An Adaptive Hydrogen Production System

A hydrogen production system and self-adaptive technology, applied in the field of hydrogen production, can solve the problems of consumption of hydrogen, fast aging of gas permeable membrane, and failure to solve the source of hydrogen, and achieve automatic recovery and discharge, fuel feeding process and waste liquid discharge process. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

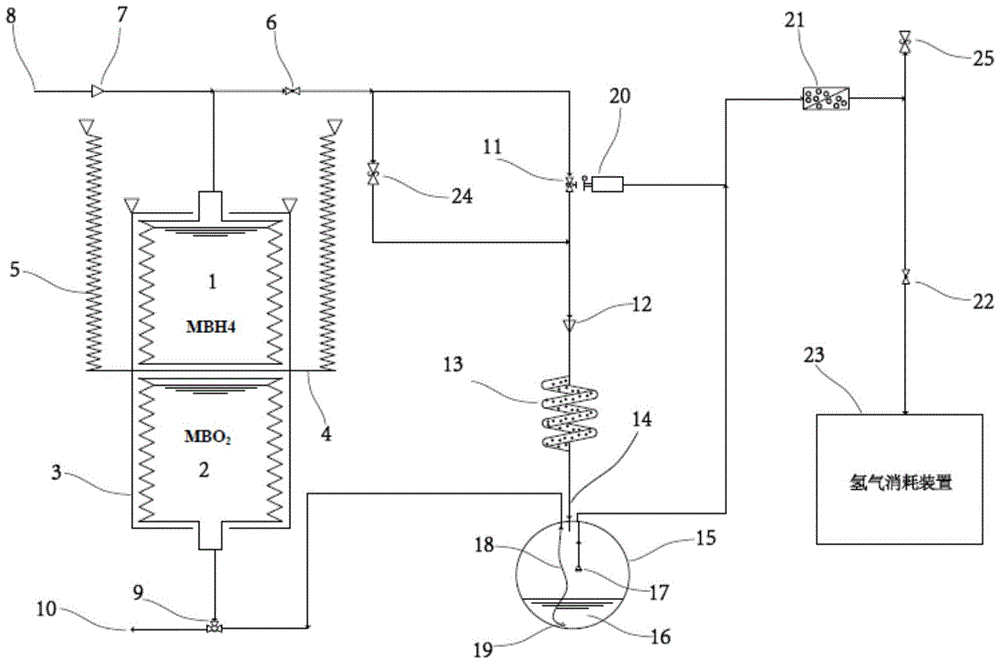

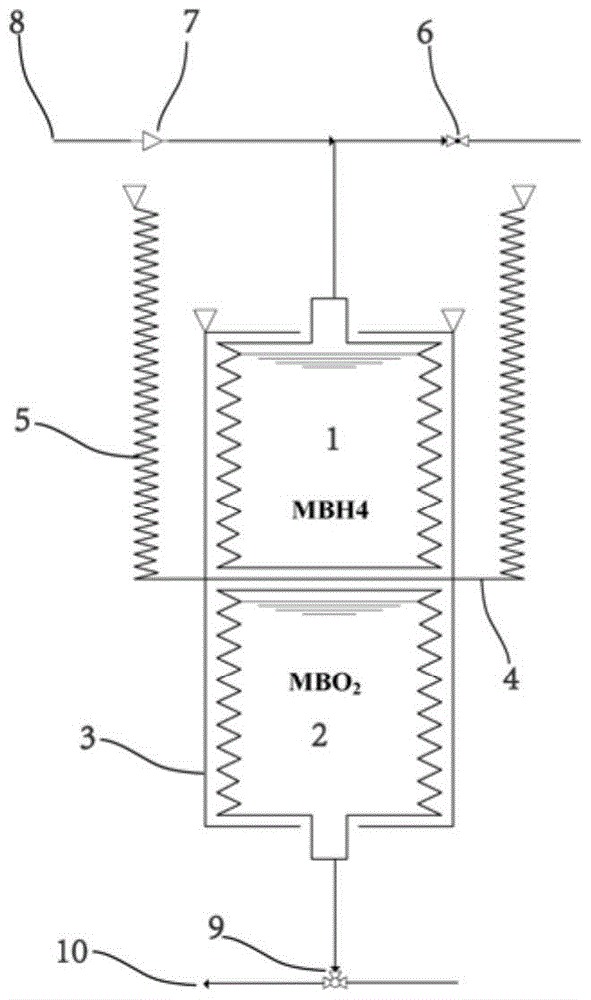

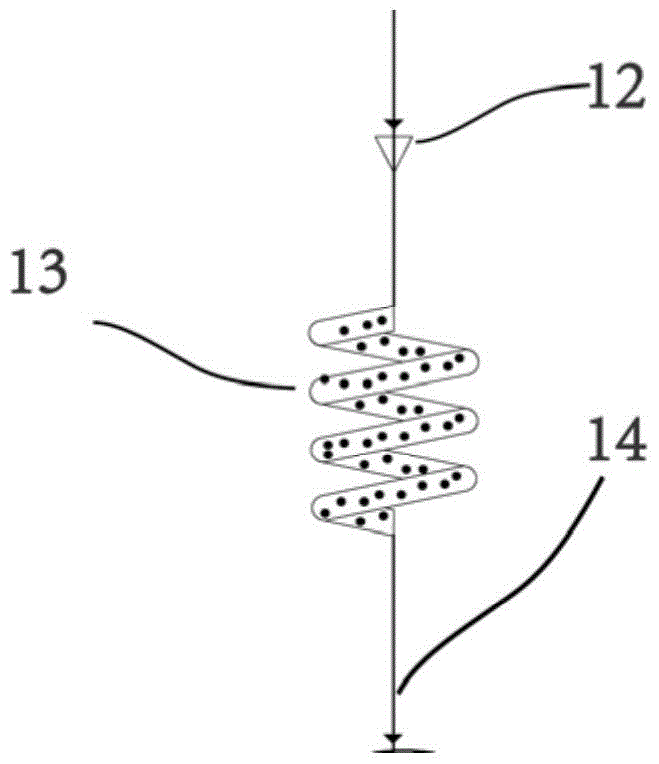

[0027] The invention provides an adaptive hydrogen production system related to alkali metal borohydrides. The alkali metals in compounds such as alkali metal borohydrides are metal elements represented by Group 1 or Group 2 in the periodic table of elements, such as lithium and sodium , potassium, calcium and magnesium, etc., the corresponding borohydride is LiBH 4 , NaBH 4 、KBH 4 , Ca(BH 4 ) 2 and Mg(BH 4 ) 2 . The above-mentioned basic metal borohydride can be dissolved in water, and under the action of a catalyst, the basic metal borohydride will undergo a hydrolysis reaction. Taking sodium borohydride as an example, its hydrolysis chemical reaction formula is:

[0028]

[0029] The alkaline metal borohydride solution will undergo self-hydrolysis reaction. In order to reduce the rate of self-hydrolysis, when configuring the alkaline metal borohydride aqueous solution, add a certain amount of alkali solution corresponding to the basic metal element, such as for NaB...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com