Cold water heat exchanger with multiple shells and double spacing boards

A partition plate and heat exchanger technology, which is applied in the direction of heat exchanger shell, evaporator/condenser, refrigerator, etc., can solve the problem of limited evaporator space and achieve the effect of reducing space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

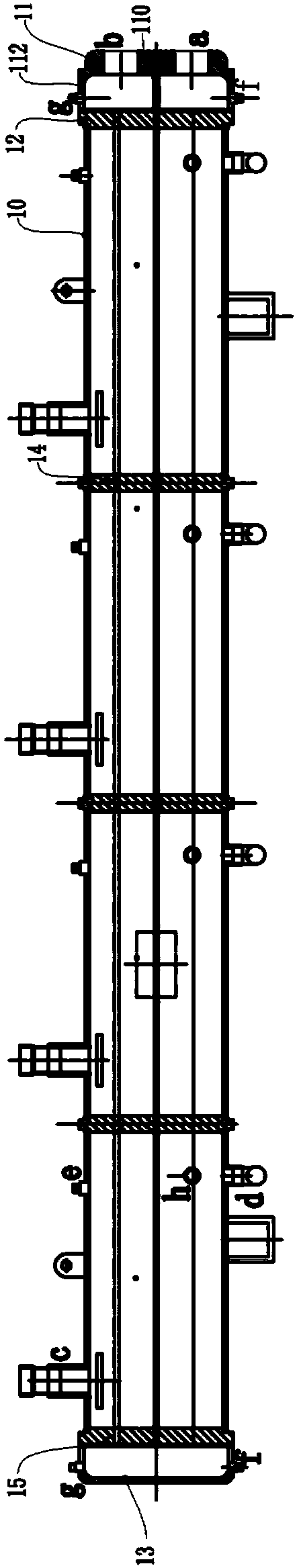

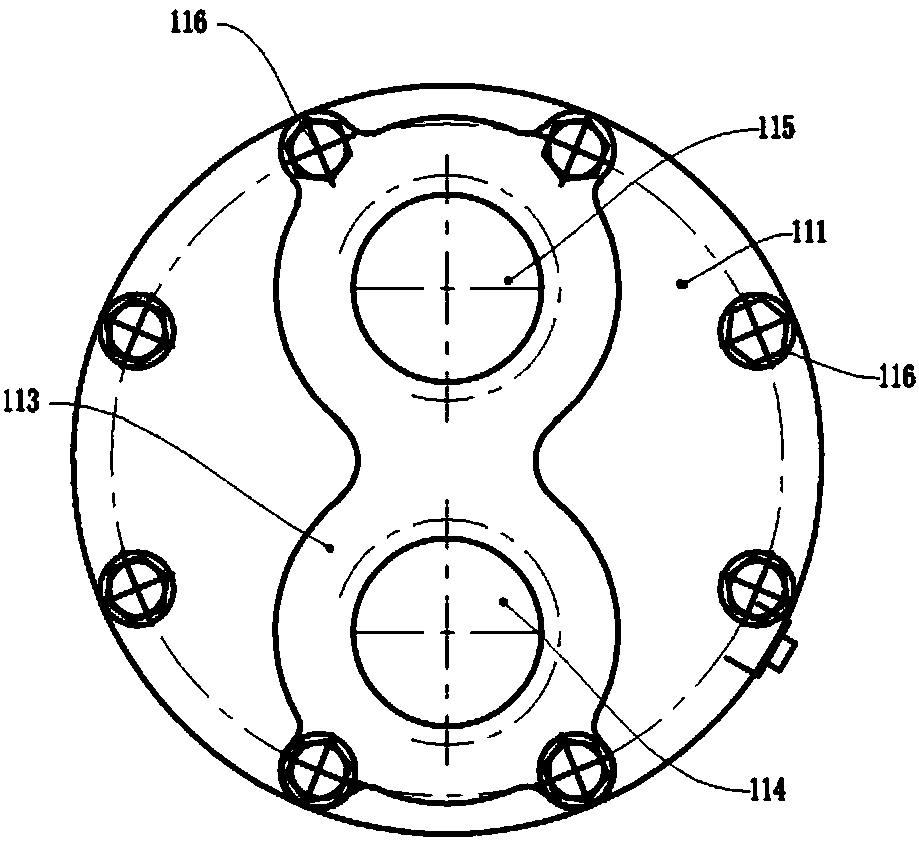

[0019] A cold water heat exchanger with multiple shells and double partitions, including a shell 10, a front cover 11, a front partition 12, a partition 14, a rear end cover 13, a rear partition 15 and copper tubes; the shell 10 is a cylindrical cast iron shell , multiple sections of the shell 10 are connected end to end in series and sealed together; the shell 10 of each section is used as the shell of an evaporator of a refrigeration system; the shell 10 of each section is provided with a refrigerant inlet h and a refrigerant outlet c. Exhaust port e and oil discharge port d; the exhaust port e is welded with a sleeve, and then an exhaust valve is installed on the sleeve; the exhaust valve includes a hollow cylindrical copper shell, which is cushioned on the cylindrical copper shell The gasket on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com