaped; the two ends of the spacer plate are respectively welded to the ends of the two shells; the rear end cover is welded by the cylindrical shell of the outer ring and the spherical bottom cover; The rear partition is provided with a ring groove; the present invention shares the waterways of the evaporators of multiple refrigeration systems, reduces space occupation, and ensures stable operation at any time according to actual operating conditions.

Owner:梁靖玮

Cold water evaporator with multi sections of shells and copper pipe sharing single partition plate

InactiveCN108954972AReduce space consumptionGuaranteed pressure safetyEvaporators/condensersHeat exchanger casingsWater channelEngineering

The invention discloses a cold water evaporator with multi sections of shells and a copper pipe sharing a single partition plate. The cold water evaporator comprises the shells, a front end cover, a front separation plate, the partition plate, a rear end cover, a rear separation plate and the copper pipe; the shells are cylindrical cast iron shells, and the plurality of sections of shells are connected end to end in series and are sealed; each section of the shell serves as a shell of an evaporator of a refrigerating system; the shell of each section is provided with a refrigerant inlet, a refrigerant outlet, an exhaust port and an oil discharge port; bolt holes are formed in the edges of the bottom shell and the tube shell of the front end cover; the two ends of the partition plate are welded to the ends of the two sections of shells respectively; a water cavity is formed between the rear end cover and the rear separation plate; and the copper pipe is arranged inside the shell. According to the cold water evaporator, water channels of evaporators of multiple refrigeration systems are shared, so that the space occupation is reduced, and the operation under a stable working condition can be guaranteed at any time according to the actual operation condition.

Owner:梁靖玮

Multi-section pipe-shell type single partition plate cold water heat exchange

InactiveCN108106115AReduce space consumptionGuaranteed pressure safetyEvaporators/condensersCast ironEvaporator

The invention discloses a multi-section pipe-shell type single partition plate cold water heat exchanger. The cold water heat exchanger comprises a shell, a front end cover, a front separation plate,partition plates, a rear end cover, a rear separation plate and a copper pipe, wherein the shell is a cylindrical cast iron shell; a plurality of sections of the shell are connected in an end-to-end mode in series and are sealed together; and the shell of each section serves as the shell of the evaporator of a refrigerating system; the shell of each section is provided with a refrigerant inlet, arefrigerant outlet, an exhaust port and an oil discharge port; bolt holes are formed in a edge of a pipe shell and a bottom shell of the front end cover; two ends of the partition plate are welded tothe ends of the two sections of the shells correspondingly; and a water cavity is formed between the rear end cover and the rear partition plate; and an annular groove is formed in the rear partitionplate. According to the invention, water channels of the evaporators of the refrigerating systems are shared, so that space occupation is reduced; and the operation under a stable working condition can be guaranteed at any time according to the actual operation condition.

Owner:杨 萍

Multi-shell-section copper-tube-shared single-spacing-plate cold water heat exchanger

InactiveCN107990599AReduce space consumptionGuaranteed pressure safetyEvaporators/condensersHeat exchanger casingsEngineeringRefrigeration

A multi-shell-section copper-tube-shared single-spacing-plate cold water heat exchanger comprises multiple shells, a front end cover, a front partition plate, spacing plates, a back end cover, a backpartition plate and a copper tube. Each shell is a cylindrical cast iron shell. The multiple shells are connected in series in an end-to-end manner and sealed. Each shell is used as a shell of an evaporator of a refrigeration system. Each shell is provided with a refrigerant inlet, a refrigerant outlet, an exhaust opening and an oil discharging opening. The edges of a base shell and a tube shell of the front end cover are provided with bolt holes. The two ends of each spacing plate are welded to the ends of the two corresponding shells correspondingly. A water cavity is formed between the backend cover and the back partition plate. The back partition plate is provided with a ring groove. According to the multi-shell-section copper-tube-shared single-spacing-plate cold water heat exchanger, the evaporators in the multiple refrigeration systems share the water channel, occupied space is reduced, and it is guaranteed that operation is conducted under stable working conditions at any timeaccording to actual operation working conditions.

Owner:梁靖玮

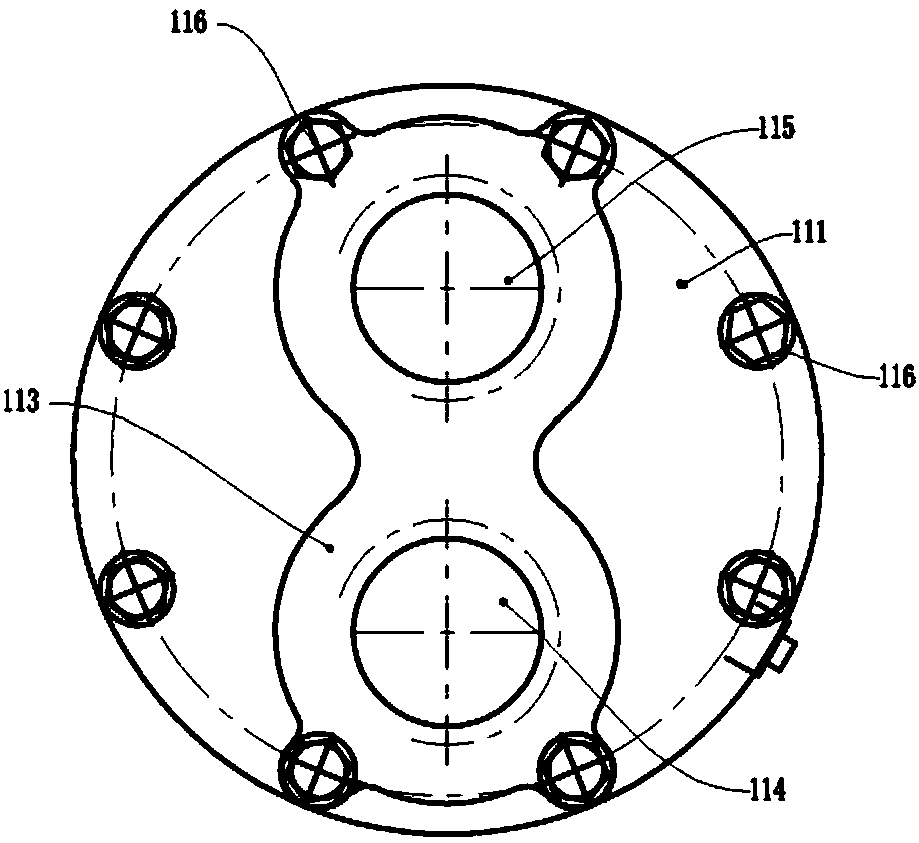

Cold water heat exchanger with plurality of sections of shells, copper pipe, waterway and double partition plates

InactiveCN108120102AReduce space consumptionGuaranteed pressure safetyEvaporators/condensersHeat exchanger casingsPlate heat exchangerWater channel

The invention discloses a cold water heat exchanger with a plurality of sections of shells, a copper pipe, a waterway and double partition plates. The heat exchanger comprises shells, a front end cover, a front separation plate, the partition plates, a rear end cover, a rear separation plate and the copper pipe, wherein the shells are cylindrical cast iron shells, and the plurality of sections ofshells are connected end to end in series and are sealed; the shell of each section serves as an outer shell of an evaporator of a refrigerating system; the shell of each section is provided with a refrigerant inlet, a refrigerant outlet, an exhaust port and an oil discharge port, wherein the bottom shell of the front end cover is of an Arabic number 8 shape, and each partition plate is composed of two flange plates which are welded to the shells on the left side and the right side correspondingly; a water cavity is formed between the rear end cover and the rear separation plate; and an annular groove is formed in the rear separation plate. According to the heat exchanger, water channels of the evaporators of a plurality of refrigeration systems are used in common, so that the space occupation is reduced; and the operation in a stable working condition can be guaranteed at any time according to the actual operation condition.

Owner:龙炽坚

Multi-section shell type single partition plate cold water evaporator

InactiveCN108106110AReduce space consumptionGuaranteed pressure safetyEvaporators/condensersHeat exchanger casingsWater channelAgricultural engineering

The invention discloses a multi-section shell type single partition plate cold water evaporator. The cold water evaporator comprises a shell, a front end cover, a front separation plate, partition plates, a rear end cover, a rear separation plate and a copper pipe, wherein the shell is a cylindrical cast iron shell; a plurality of sections of the shells are connected in an end-to-end mode in series and are sealed together; and the shell of each section serves as the shell of the evaporator of a refrigerating system; and the shell of each section is provided with a refrigerant inlet, a refrigerant outlet, an exhaust port and an oil discharge port; a bottom shell of the front end cover is a 8 shape; and the two ends of the partition plates are welded to the ends of the two sections of the shells correspondingly; and a water cavity is formed between the rear end cover and the rear partition plate; and the copper pipe is arranged in the shell. According to the invention, water channels ofthe evaporator of the refrigerating system are shared, so that space occupation is reduced; and the operation under a stable working condition can be guaranteed at any time according to the actual operation condition.

