Brittle material base board parting tool and brittle material base board supporting fixture

A technology of brittle material substrates and support clips, which is applied in the direction of manufacturing tools, stone processing equipment, fine working devices, etc., can solve the problems of large and expensive devices, unsuitable for cutting, etc., and achieve the effect of preventing damage and suppressing protruding corners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

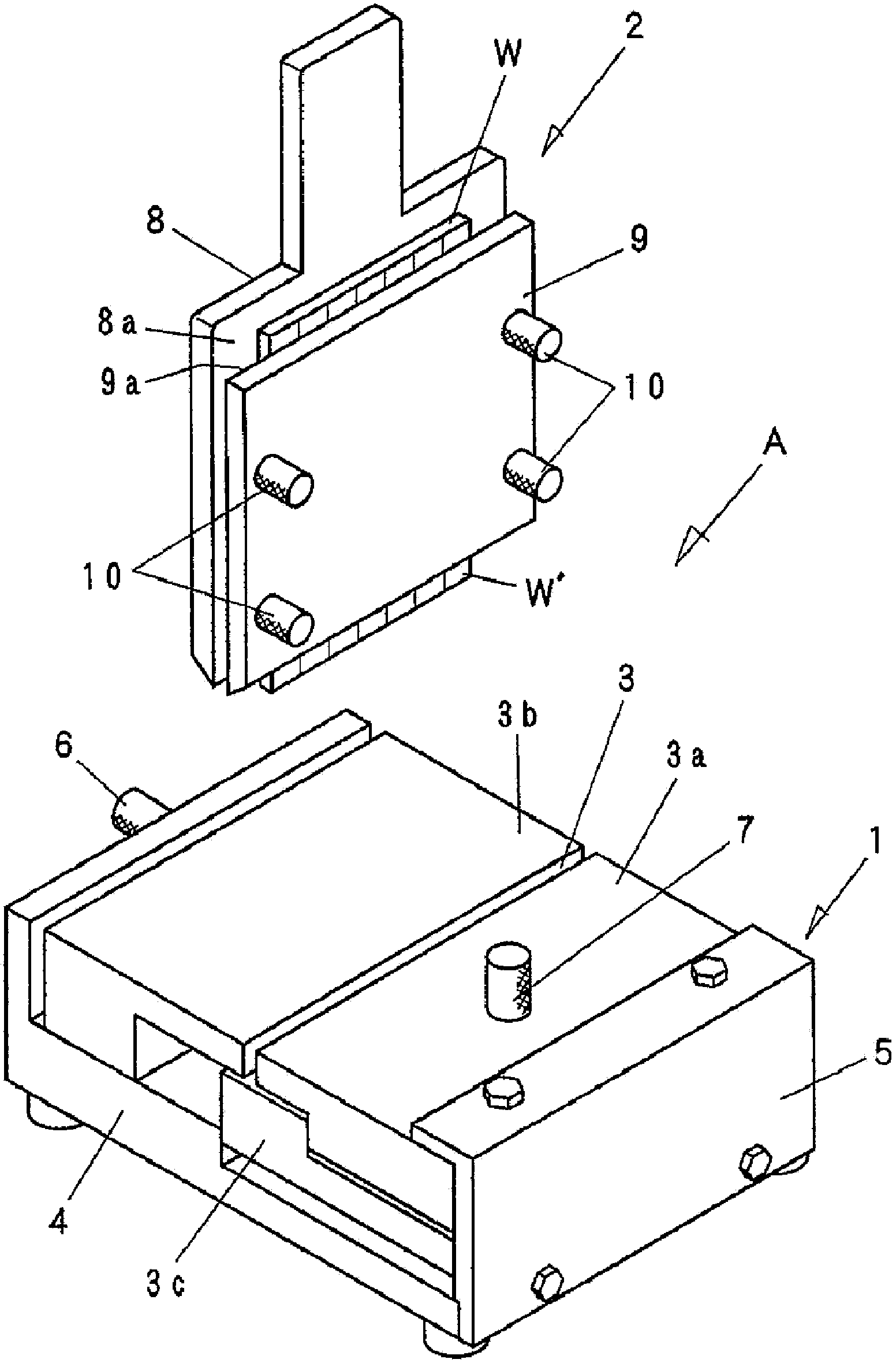

