Multi-section shell copper pipe sharing double-spacing plate refrigeration heat exchanger

The technology of heat exchanger and partition plate is applied in the field of double-partition plate refrigeration heat exchanger shared by multi-section outer shell copper tubes, which can solve the problems of limited space of the evaporator and achieve the effect of reducing space occupation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

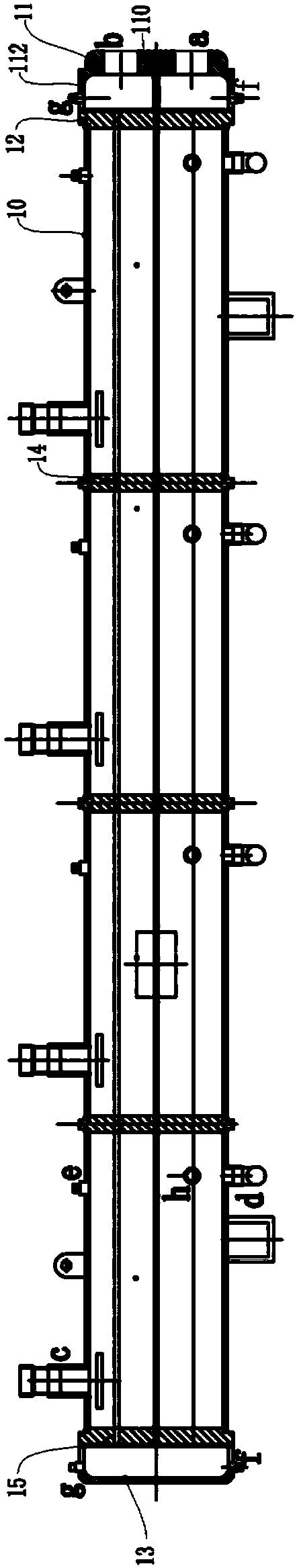

[0018] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

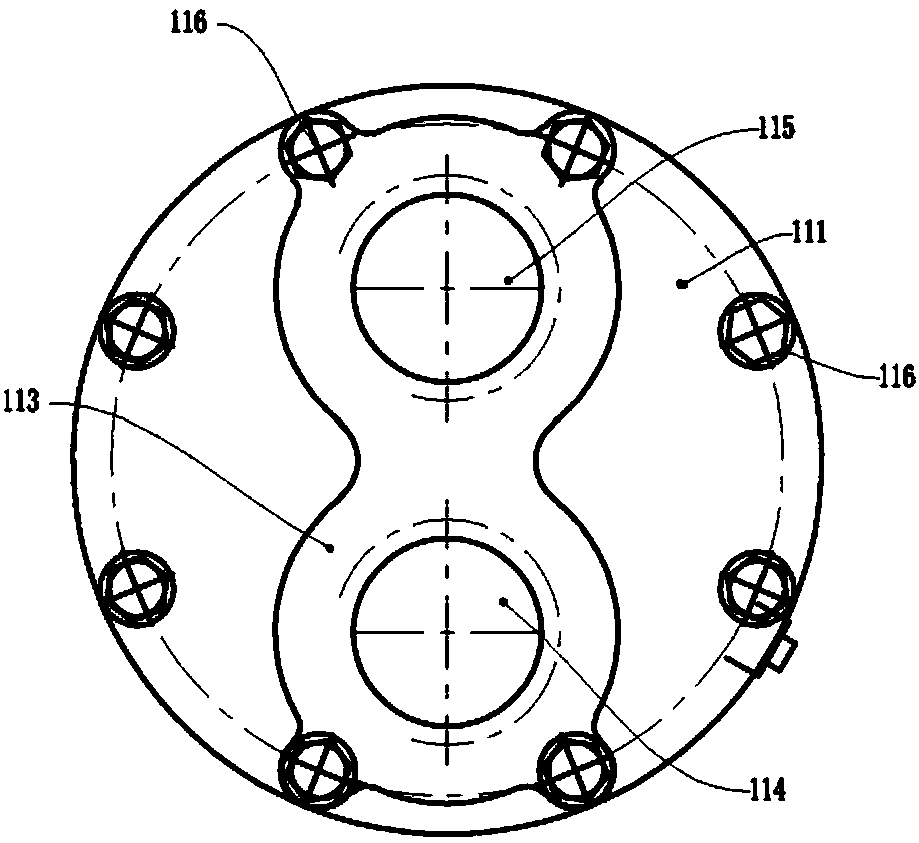

[0019] Multi-section shell copper tubes share double-baffle refrigeration heat exchanger, including shell 10, front cover 11, front partition 12, partition 14, rear end cover 13, rear partition 15 and copper tubes; the shell 10 is cylindrical The cast iron shell of multiple sections of the shell 10 is connected end to end in series and sealed; the shell 10 of each section is used as the shell of an evaporator of a refrigeration system; the shell 10 of each section is provided with a refrigerant inlet h, Refrigerant outlet c, exhaust port e and oil discharge port d; the exhaust port e is welded with a sleeve, and then an exhaust valve is installed on the sleeve; the exhaust valve consists of a hollow cylindrical copper shell, cushioned on A gasket on the end face of the cylindrical copper shell, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com