Owner:龙炽坚

Cold water heat exchanger with multiple shells and double spacing boards

InactiveCN108120088AReduce space consumptionGuaranteed pressure safetyEvaporators/condensersHeat exchanger casingsPlate heat exchangerRefrigerant

The invention relates to a cold water heat exchanger with multiple shells and double spacing boards. The cold water heat exchanger comprises shells, a front end cover, a front partition, spacing boards, a back end cover, a back partition and copper tubes, wherein the shells are cylindrical cast iron shells, and multiple shells are connected end to end in series and are sealed; each shell is used as a shell of an evaporator of a refrigerating system; a refrigerant inlet, a refrigerant outlet, an exhaust hole and an oil outlet are respectively formed in each shell; a bottom shell of the front end cover is in an eight shape; the spacing boards are two flange plates and are respectively welded with the shells on the left and right sides; a water cavity is formed between the back end cover andthe back partition; and a circular groove is formed in the back partition. According to the cold water heat exchanger, waterways of evaporators of a plurality of refrigerating systems are shared, so that the occupied space is reduced, and the operation in stable working conditions is guaranteed at any time according to actual operating conditions.

Owner:龙炽坚

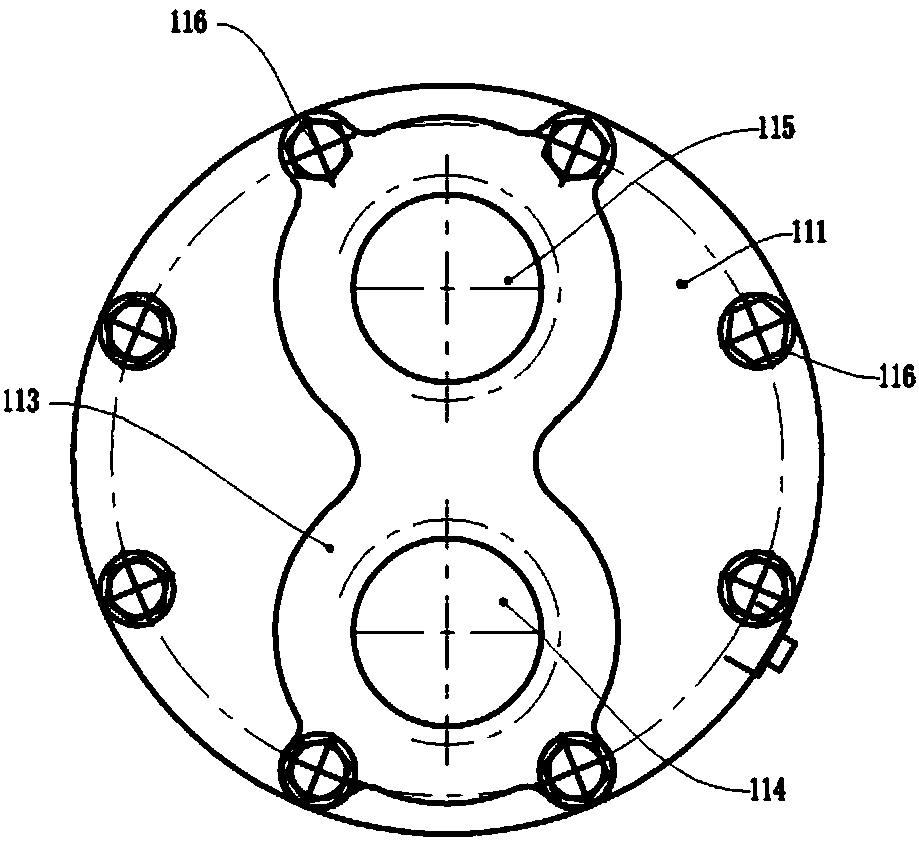

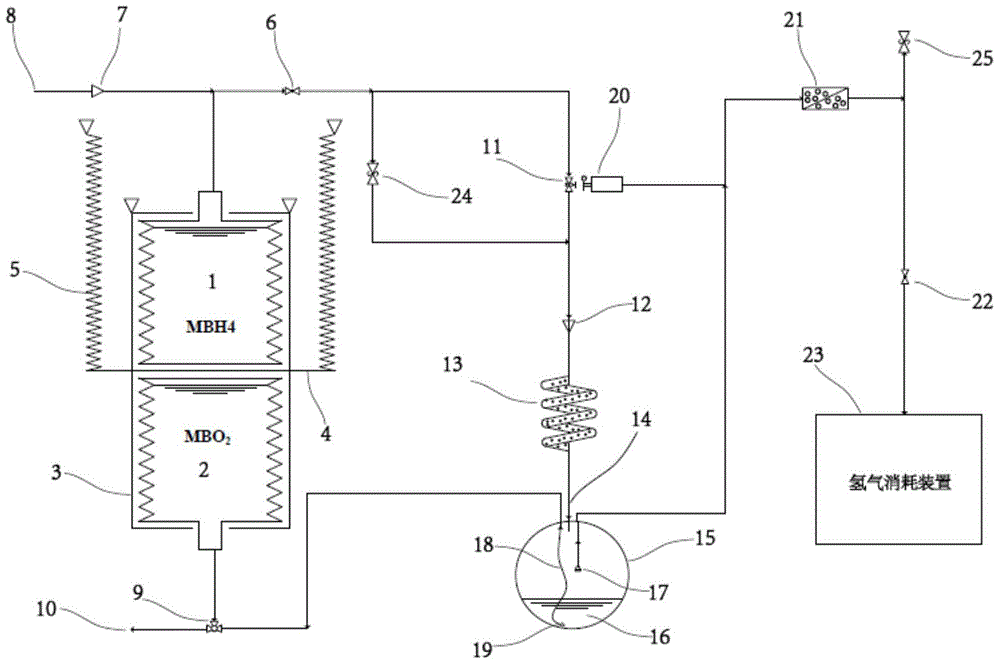

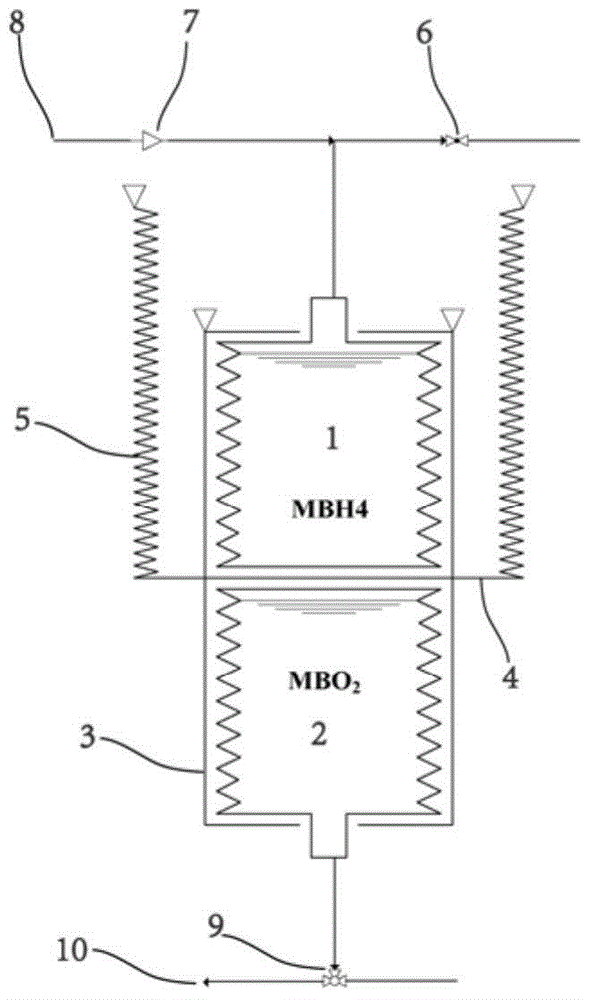

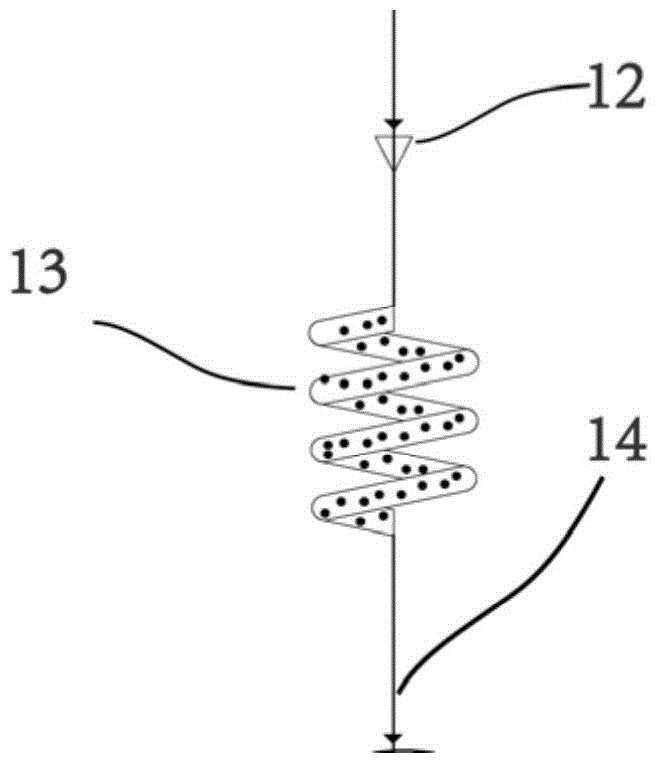

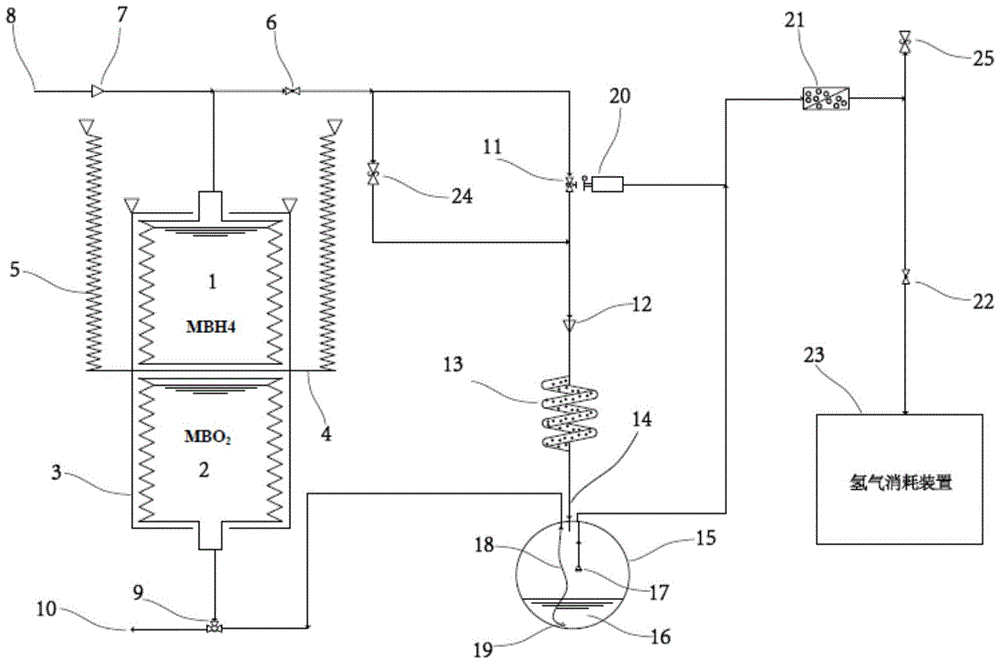

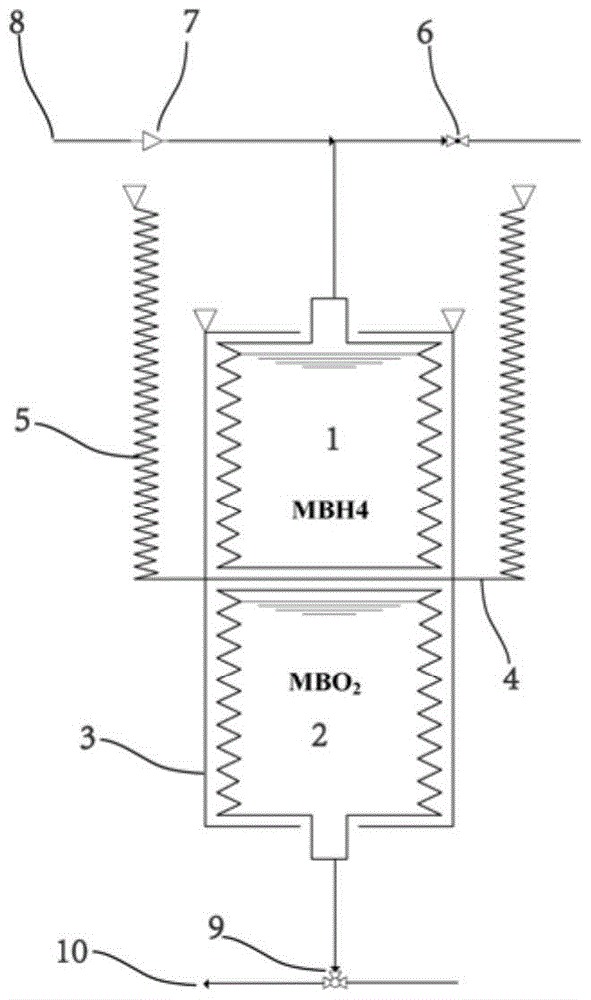

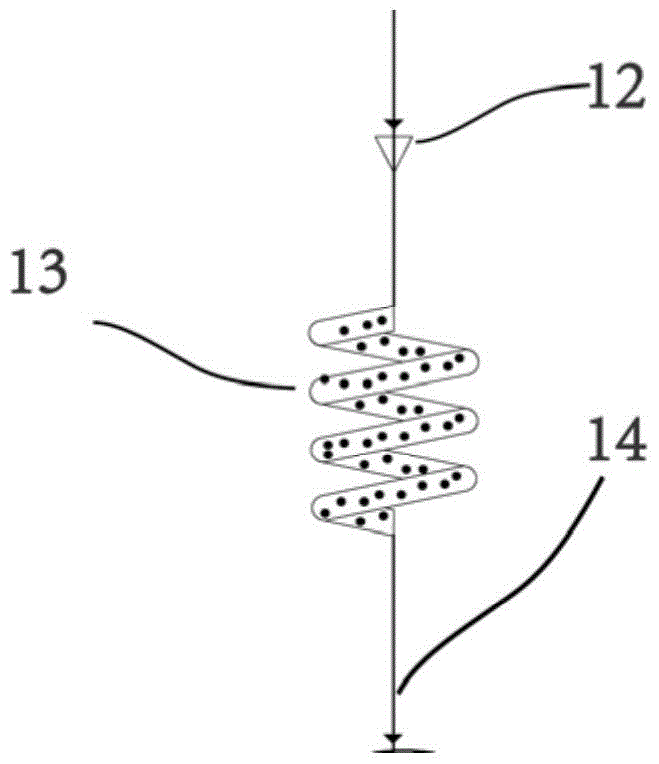

