Air quantity determining method of meeting cooling requirements of extra-high voltage direct-current thawing device

A UHV DC, determination method technology, applied in the field of air volume determination that meets the cooling requirements of UHV DC ice-melting devices, can solve problems such as design errors, design difficulties, and simple design processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

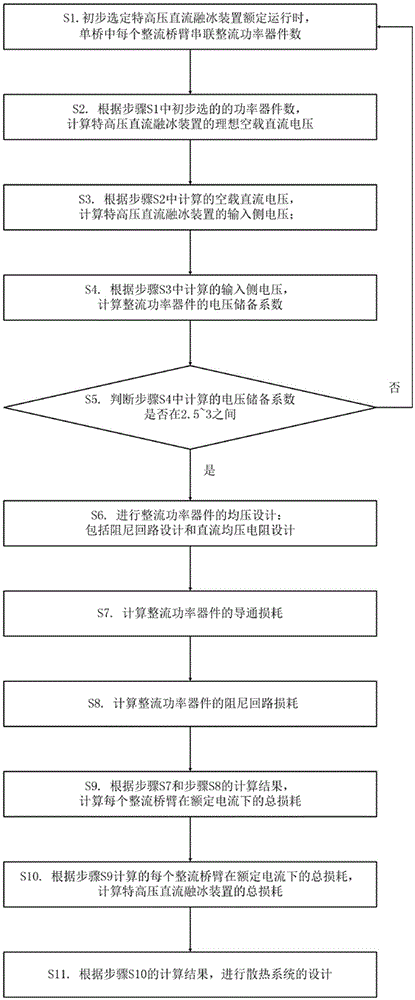

[0065] like figure 1 Shown is the schematic flow chart of the method of the present invention: the pressure-resistant and heat-dissipating design method of the UHV DC ice-melting device of the present invention specifically includes the following steps:

[0066] S1. According to the rated operating parameters of the UHV DC ice-melting device, the number of rectifier power devices connected in series for each rectifier bridge arm in the single bridge is preliminarily selected:

[0067] Based on experience, the designer preliminarily selects the number of series rectifier power devices in a single rectifier bridge arm when the UHV DC deicing device is in rated operation;

[0068] S2. Calculate the ideal no-load DC voltage of the UHV DC deicing device according to the number of power devices initially selected in step S1;

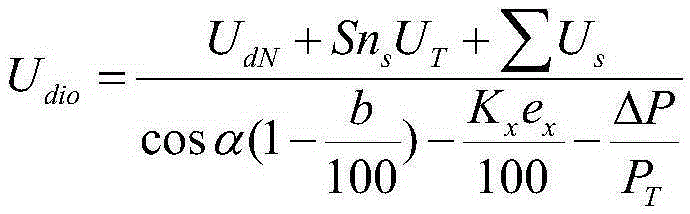

[0069] The formula for calculating the ideal no-load DC voltage is

[0070] U d i o ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com