A kind of yellow-brown near-infrared reflective heat insulation coating and preparation method thereof

A thermal insulation coating and near-infrared technology, which can be used in reflection/signal coatings, polyester coatings, coatings, etc., can solve problems such as poor reflection ability, and achieve the effects of low cost, easy availability of synthesis equipment and raw materials, and environmental friendliness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

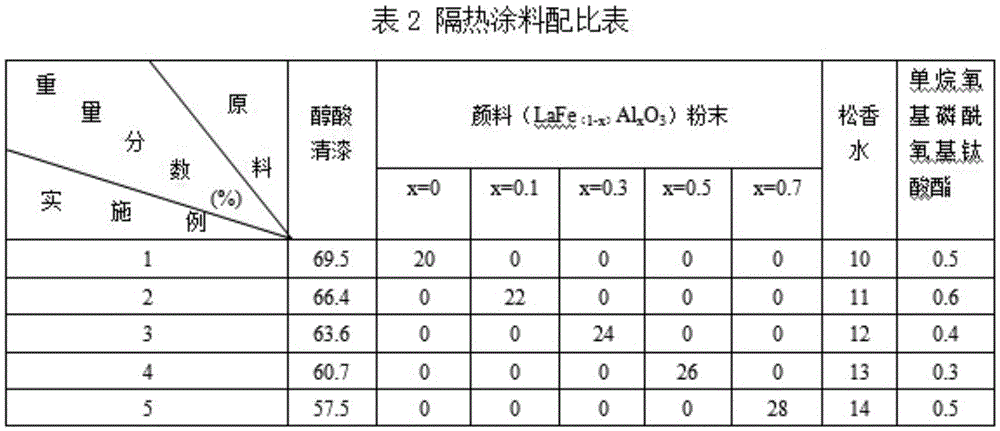

[0030] In order to facilitate those skilled in the art to further understand the present invention, the following examples are prepared according to the same preparation method.

[0031] First, prepare the near-infrared reflective pigment: mix the raw materials of the near-infrared reflective pigment, heat in a water bath, dry, and calcinate to obtain the near-infrared reflective pigment powder; wherein, the pigment raw materials are lanthanum nitrate hexahydrate, iron nitrate nonahydrate, aluminum nitrate nonahydrate, mono Hydrated citric acid, acrylamide, and glucose were all analytically pure commercially available. The ratio of pigment raw materials is as shown in Table 1, so that the general formula is LaFe (1-x) Al x o 3 powder, as shown in Table 1.

[0032] Then, mixing: according to the heat insulation coating ratio shown in Table 2, the film-forming material, solvent and additives are mixed and stirred evenly, and then the near-infrared reflective pigment is added ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com