Adaptive hydrogen production system

InactiveCN104787722AAchieve emissionsRealize adaptive automatic controlHydrogen productionAutomatic controlPiston

The invention discloses an adaptive hydrogen production system. The adaptive hydrogen production system comprises a telescopic alkali metal hydroboron solution storage device, a telescopic waste liquid storage device, a reactor, a gas-liquid separator and a piston plate, wherein one end of the telescopic alkali metal hydroboron solution storage device is fixed, and the other end of the telescopic alkali metal hydroboron solution storage device is connected with one end of the piston plate; one end of the telescopic waste liquid storage device is fixed, and the other end of the telescopic waste liquid storage device is connected with the other end of the piston plate; the telescopic alkali metal hydroboron solution storage device is sequentially connected with the reactor and the gas-liquid separator by pipelines, and a liquid outlet of the gas-liquid separator is connected with the telescopic waste liquid storage device. According to the adaptive hydrogen production system, the whole system does not utilize a permeable membrane material; all the adopted components are mechanical components; the hydrogen production reaction speed adapts to automatic control according to the change of hydrogen consumption; the operation of the system has a direction independence characteristic; furthermore, reaction wastes can be automatically recovered, a fuel adding process and a waste liquid discharging process are simple and convenient, and the pressure safety of the system at any state can be ensured.

