Battery structure test tool design method and system, storage medium and equipment

A technology of structural testing and design methods, applied in the direction of design optimization/simulation, etc., can solve problems such as difficulty in controlling whether the test tooling meets the requirements, inability to fundamentally grasp the design method of the battery structure test tooling, and defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

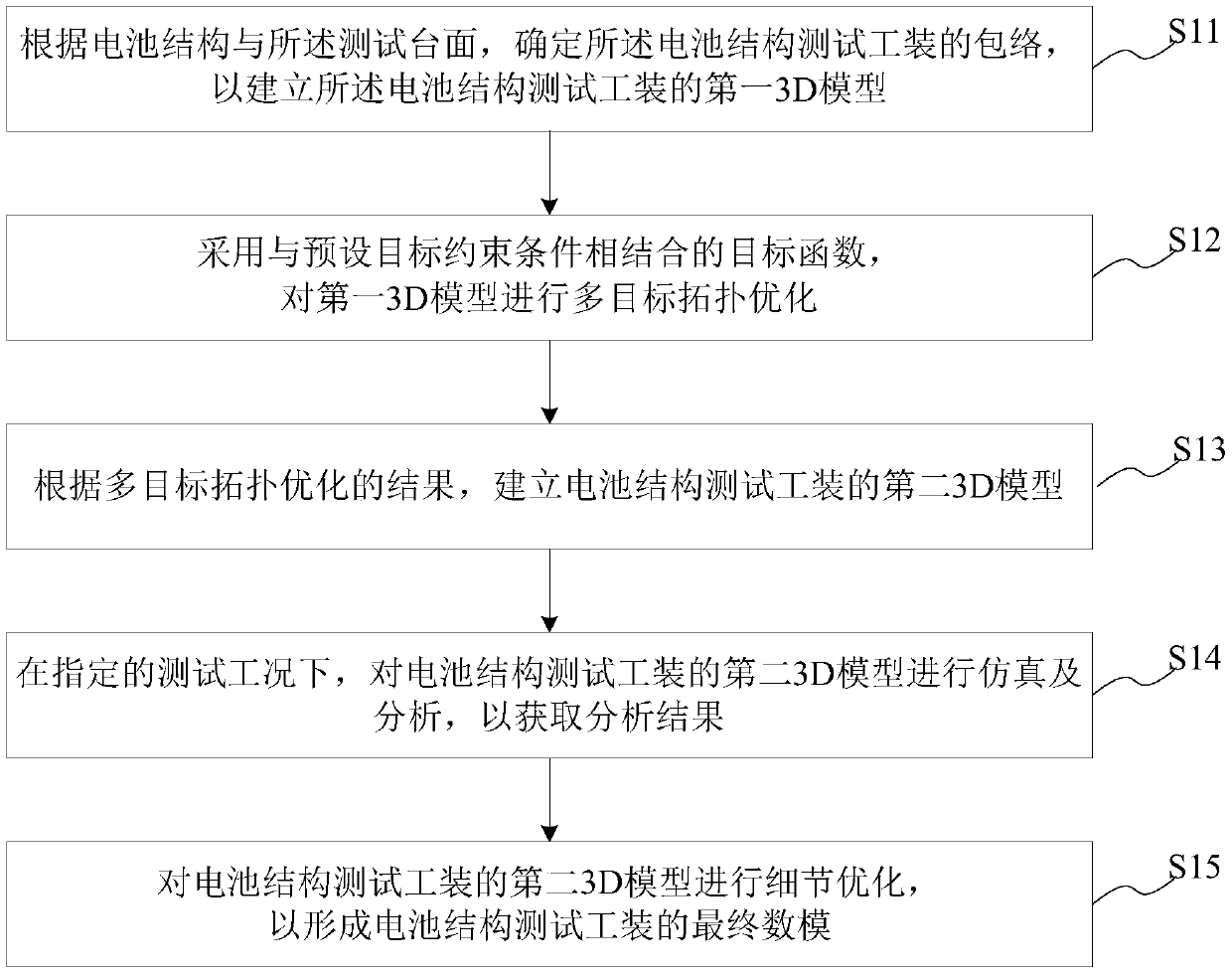

[0047] This embodiment provides a design method of a battery structure test tool, the battery structure test tool is fixed on a test table, and the design method of the battery structure test tool includes:

