Twisted tooth finned tube and finned tube heat exchange tube bundle

A technology of twisted finned tubes and finned tubes, which is applied in the field of finned tubes, can solve the problems of weak disturbance effect, poor heat transfer capacity enhancement effect of fin surface, and limited heat transfer enhancement effect of serrated spiral finned tubes, etc. Achieve the effect of increasing the finning ratio and reducing the difficulty of manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

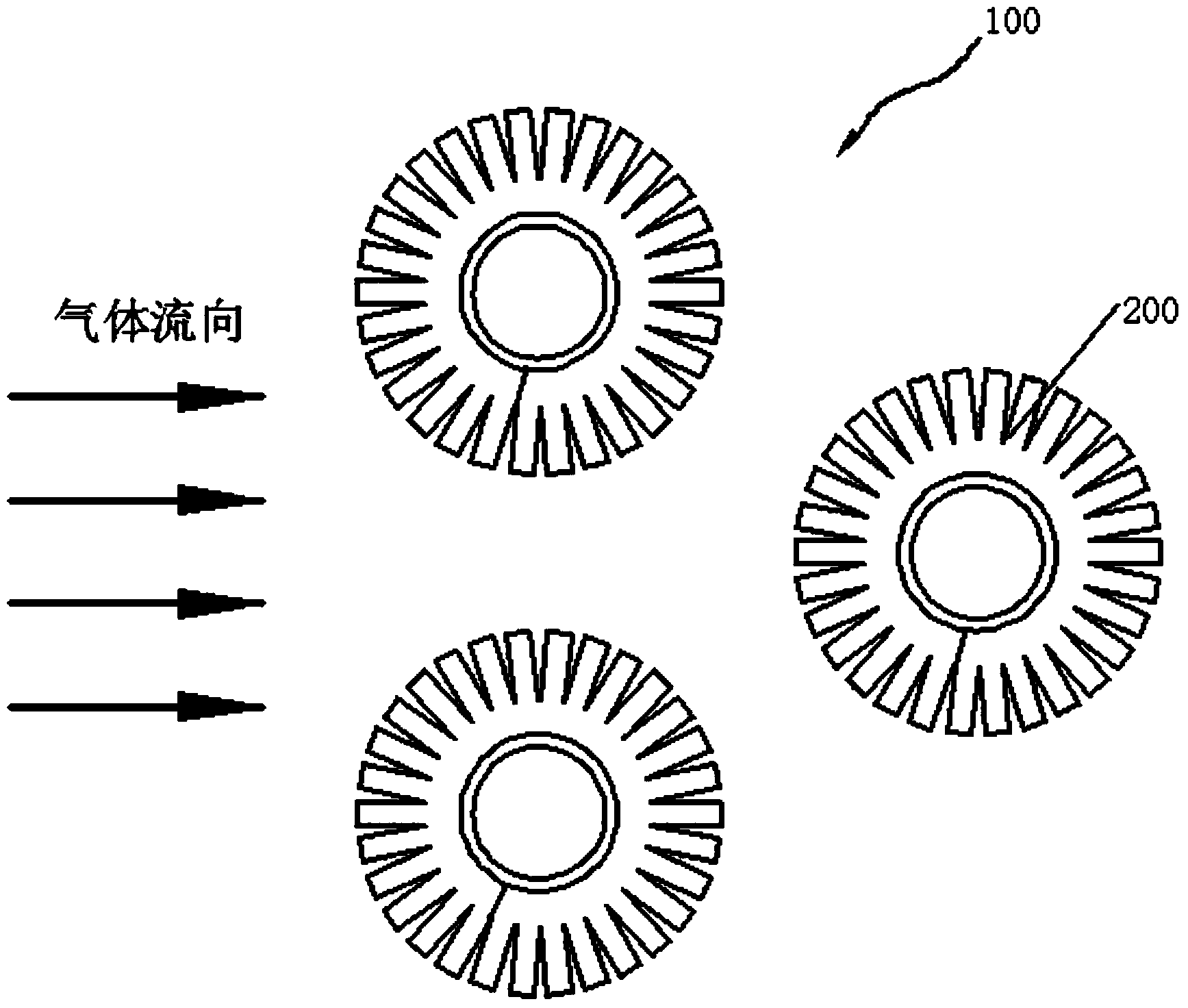

[0050] figure 1 It is a schematic structural view of the heat exchange tube bundle of finned tubes in Embodiment 1 of the present invention.