Owner:XI AN JIAOTONG UNIV +1

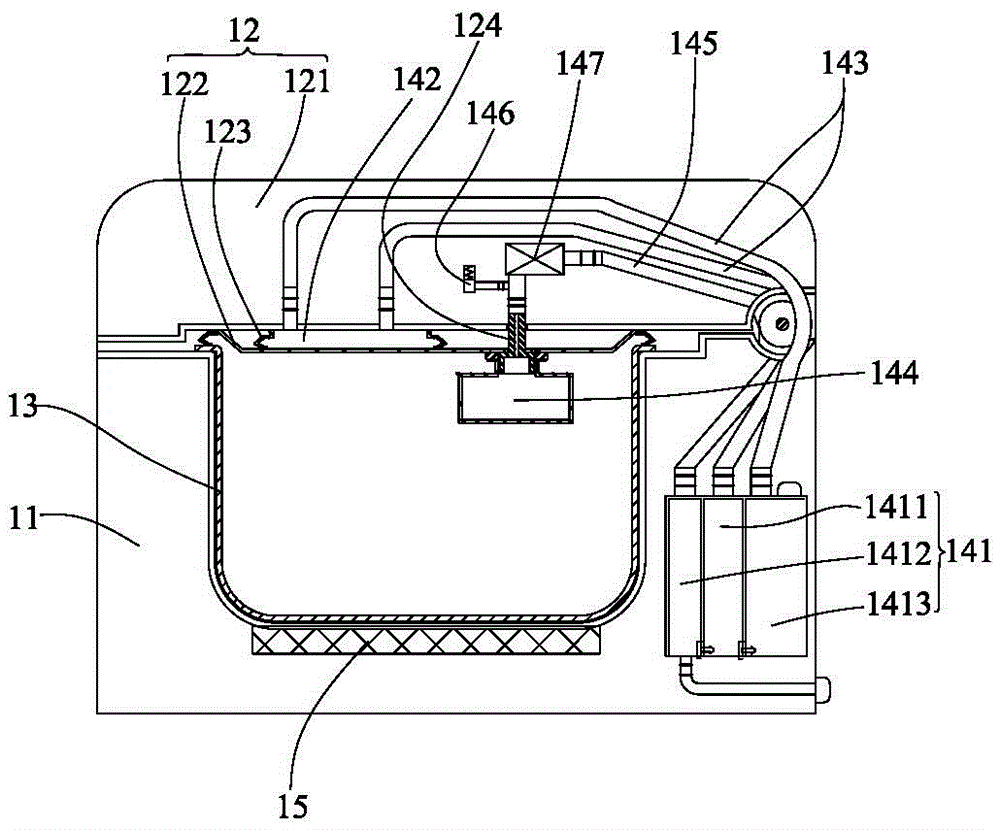

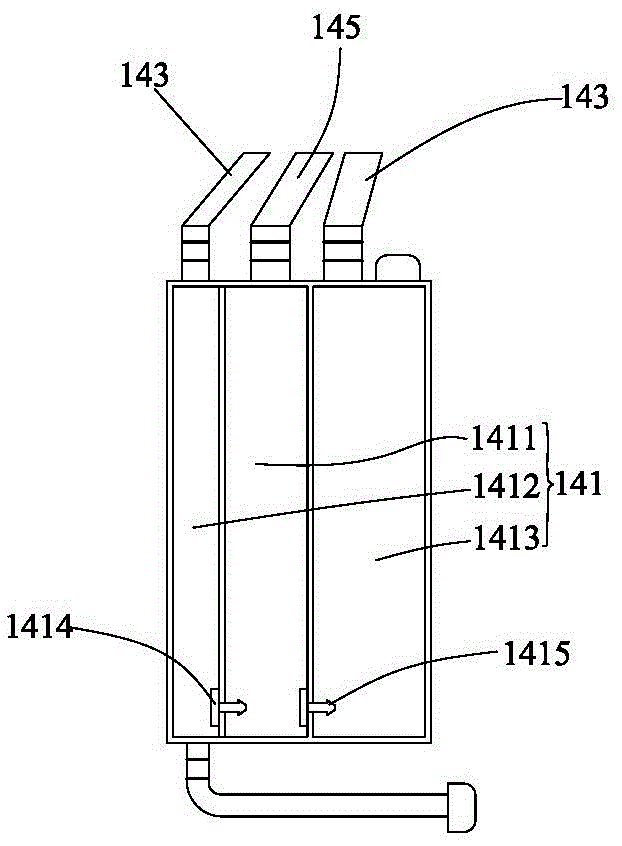

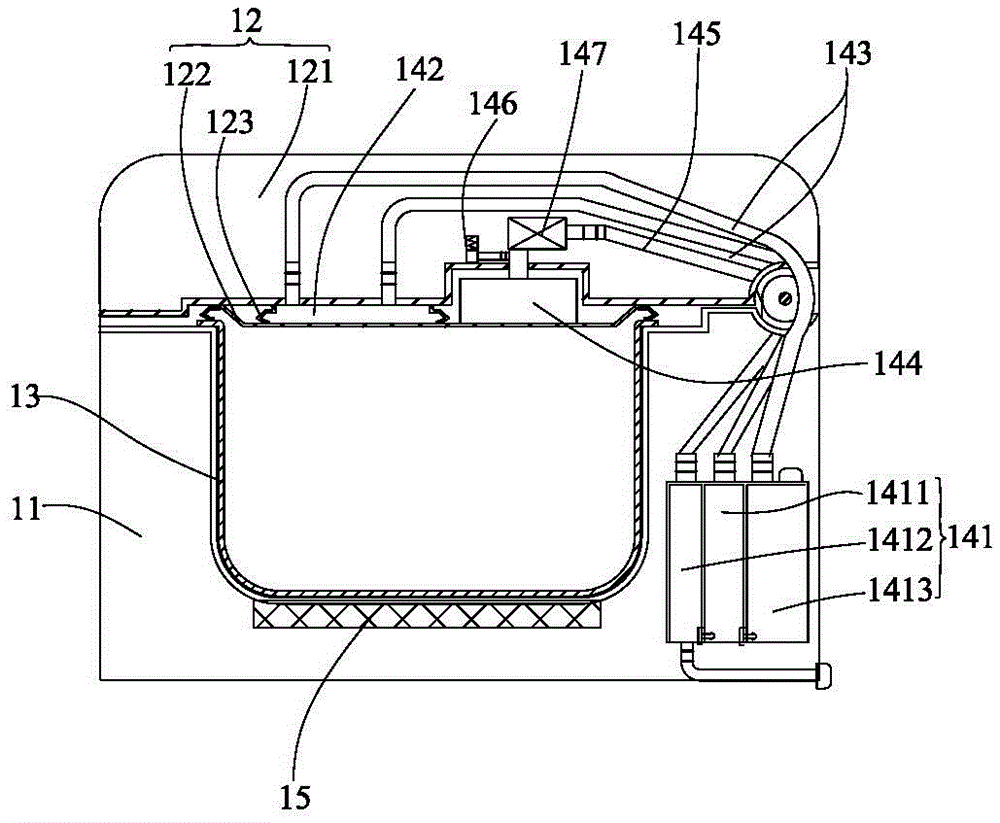

A rapid cooling pressure cooking device

The invention relates to a rapid cooling pressure cooking device, which comprises a pot body, a pot cover, an inner container, a cooling device and a heating device located at the bottom of the pot body, the inner container is placed in the pot body, the pot cover includes an outer cover and an inner cover, and the pot The lid is fastened to seal the inner tank, and the cooling device includes a water tank filled with cooling water, a cooling cavity, and a circulating water pipe connecting the water tank and the cooling cavity. The cooling device also includes a steam pressure chamber, the steam pressure chamber is installed on the inner cover, the steam pressure chamber is provided with an exhaust pipe connected to the water tank, the heating device heats the inner tank, the high temperature steam in the inner tank heats the steam pressure chamber, and the steam pressure The water in the chamber is heated to form pressure steam, and the pressure steam enters the water tank through the exhaust pipe, and the cooling water in the water tank is under pressure and enters the cooling chamber through the circulating water pipe to circulate and cool the steam in the inner tank. The steam in the inner tank is directly used to heat the steam pressure chamber to form the power to drive the water in the water tank, which not only saves the cost of the water pump, but also reduces the driving power of the water pump.

Owner:JOYOUNG CO LTD

An Adaptive Hydrogen Production System

InactiveCN104787722BAchieve emissionsRealize adaptive automatic controlHydrogen productionAutomatic controlMechanical components

The invention discloses an adaptive hydrogen production system. The adaptive hydrogen production system comprises a telescopic alkali metal hydroboron solution storage device, a telescopic waste liquid storage device, a reactor, a gas-liquid separator and a piston plate, wherein one end of the telescopic alkali metal hydroboron solution storage device is fixed, and the other end of the telescopic alkali metal hydroboron solution storage device is connected with one end of the piston plate; one end of the telescopic waste liquid storage device is fixed, and the other end of the telescopic waste liquid storage device is connected with the other end of the piston plate; the telescopic alkali metal hydroboron solution storage device is sequentially connected with the reactor and the gas-liquid separator by pipelines, and a liquid outlet of the gas-liquid separator is connected with the telescopic waste liquid storage device. According to the adaptive hydrogen production system, the whole system does not utilize a permeable membrane material; all the adopted components are mechanical components; the hydrogen production reaction speed adapts to automatic control according to the change of hydrogen consumption; the operation of the system has a direction independence characteristic; furthermore, reaction wastes can be automatically recovered, a fuel adding process and a waste liquid discharging process are simple and convenient, and the pressure safety of the system at any state can be ensured.