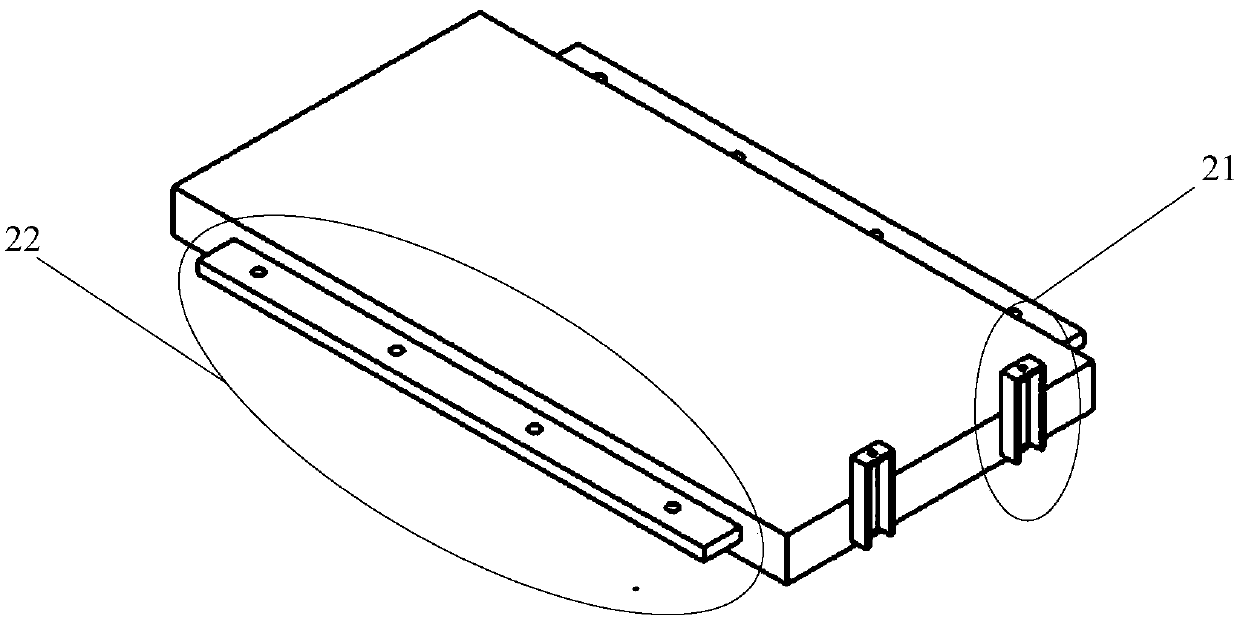

[0048] determining an envelope of the battery structure test tool according to the battery structure and the test table, so as to establish a first 3D model of the battery structure test tool;

[0049] performing multi-objective topology optimization on the first 3D model by using an objective function combined with preset objective constraints;

