Material filling and blank fetching all-in-one machine of automatic forming equipment

An automatic forming, integrated machine technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of failing to meet the production and manufacturing requirements of enterprises, high manufacturing costs, low production efficiency, etc., and achieve low cost, easy to manufacture, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

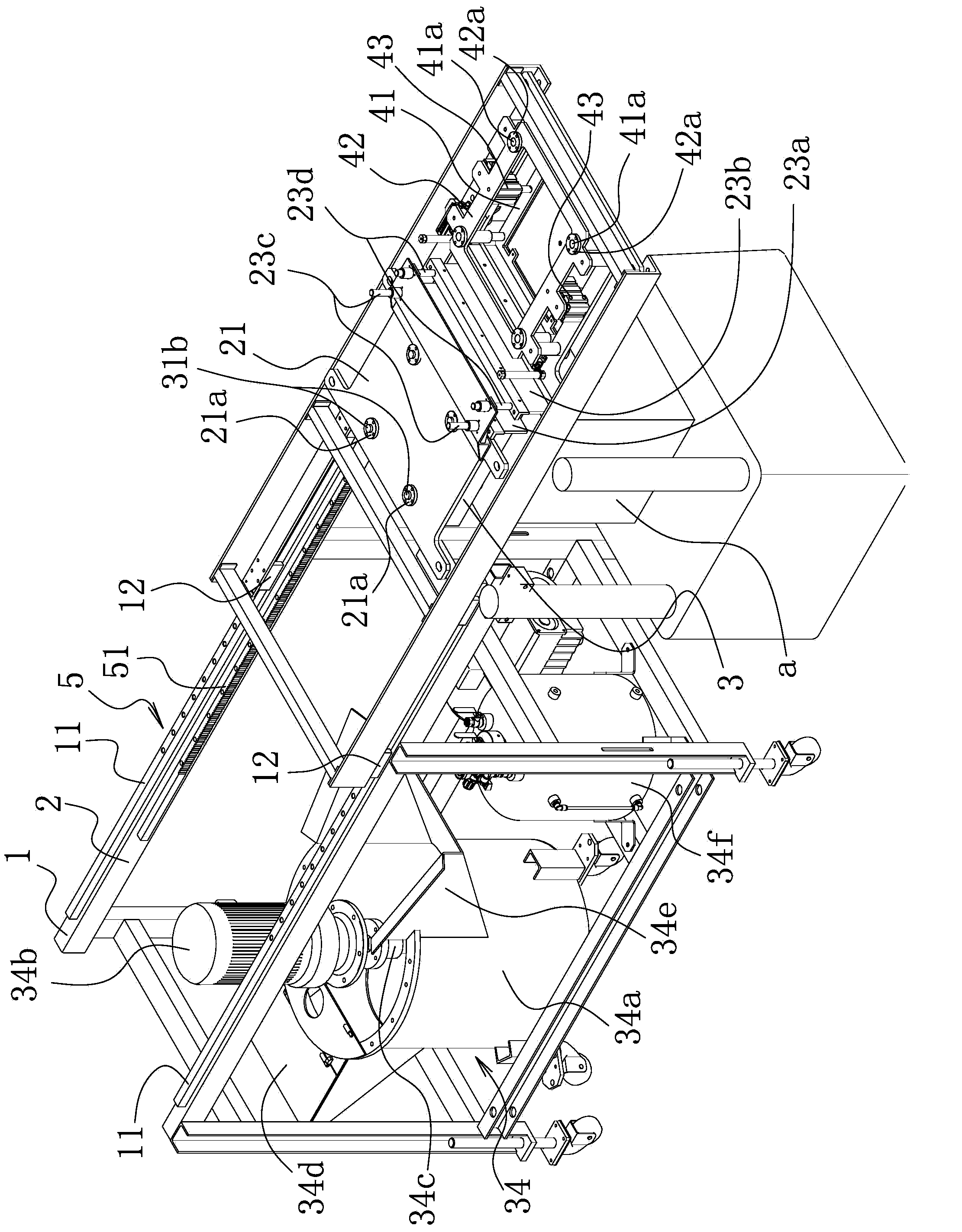