Owner:XI AN JIAOTONG UNIV +1

Determination method of air volume to meet cooling requirements of UHV DC ice-melting device

ActiveCN105305354BDesign effective guidanceClear methodOverhead installationSpecial data processing applicationsHigh-voltage direct currentConduction loss

The invention discloses a method for determining the air volume that satisfies the cooling requirements of an UHV DC ice-melting device, which includes preliminary selection of the number of power devices connected in series with each rectifier bridge arm during rated operation; calculation of the ideal no-load DC voltage; and calculation of the input side voltage; Calculate the voltage reserve coefficient of the power device; adjust the number of power devices according to the voltage reserve coefficient; carry out the voltage equalization design of the power device; calculate the conduction loss of the power device; calculate the damping circuit loss of the power device; calculate the rated current of each rectifier bridge arm The total loss; calculate the total loss of the UHV DC ice-melting device to obtain the calorific value of the device. The method of the present invention is clear and practical. By calculating the voltage reserve coefficient of the power device, the number of power devices is optimally selected under the premise of ensuring the safety of the withstand voltage, so as to avoid the increase in cost and the increase in calorific value caused by excessive selection; through quantitative calculation of the device The total loss can be used to obtain the calorific value of the device, guide the design of the cooling system, consider comprehensively, calculate accurately, and avoid over-design.

Owner:STATE GRID HUNAN ELECTRIC POWER +2

Multi-housing-section, copper-pipe-water-channel and single-separating-plate type cold water heat exchanger

InactiveCN108106134AReduce space consumptionGuaranteed pressure safetyEvaporators/condensersHeat exchanger casingsControl engineeringEngineering

A multi-housing-section, copper-pipe-water-channel and single-separating-plate type cold water heat exchanger comprises housings, a front end cover, a front separating plate, a separating plate, a rear end cover, a rear separating plate and a copper pipe, wherein the housings are cylindrical cast iron housings; a plurality of housings are connected in series in an end-to-end manner and are sealed;each housing is treated as the housing of an evaporator of a refrigerating system, and each housing is provided with a refrigerant inlet, a refrigerant outlet, an air exhausting port and an air outlet; a bottom housing of the front end cover is 8-shaped; two ends of the separating plate are correspondingly welded to the end parts of two housings; a water chamber is formed between the rear end cover and the rear separating plate; an annular groove is formed in the rear separating plate. According to the multi-sectional-housing, copper-pipe-water-channel and single-separating-plate type cold water heat exchanger, water channels of the evaporators of a plurality of refrigerating systems are shared, so that the occupied space is reduced; and the stable working condition is ensured for operation based on the actual operation condition.

Owner:龙炽坚

Multi-shell copper pipe waterway single-spacing-plate water-cooled evaporator

InactiveCN108106127AReduce space consumptionGuaranteed pressure safetyEvaporators/condensersHeat exchanger casingsEngineeringRefrigerant

A multi-shell copper pipe waterway single-spacing-plate water-cooled evaporator comprises shells, a front end cover, a front partition plate, a spacing plate, a rear end cover, a rear partition plateand a copper pipe; the shells are cylindrical cast iron shells, the multiple sections of shells are connected end to end in series and sealed; each shell serves as a shell of an evaporator of a refrigeration system and is provided with a refrigerant inlet, a refrigerant outlet, a gas outlet and an oil outlet; a bottom shell of the front end cover is in the shape like the Arabic number eight; the two ends of the spacing plate are welded to the ends of two sections of shells correspondingly; a water cavity is formed between the rear end cover and the rear partition plate; and the copper pipe isarranged in the shells. According to the multi-shell copper pipe waterway single-spacing-plate water-cooled evaporator, the evaporators of the multiple refrigeration systems share the same waterway, the occupied space is decreased, and the effect that operation is conducted under the stable working condition is ensured according to the actual operation working condition at any time.

Owner:龙炽坚

Refrigeration heat exchanger with multi sections of shells and double partition plates

InactiveCN108120073AReduce space consumptionGuaranteed pressure safetyEvaporators/condensersIndirect heat exchangersRefrigerantCast iron

The invention discloses a refrigeration heat exchanger with multi sections of shells and double partition plates. The refrigeration heat exchanger comprises the shells, a front end cover, a front separation plate, the partition plates, a rear end cover, a rear separation plate and a copper pipe; the shells are cylindrical cast iron shells, and the multiple sections of the shells are connected endto end in series and are sealed together; the shell of each section serves as a shell of an evaporator of a refrigerating system; the shell of each section is provided with a refrigerant inlet, a refrigerant outlet, an exhaust port and an oil discharge port; and a bottom shell of the front end cover is 8-shaped; the partition plates are two flange plates and are welded to the outer shell on the left side and the right side; the rear end cover is formed by welding a cylindrical shell of an outer ring and a spherical bottom cover; and an annular groove is formed in the rear separation plate. According to the refrigeration heat exchanger, water channels of the evaporators of the multiple refrigeration systems are shared, so that space occupation is reduced, and operation under a stable working condition can be guaranteed at any time according to the actual operation condition.

Owner:龙炽坚

Multi-section shell copper pipe water way single-spacing-plate refrigeration evaporator

InactiveCN108106149AReduce space consumptionGuaranteed pressure safetyEvaporators/condensersHeat exchanger casingsPipe waterEngineering

The invention discloses a multi-section shell copper pipe water way single-spacing-plate refrigeration evaporator. The multi-section shell copper pipe water way single-spacing-plate refrigeration evaporator comprises shells, a front end cover, a front separation plate, a spacing plate, a back end cover, a back separation plate and copper pipes; the shells are cylindrical cast iron shells; multiplesections of the shells are serially connected end to end and sealed; each section of the shell serves as a shell of an evaporator of a refrigeration system; each section of the shell serves as a shell of an evaporator of a refrigeration system; each section of the shell is provided with a refrigerant inlet, a refrigerant outlet, an exhaust port and an oil discharge port; a bottom shell of the front end cover is 8-shaped; the two ends of the spacing plate are respectively welded at the end parts of two sections of the shells; the back end cover is welded by a cylindrical shell on the outer ring and a spherical bottom cover; and the copper pipes are in the shells. Water ways of evaporators of multiple refrigeration systems are shared to reduce occupied space; and operation under stable working conditions is guaranteed according to actual operation working conditions at any time.

Owner:梁靖玮

Copper pipe water channel double-space-plate refrigeration evaporator with multiple outer shell sections

InactiveCN108120057AReduce space consumptionGuaranteed pressure safetyEvaporators/condensersHeat exchanger casingsPipe waterWater channel

A copper pipe water channel double-space-plate refrigeration evaporator with multiple outer shell sections comprises an outer shell, a front end cover, a front space plate, space plates, a rear end cover, a rear space plate and a copper pipe. The outer shell is a cylindrical cast iron outer shell. The multiple outer shell sections are connected end to end in series and sealed. Each outer shell section is used as an outer shell body of an evaporator body of a refrigeration system and provided with a refrigerant inlet, a refrigerant outlet, an exhaust port and an oil discharging outlet. A bottomshell of the front end cover is shaped like the number '8'. Two flange plates are used as the space plates, and the space plates are welded to the outer shell sections located on the left side and the right side correspondingly. The rear end cover is formed by welding a cylindrical shell on the outer ring with a spherical-surface-shaped bottom cover. The copper pipe is arranged in the outer shell. The evaporator bodies of multiple refrigeration systems share a water channel, the occupied space is reduced, and stable operation under the working conditions is ensured at any time according to the actual operation working conditions.

