Rotary double-stage compressor

A two-stage compressor, rotary technology, applied in the field of compressors, can solve the problem of small cylinder diameter two-stage compressors with small displacement, achieve the effect of improving compression capacity and compression displacement, and broadening the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

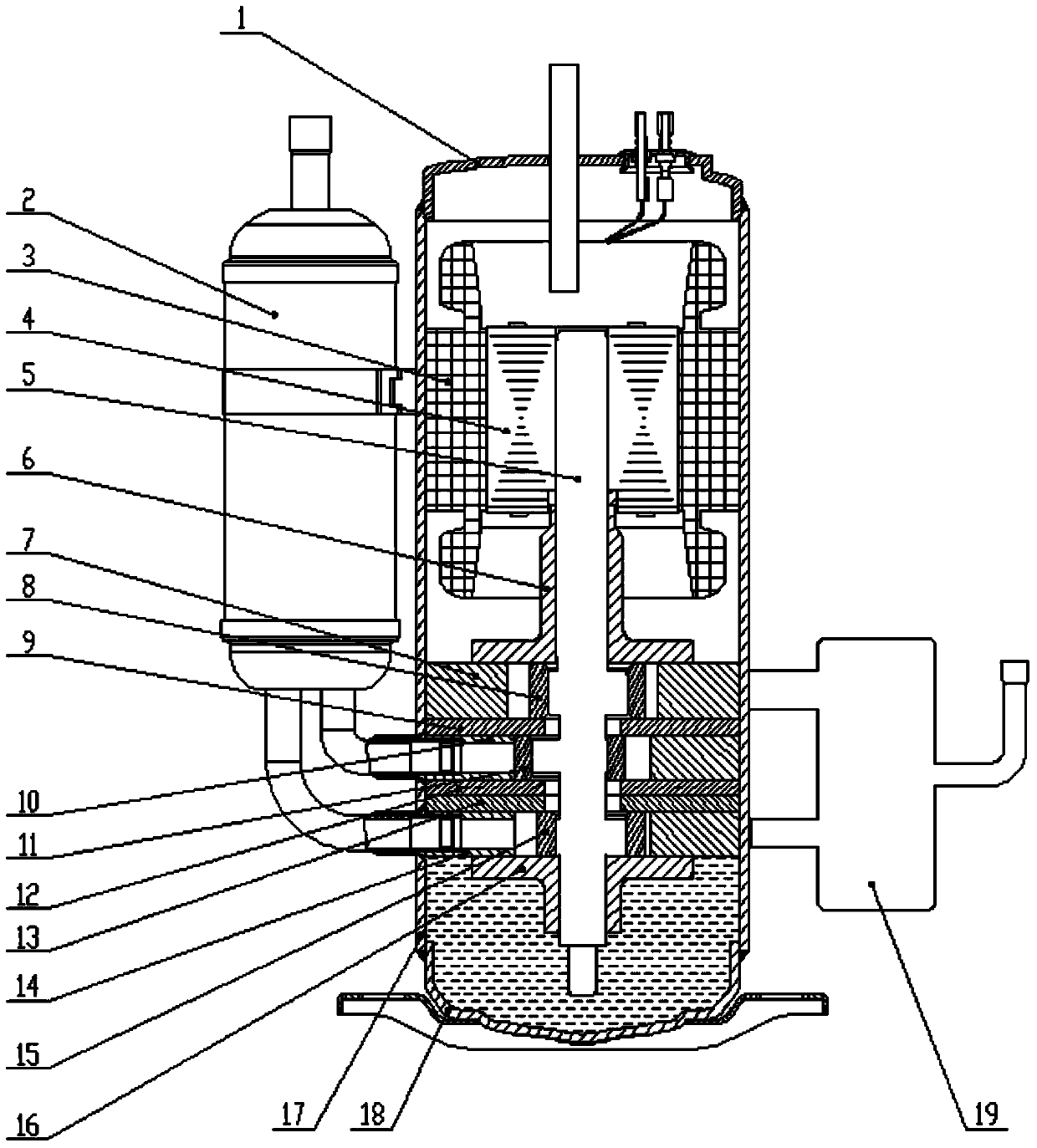

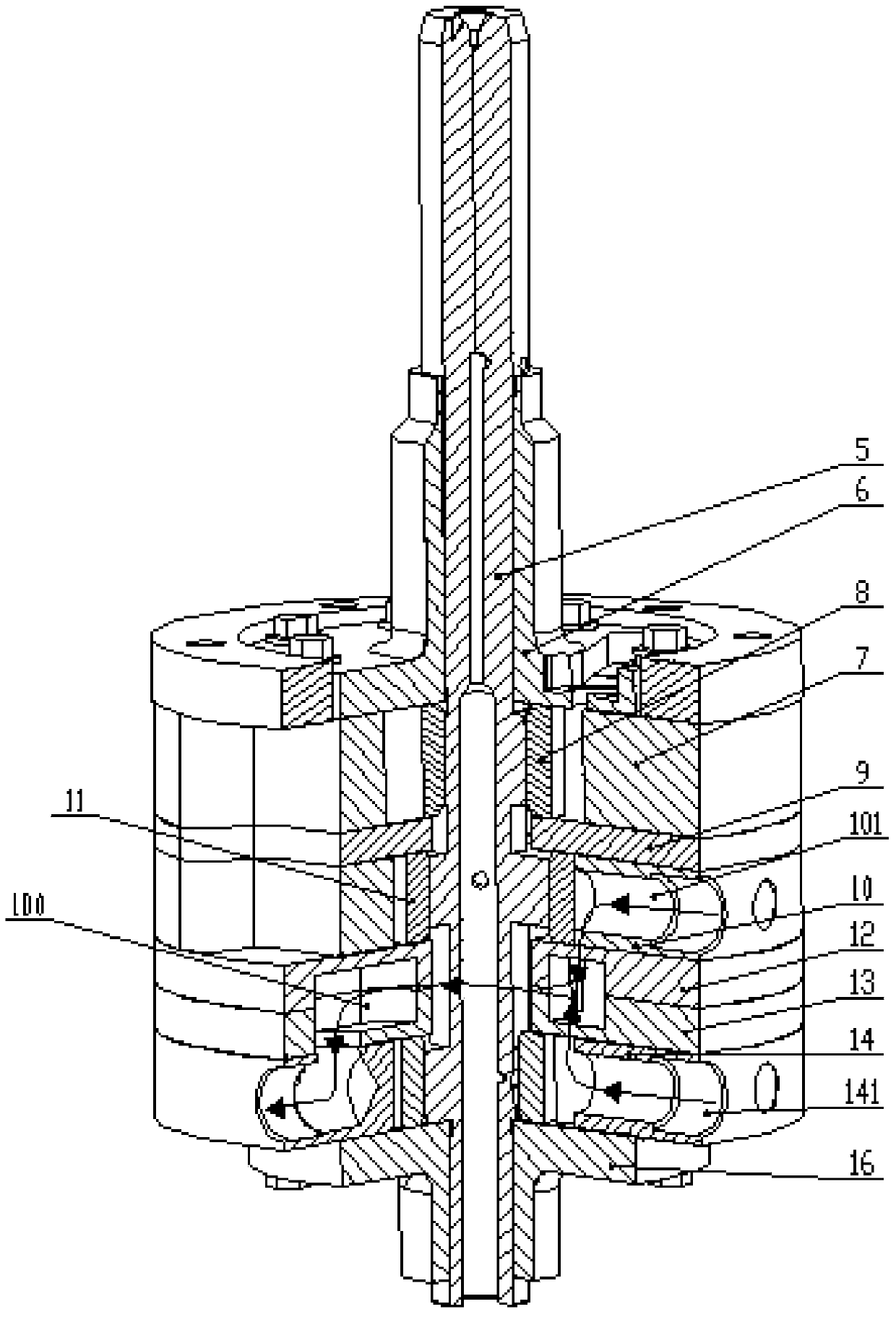

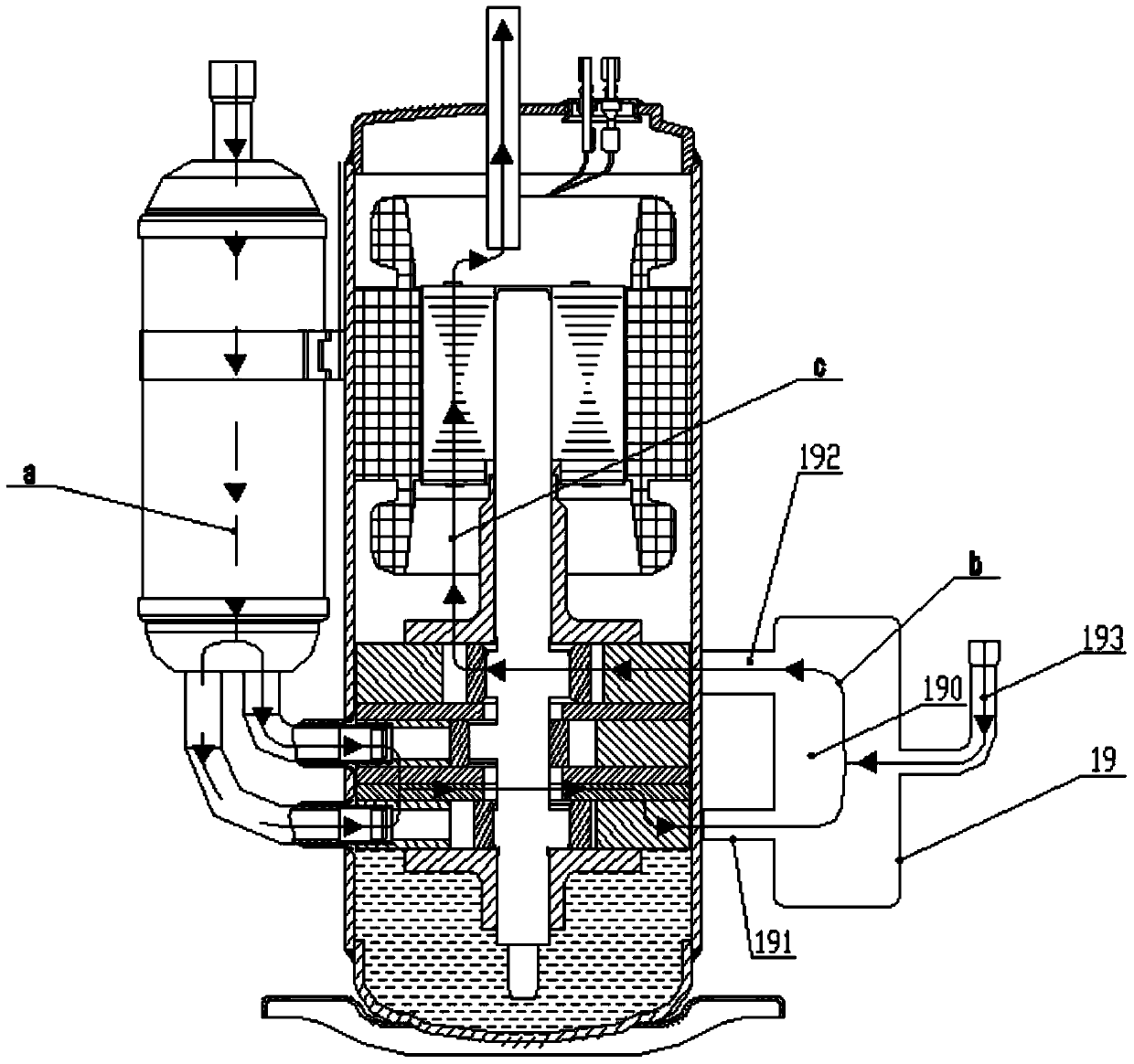

[0034] figure 1 , shows the specific structure of the rotary two-stage compressor of the present invention, including a shell surrounded by the upper cover assembly 1, the shell main body 17 and the lower cover 18 for accommodating the pump body, the pump body is fixed on the shell main body 17, and the motor The stator 3 is fixed to the main body of the casing, the rotor 4 drives the pump body through the crankshaft 5, the middle partition plate 9 isolates the high-pressure compression part and the low-pressure compression part stacked on the crankshaft 5 in sequence, and the upper flange 6 and the lower flange 16 are respectively set At both ends of the high-pressure compression section and the low-pressure compression section, the low-pressure compression section includes a first compression section composed of a first cylinder 14 and a first roller 15 and a second compression section composed of a second cylinder 10 and a second roller 11. part, the low-pressure partition ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com