Cold water evaporator with multi sections of shells and copper pipe sharing single partition plate

A technology of evaporator and partition plate is applied in the field of single partition plate cold water evaporator shared by multi-section shell copper pipes, which can solve the problem of limited space of the evaporator and achieve the effect of reducing space occupation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

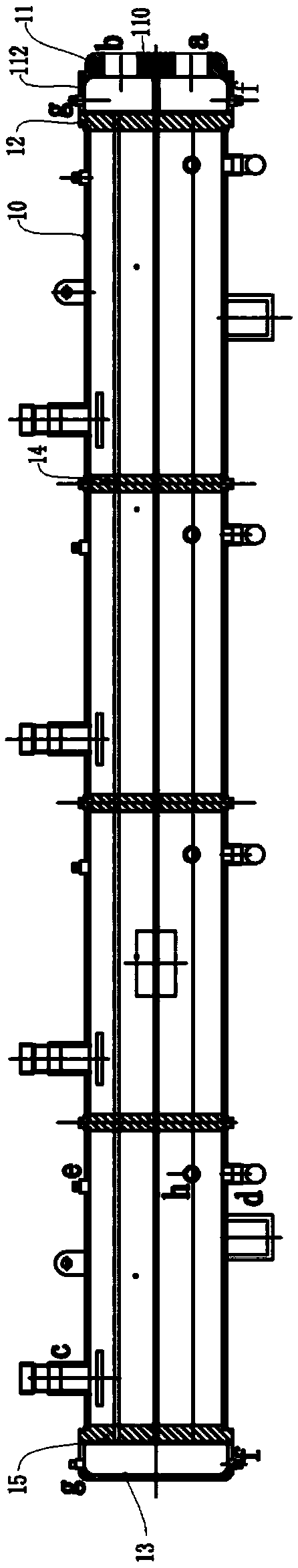

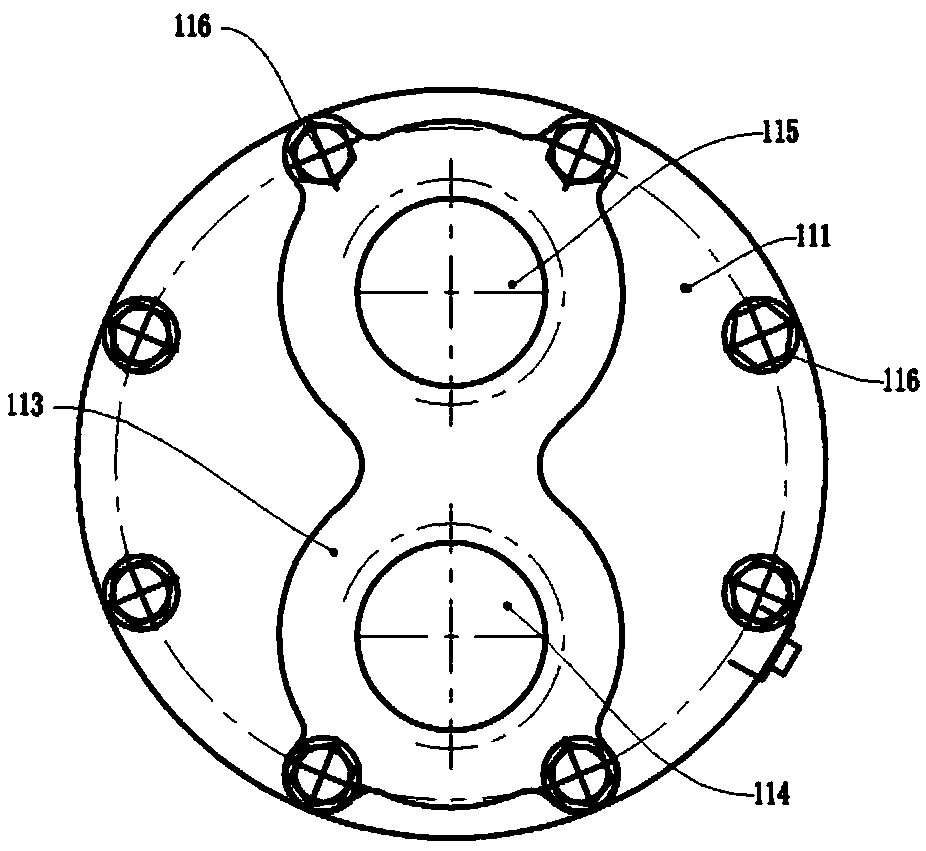

[0019] Multi-section shell copper pipes share a single partition cold water evaporator, including a shell 10, a front cover 11, a front partition 12, a partition 14, a rear end cover 13, a rear partition 15 and copper pipes; the casing 10 is cylindrical Cast iron shell, multiple sections of the shell 10 are connected end to end in series and sealed; the shell 10 of each section is used as the shell of an evaporator of a refrigeration system; the shell 10 of each section is provided with a refrigerant inlet h, refrigeration agent outlet c, exhaust port e and oil discharge port d; the exhaust port e is welded with a sleeve, and then an exhaust valve is installed on the sleeve; the exhaust valve includes a hollow cylindrical copper shell, cushioned on a cylindrical A gasket on the end face of the coppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com