Owner:龙炽坚

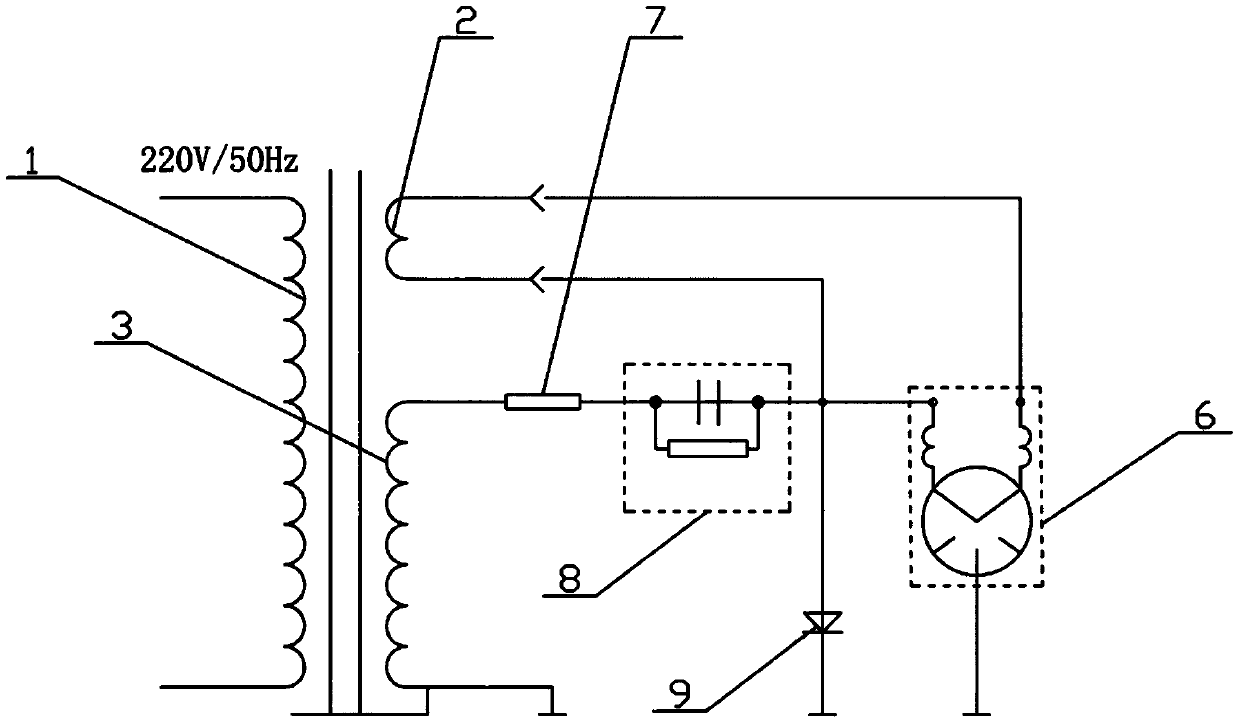

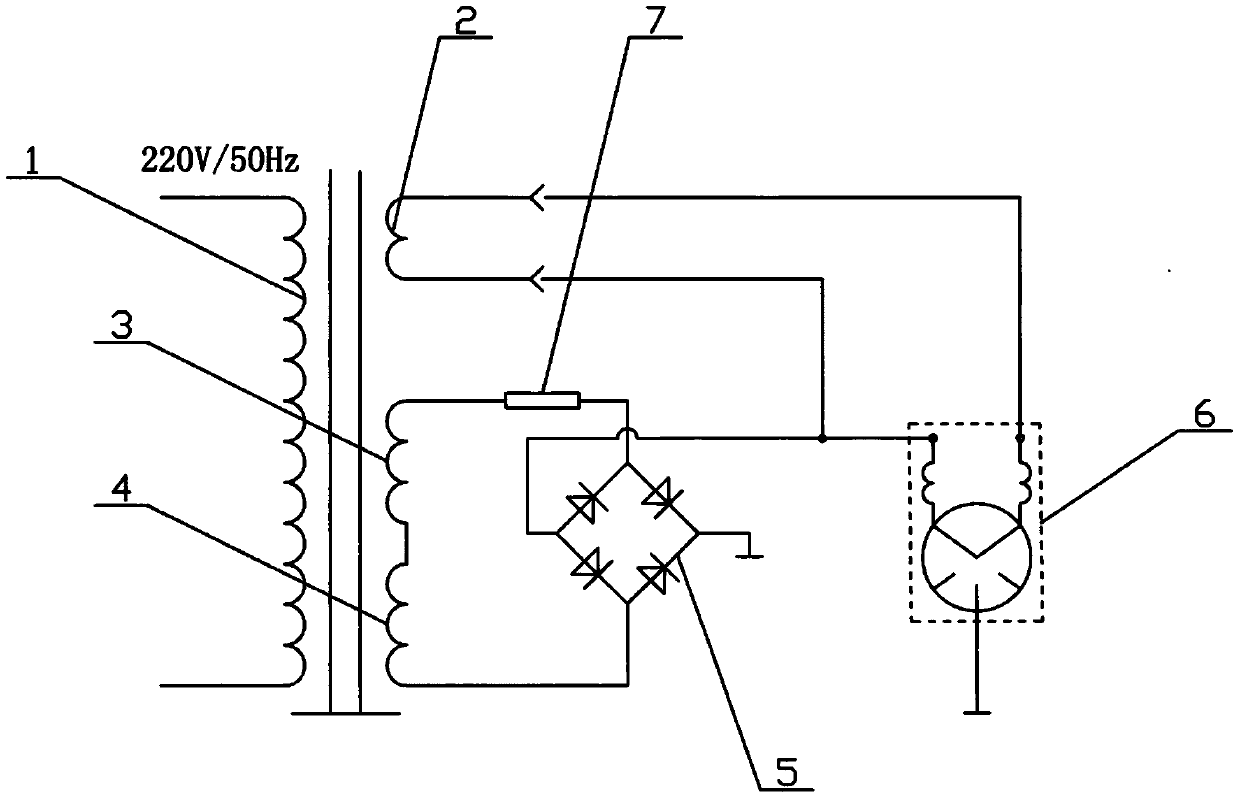

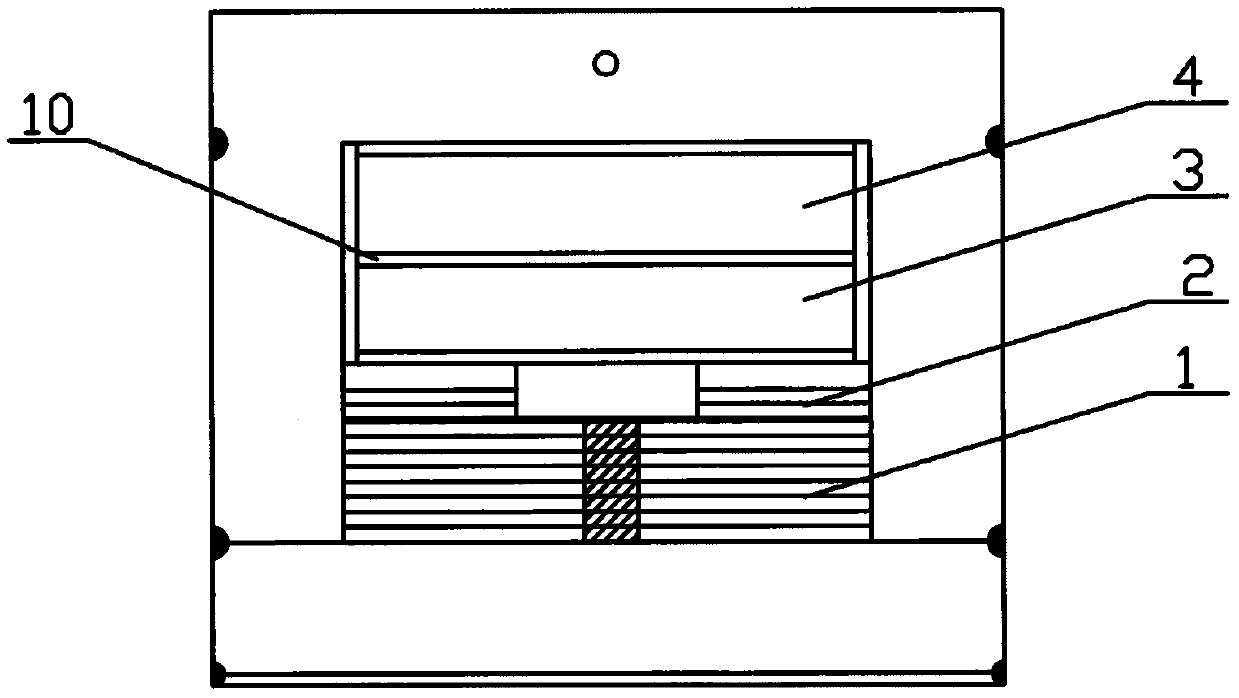

High-voltage separation transformer

PendingCN110085398AReduce voltageGuaranteed pressure safetyTransformersTransformers/inductances coils/windings/connectionsCapacitanceHigh voltage capacitors

The invention relates to a high-voltage separation transformer, which comprises a magnetron, a transformer body and a primary coil and secondary coil thereof, wherein the primary coil and the secondary coil are in coupling connection, the secondary coil includes a secondary B1 coil and at least two secondary B2 coils arranged in a series connection manner; two ends of the secondary B1 coil are electrically connected with the magnetron; and the secondary B2 coils are electrically connected with the magnetron through a high-voltage rectifier bridge circuit, and a fuse tube is connected in seriesin the circuit between the secondary B2 coils. The high-voltage separation transformer is reasonable in design, the voltage is graded through adopting two or more secondary B2 coils, the voltage between the turns of the coils is lowered, the voltage between the layers of the coils remains unchanged, and the withstand voltage safety of the high-voltage transformer is ensured. Meanwhile, the service life of the transformer is prolonged, and the high-voltage capacitor and high-voltage diode voltage doubling circuit part is reduced, thereby enabling the circuit to be more concise, and enabling the system to be more stable.