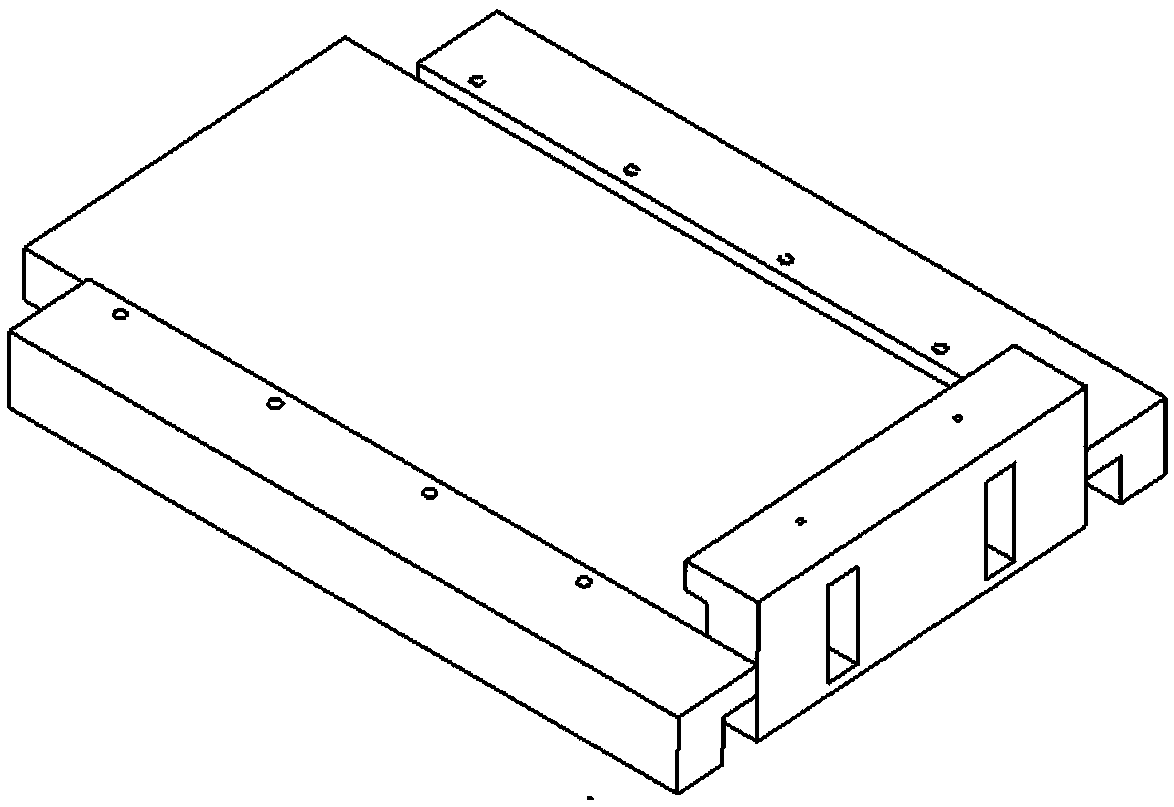

[0050] Establishing a second 3D model of the battery structure test tooling according to the results of multi-objective topology optimization;

[0051] Under specified test conditions, simulating and analyzing the second 3D model of the battery structure test tooling to obtain analysis results;

[0052] According to the analysis results, use requirements and / or installation requirements, the details of the second 3D model of th...

Embodiment 2

[0089] This embodiment provides a design system for a battery structure test tool, the battery structure test tool is fixed on a test table, and the design system for the battery structure test tool includes:

[0090] A first model building module, configured to determine the envelope of the battery structure test tool according to the battery structure and the test table, so as to establish a first 3D model of the battery structure test tool;

[0091] A topology optimization module, configured to perform multi-objective topology optimization on the first 3D model by using an objective function combined with preset objective constraints;

[0092] The second model building module is used to create a second 3D model of the battery structure test tool according to the results of multi-objective topology optimization;

[0093] The simulation analysis module is used to simulate and analyze the second 3D model of the battery structure test tool under specified test conditions to obt...

Embodiment 3

[0117] This embodiment provides a device, which includes: a processor, a memory, a transceiver, a communication interface or / and a system bus; the memory and the communication interface are connected to the processor and the transceiver through the system bus and complete mutual communication, and the memory The computer program is stored, the communication interface is used to communicate with other devices, the processor and the transceiver are used to run the computer program, so that the x device executes the steps of the above x method.

[0118] The system bus mentioned above may be a Peripheral Component Interconnect (PCI for short) bus or an Extended Industry Standard Architecture (EISA for short) bus or the like. The system bus can be divided into address bus, data bus, control bus and so on. The communication interface is used to realize the communication between the database access device and other devices (such as client, read-write library and read-only library). ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com