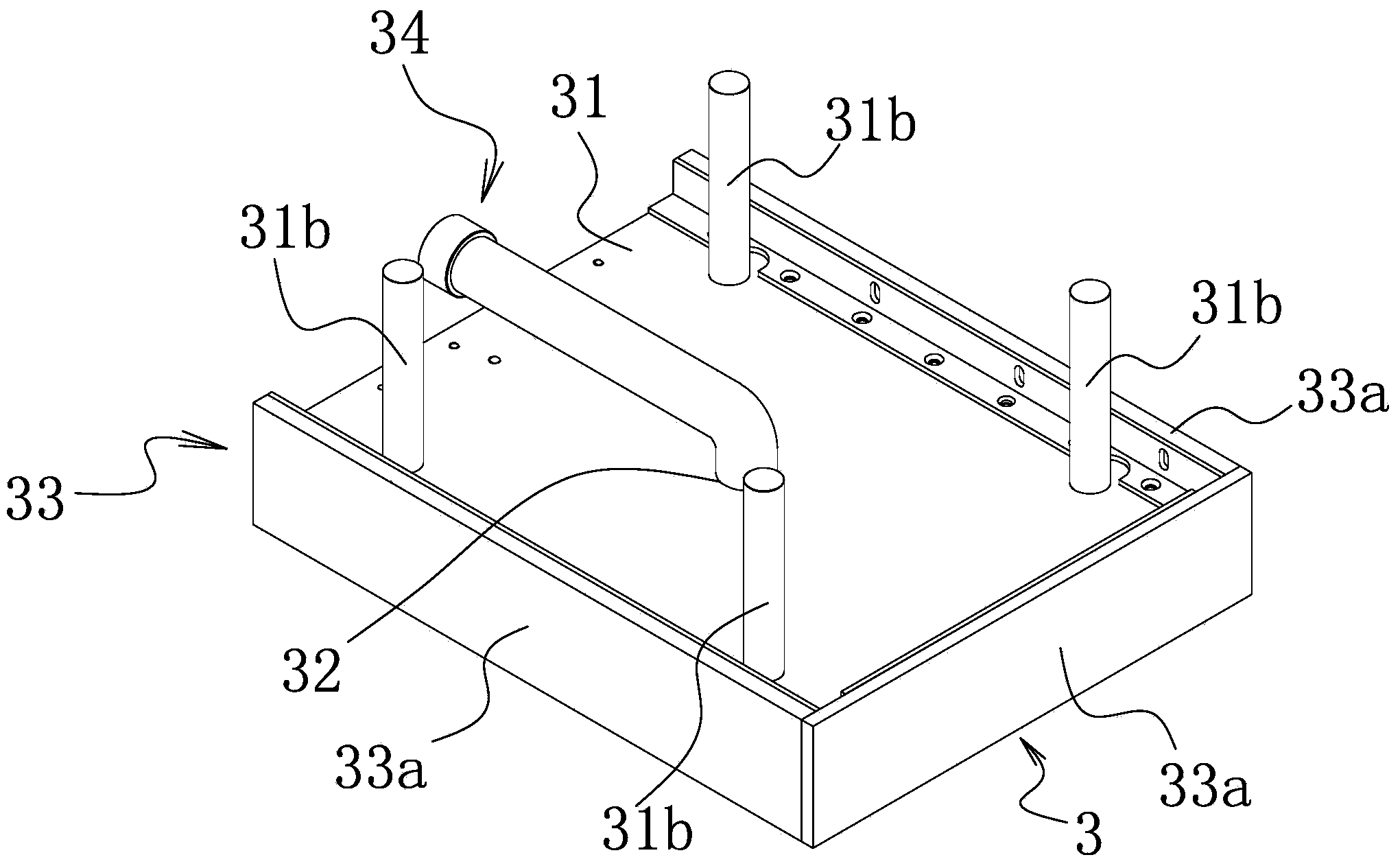

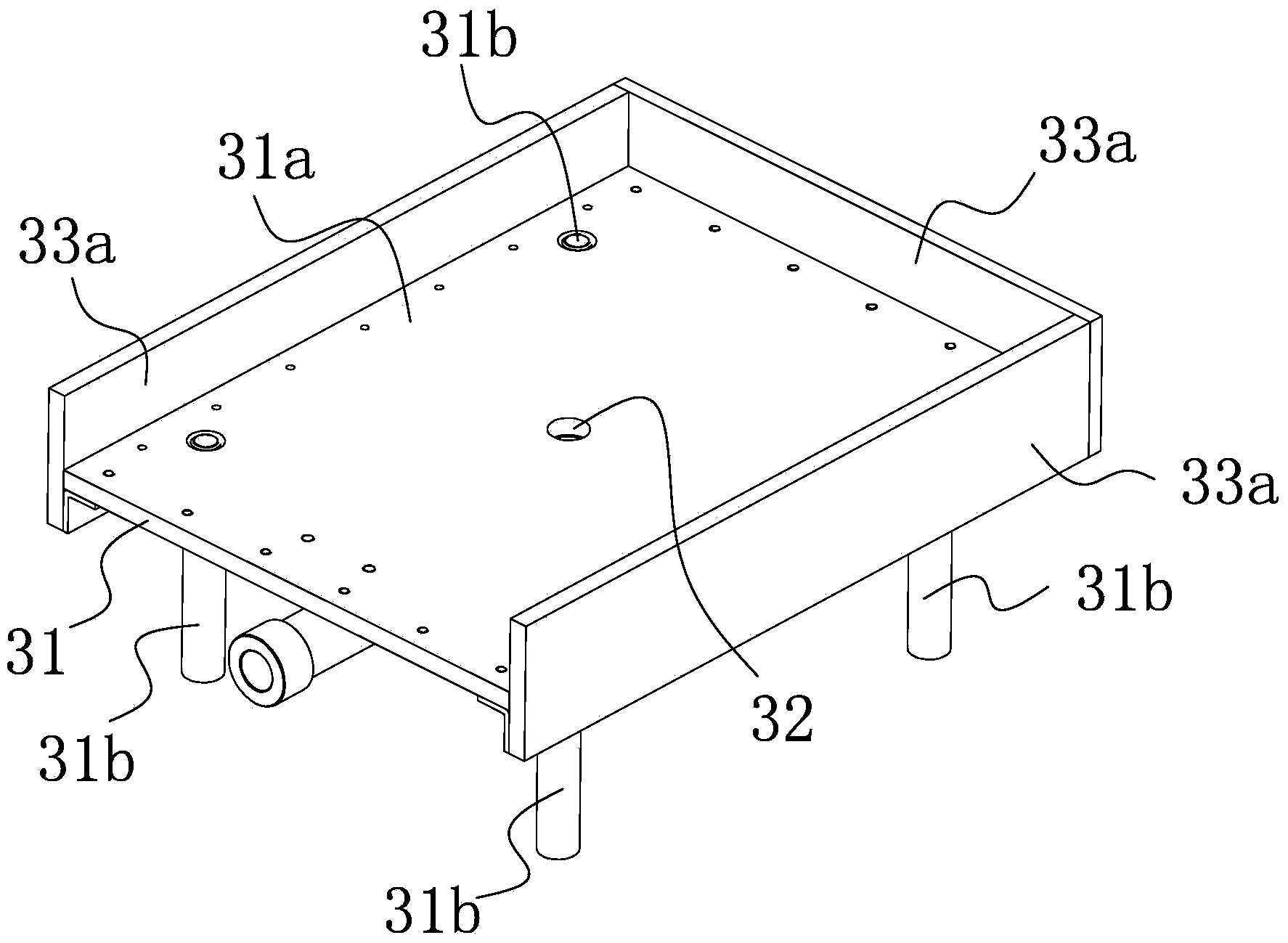

[0029] Such asfigure 1 with Image 6 As shown, the all-in-one machine for injecting and taking blanks of the automatic molding equipment includes a frame 1, and a plurality of rollers are arranged at the bottom of the frame 1. The frame 1 is provided with a movable frame 2, and a movable frame 2 is provided on the movable frame 2. The injection device 3 for injecting material into the forming mold a and the blank removal device 4 for obtaining and releasing the blank, and the movable frame 2 can drive the movable frame 2 to move so that the injection device 3 and the blank removal device 4 are alternately connected to the driving mechanism 5 directly above the molding die a.

[0030] In the optimized solution, the billet removal device 4 of this embodiment is arranged at the front end of the movable frame 2 , and the described materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com