Owner:山东骏风电子有限公司

Multi-section shell copper pipe sharing double-spacing plate refrigeration heat exchanger

InactiveCN107940813AReduce space consumptionGuaranteed pressure safetyEvaporators/condensersAgricultural engineeringRefrigeration

Multi-section shell copper tubes share a double-baffle refrigeration heat exchanger, including shell, front cover, front partition, partition, rear end cover, rear partition and copper tubes; the shell is a cylindrical cast iron shell, described in multiple sections The casings are connected end to end in series and sealed; the casing of each section is used as the casing of an evaporator of a refrigeration system; the casing of each section is provided with a refrigerant inlet, a refrigerant outlet, an exhaust port and an oil discharge port There are bolt holes on the bottom shell of the front end cover and the edge of the tube shell; the spacer plate is two flanges, which are welded with the shells on the left and right sides respectively; the rear end cover is composed of a cylindrical shell of the outer ring and a spherical The bottom cover is welded; the rear partition is provided with a ring groove; the present invention shares the waterways of the evaporators of multiple refrigeration systems, reduces space occupation, and ensures stable operation at any time according to actual operating conditions.

Owner:梁靖玮

Multi-section pipe-shell type single partition plate cold water evaporator

InactiveCN108106109AReduce space consumptionGuaranteed pressure safetyEvaporators/condensersHeat exchanger casingsWater channelEngineering

The invention discloses a multi-section pipe-shell type single partition plate cold water evaporator. The cold water evaporator comprises a shell, a front end cover, a front separation plate, partition plates, a rear end cover, a rear separation plate and a copper pipe, wherein the shell is a cylindrical cast iron shell, a plurality of sections of the shells are connected in an end-to-end mode inseries and are sealed together; and the shell of each section serves as the shell of the evaporator of a refrigerating system; the shell of each section is provided with a refrigerant inlet, a refrigerant outlet, an exhaust port and an oil discharge port; bolt holes are formed in the edges of a bottom shell and a pipe shell of the front end cover; two ends of the partition plates are correspondingly welded to the ends of the two sections of the shells; and a water cavity is formed between the rear end cover and the rear partition plate; and the copper pipe is arranged in the shell. According to the multi-section pipe-shell type single partition plate cold water evaporator, water channels of the evaporators of the refrigerating systems are shared, so that space occupation is reduced; and the operation under a stable working condition can be guaranteed at any time according to the actual operation condition.

Owner:杨 萍

Multi-section pipe-shell type double partition plate cold water evaporator

InactiveCN108106111AReduce space consumptionGuaranteed pressure safetyEvaporators/condensersEngineeringFlange

The invention discloses a multi-section pipe-shell type double partition plate cold water evaporator. The cold water evaporator comprises a shell, a front end cover, a front separation plate, partition plates, a rear end cover, a rear separation plate and a copper pipe, wherein the shell is a cylindrical cast iron shell; a plurality of sections of the shell are connected in an end-to-end mode in series and are sealed together; and the shell of each section serves as the shell of the evaporator of a refrigerating system; the shell of each section is provided with a refrigerant inlet, a refrigerant outlet, an exhaust port and an oil discharge port; bolt holes are formed in the bottom shell of the front end cover and the edge of the pipe shell; and the partition plates are two flange plates,and are welded with the shell on the left side and the shell on the right side correspondingly; a water cavity is formed between the rear end cover and the rear partition plate; and the copper pipe isarranged in the shell. According to the invention, water channels of the evaporators of the refrigerating system are shared, so that space occupation is reduced; and the operation under a stable working condition can be guaranteed at any time according to the actual operation condition.

Owner:杨 萍

Refrigeration evaporator with multiple outer shell sections and single space plates

InactiveCN108106120AReduce space consumptionGuaranteed pressure safetyEvaporators/condensersHeat exchanger casingsCopperRefrigeration

A refrigeration evaporator with multiple outer shell sections and single space plates comprises an outer shell, a front end cover, a front space plate, the space plates, a rear end cover, a rear spaceplate and a copper pipe. The outer shell is a cylindrical cast iron outer shell. The multiple outer shell sections are connected end to end in series and sealed. Each outer shell section is used as an outer shell body of an evaporator body of a refrigeration system and provided with a refrigerant inlet, a refrigerant outlet, an exhaust port and an oil discharging outlet. A bottom shell of the front end cover is shaped like the number '8'. The two ends of each space plate are welded to the ends of the corresponding outer shell sections correspondingly. The rear end cover is formed by welding acylindrical shell on the outer ring with a spherical-surface-shaped bottom cover. The copper pipe is arranged in the outer shell. The evaporator bodies of multiple refrigeration systems share a waterchannel, the occupied space is reduced, and stable operation under the working conditions is ensured at any time according to the actual operation working conditions.

Owner:龙炽坚

Multi-section shell shell-tube double-spacing-plate cold water heat exchanger

InactiveCN108106099AReduce space consumptionGuaranteed pressure safetyEvaporators/condensersEngineeringRefrigeration

The invention discloses a multi-section shell shell-tube double-spacing-plate cold water heat exchanger. The multi-section shell shell-tube double-spacing-plate cold water heat exchanger comprises shells, a front end cover, a front separation plate, spacing plates, a back end cover, a back separation plate and copper pipes; the shells are cylindrical cast iron shells; multiple sections of the shells are serially connected end to end and sealed; each section of the shell serves as a shell of an evaporator of a refrigeration system; each section of the shell is provided with a refrigerant inlet,a refrigerant outlet, an exhaust port and an oil discharge port; bolt holes are formed in the edges of a bottom shell of the front end cover and a tube shell; the spacing plates are two flange plates, and are respectively welded with the shells on the left and right sides; a water cavity is formed between the back end cover and the back separation plate; and the back separation plate is providedwith a ring groove. Water ways of evaporators of multiple refrigeration systems are shared, so that occupied space is reduced; and operation under stable working conditions is guaranteed according toactual operation working conditions at any time.

Owner:杨 萍

Refrigeration evaporator with multiple sections of outer shells and double separation plates

InactiveCN108120071AReduce space consumptionGuaranteed pressure safetySpacing meansSafety devices for heat exchange apparatusEngineeringRefrigerant

A refrigeration evaporator with multiple sections of outer shells and double separation plates comprises the outer shells, a front end cover, a front separation plate, the separation plates, a rear end cover, a rear separation plate and a copper pipe, wherein the outer shells are cylindrical cast iron outer shells, and the multiple sections of the outer shells are in series connection end to end and sealed; each section of the outer shell serves as an outer shell of an evaporator of a refrigerating system; each section of the outer shell is provided with a refrigerant inlet, a refrigerant outlet, an exhaust port and an oil discharge outlet; a bottom shell of the front end cover is in a shape like an Arabic number eight; the separation plates are two flange plates and are welded to the outer shells on the left and on the right respectively; the rear end cover is formed by welding a cylindrical shell of an outer ring and a spherical surface bottom cover; and the copper pipe is in the outer shells. Water channels of evaporators of multiple refrigerating systems are shared, so space occupation is reduced, and operation under stable working conditions is guaranteed according to actual operation conditions at any time.

Owner:龙炽坚

Multi-section shell and copper pipe shared single-spacing-board refrigeration evaporator

InactiveCN108106104AReduce space consumptionGuaranteed pressure safetyEvaporators/condensersEngineeringRefrigeration

The invention discloses a multi-section shell and copper pipe shared single-spacing-board refrigeration evaporator. The multi-section shell and copper pipe shared single-spacing-board refrigeration evaporator comprises shells, a front end cover, a front partition plate, a spacing board, a rear end cover, a rear partition plate and copper pipes. The shells are cylindrical cast iron shells, and themultiple sections of the shells are connected end to end to be connected together in series and be sealed. Each section of the shell serves as an evaporator shell of a refrigeration system and is further provided with a refrigerating fluid inlet, a refrigerating fluid outlet, an air exhaust outlet and an oil drain outlet. A bottom shell of the front end cover and the tube-shell edge are provided with bolt holes. The two ends of the spacing board are welded to the ends of the two sections of the shells separately. The rear end cover is formed by welding a cylindrical shell of an outer ring andspherical bottom cover. The copper pipes are arranged inside the corresponding shells. According to the multi-section shell and copper pipe shared single-spacing-board refrigeration evaporator, waterroutes of the evaporators of the multiple refrigeration systems are shared, space occupancy is reduced, and the effect that the multi-section shell and copper pipe shared single-spacing-board refrigeration evaporator operates under the stable working condition can be guaranteed at any moment according to the actual operation conditions.