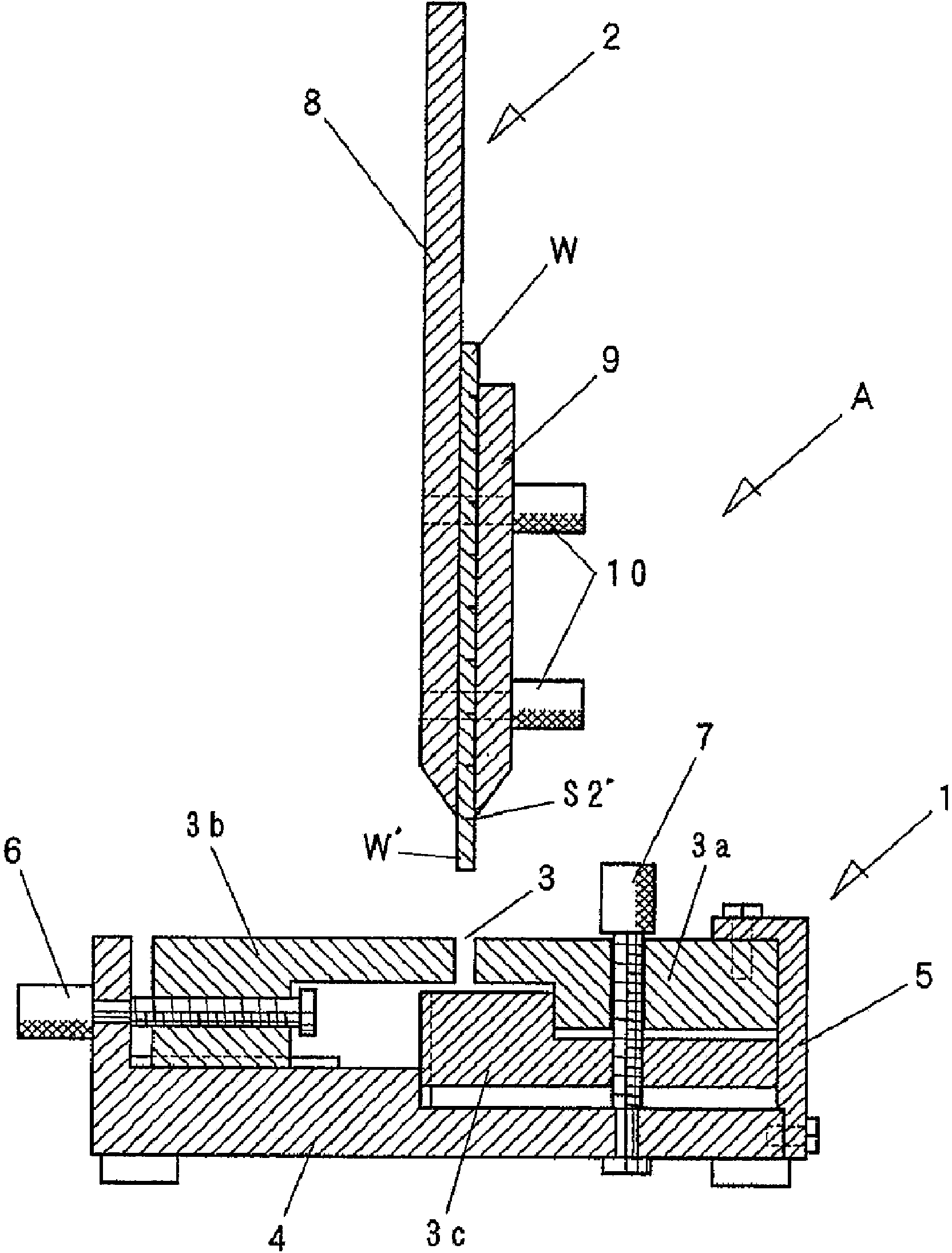

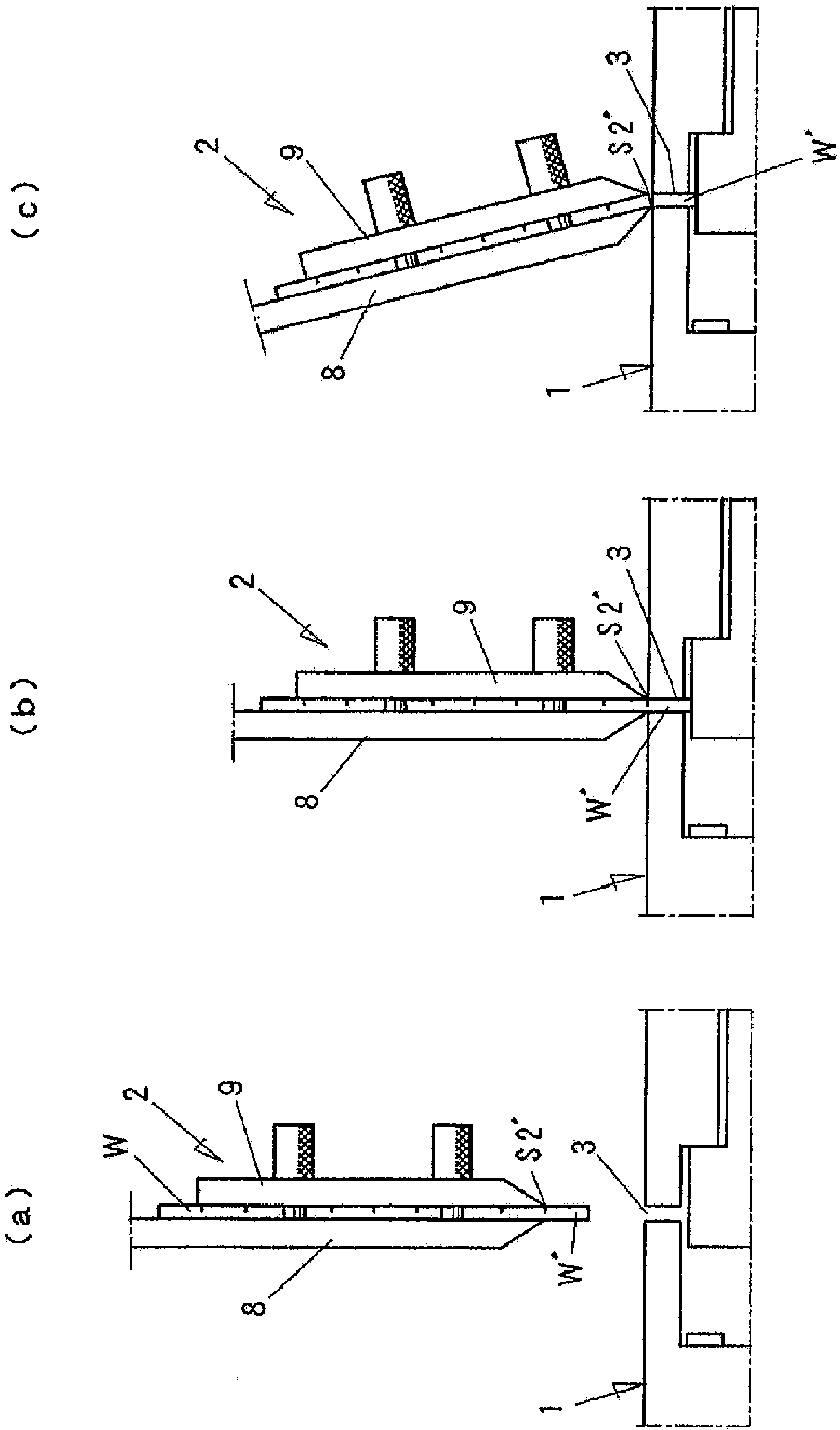

[0050] Below, based on Figure 1-11 The cutting tool of the present invention will be described in detail.

[0051] The cutting tool A of the present invention includes: a support jig 1 having a linear groove 3 on the surface into which one end portion of the substrate W is inserted; ( figure 1 The substrate W is sandwiched and held in a state where the lower end of the substrate W protrudes. Figure 1~3 is a drawing related to the clamping jig of the first embodiment, Figure 4~6 is a drawing related to the insertion jig of the second embodiment, Figure 7-10 It is a figure related to the insertion jig of 3rd Embodiment.

[0052] The support fixture 1 includes: a fixed side wall part 3a forming one side wall of the groove 3; a movable side wall part 3b forming the other side wall; a movable bottom plate part 3c forming the bottom surface of the groove 3; and a workbench 4 , keep these components.

[0053] The fixed side wall member 3 a is fixed to the table 4 via the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com