Owner:杨 萍

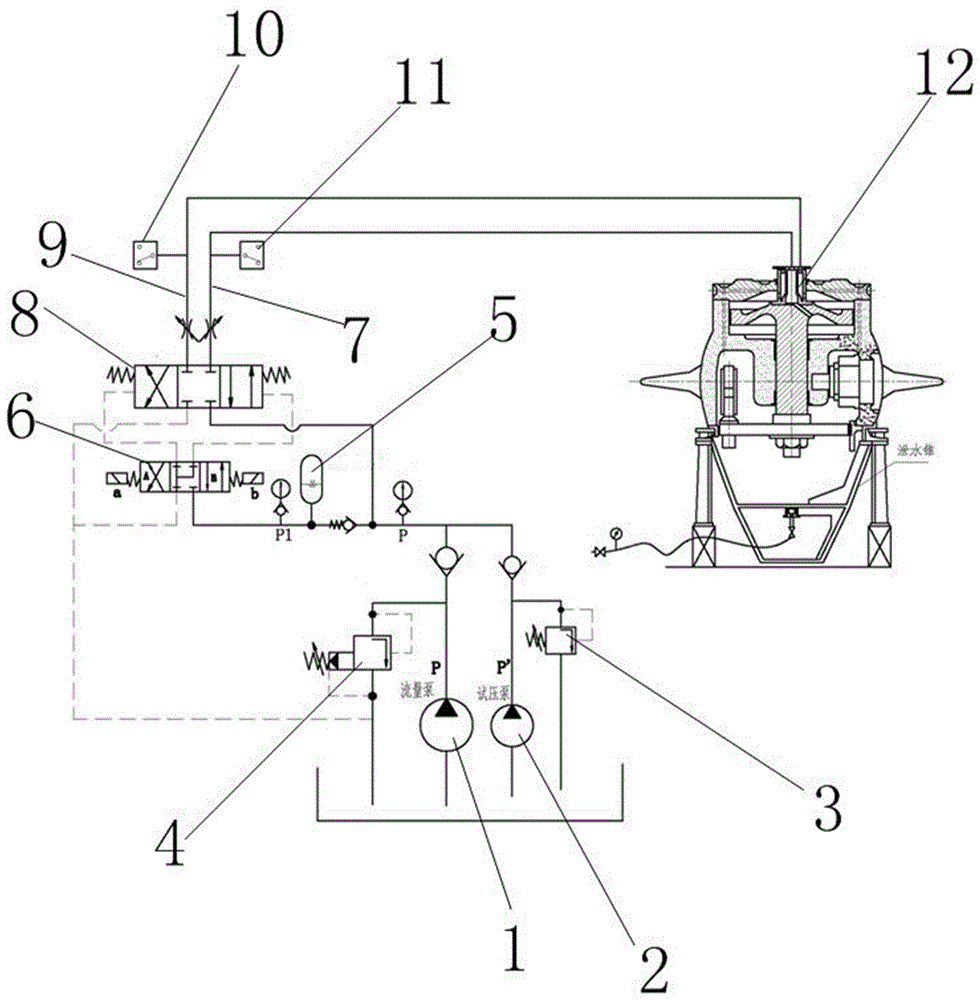

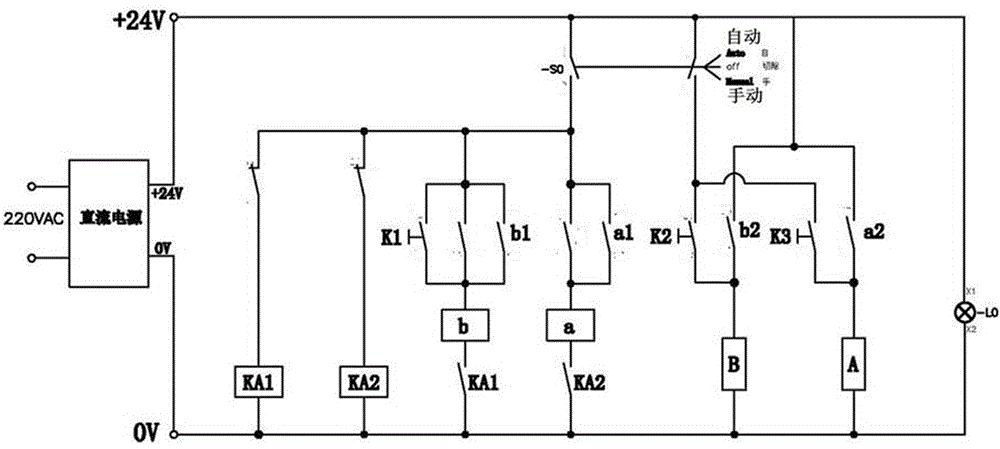

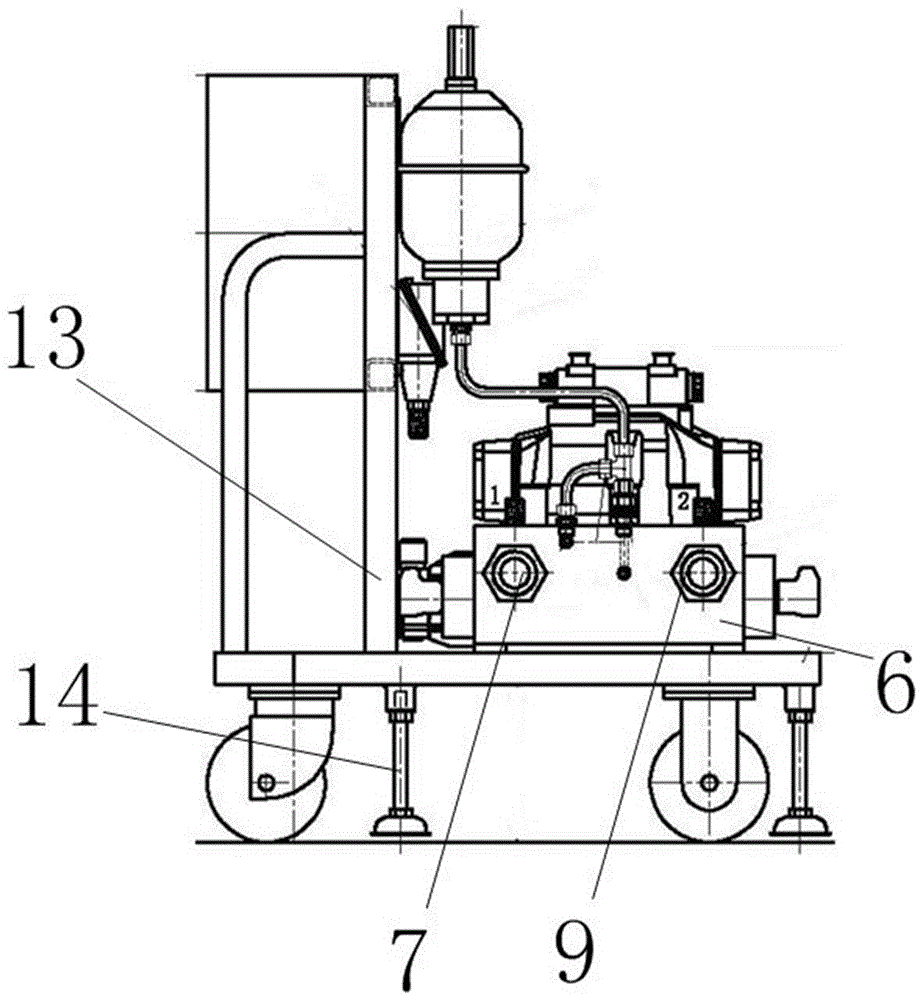

Electrohydraulic control method and device for axial flow propeller turbine runner tests

PendingCN107524640ARealize automatic full opening and closingRealize no-load startMachine gearing/transmission testingAccumulator installationsWater turbinePropeller

The invention provides electrohydraulic control method and device for axial flow propeller turbine runner tests. The control device comprises a flow pump, a pressure testing pump, an oil circuit and an oil pressure controlling mechanism, wherein the flow pump and the pressure testing pump are connected with a to-be-tested axial flow propeller turbine runner via the oil circuit; the oil pressure controlling mechanism comprises an electrohydraulic reversing component; the electrohydraulic reversing component comprises an electrohydraulic reversing valve for control, an electrohydraulic reversing valve for business and an energy accumulator; the electrohydraulic reversing valve for control and the electrohydraulic reversing valve for business are connected to increase the driving force of the oil circuit; the oil circuit from the electrohydraulic reversing valve for business to a turbine runner comprises a positive swing oil circuit and a negative swing oil circuit; an output end of the electrohydraulic reversing valve for business is provided with a positive swing switch group and a negative swing switch group which have mutually-exclusive trigger states; and both the positive swing switch group and the negative swing switch group have two operating modes of hydraulic trigger and manual trigger. By means of the method and the device which are provided by the invention, the axial flow propeller turbine runner can be safely and conveniently tested.

Owner:STATE GRID FUJIAN ELECTRIC POWER CO LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com