[0051] Such as figure 1 As shown, the finned tube heat exchange tube bundle 100 arranged in a staggered arrangement has three twisted finned tubes 200 arranged in two rows.

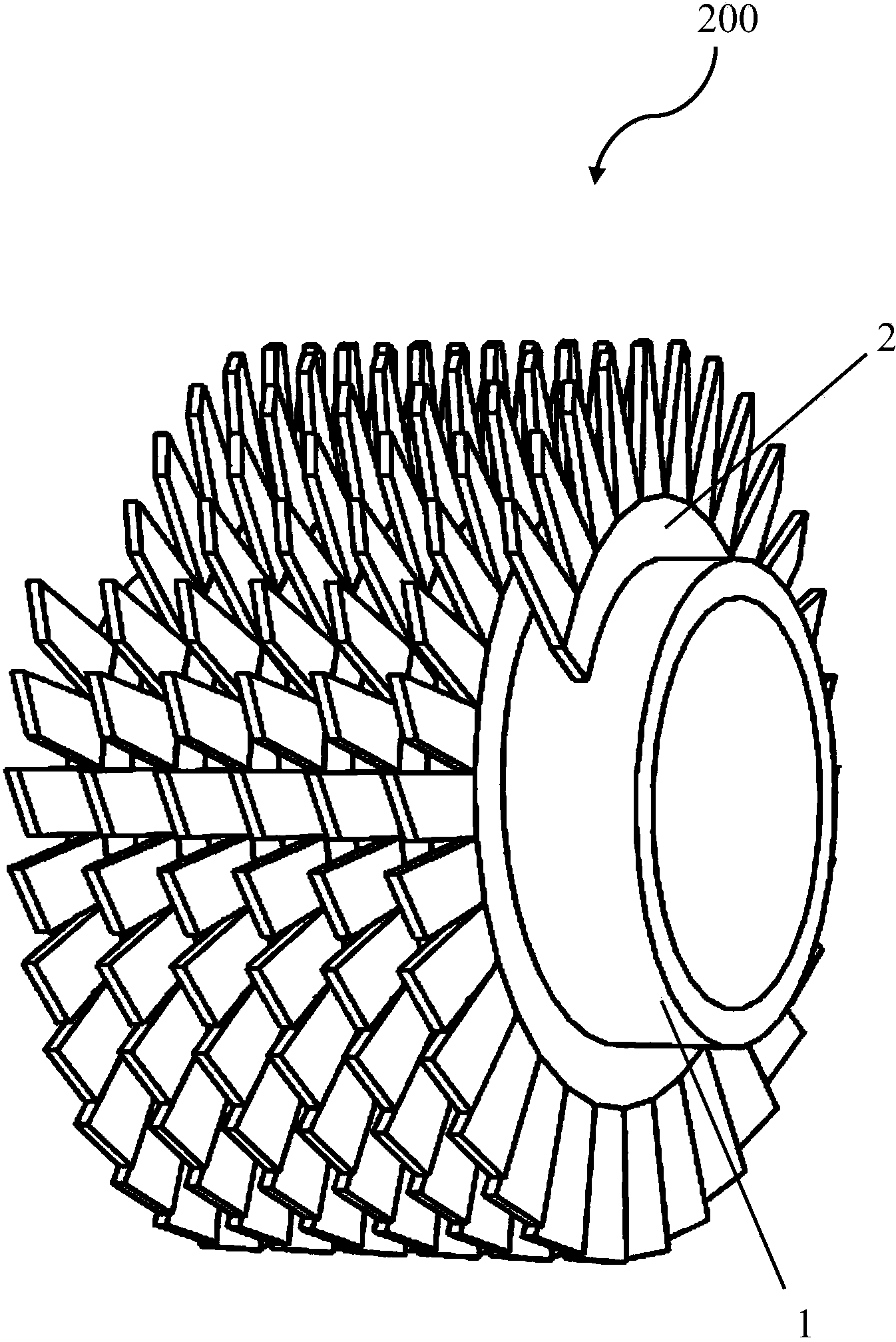

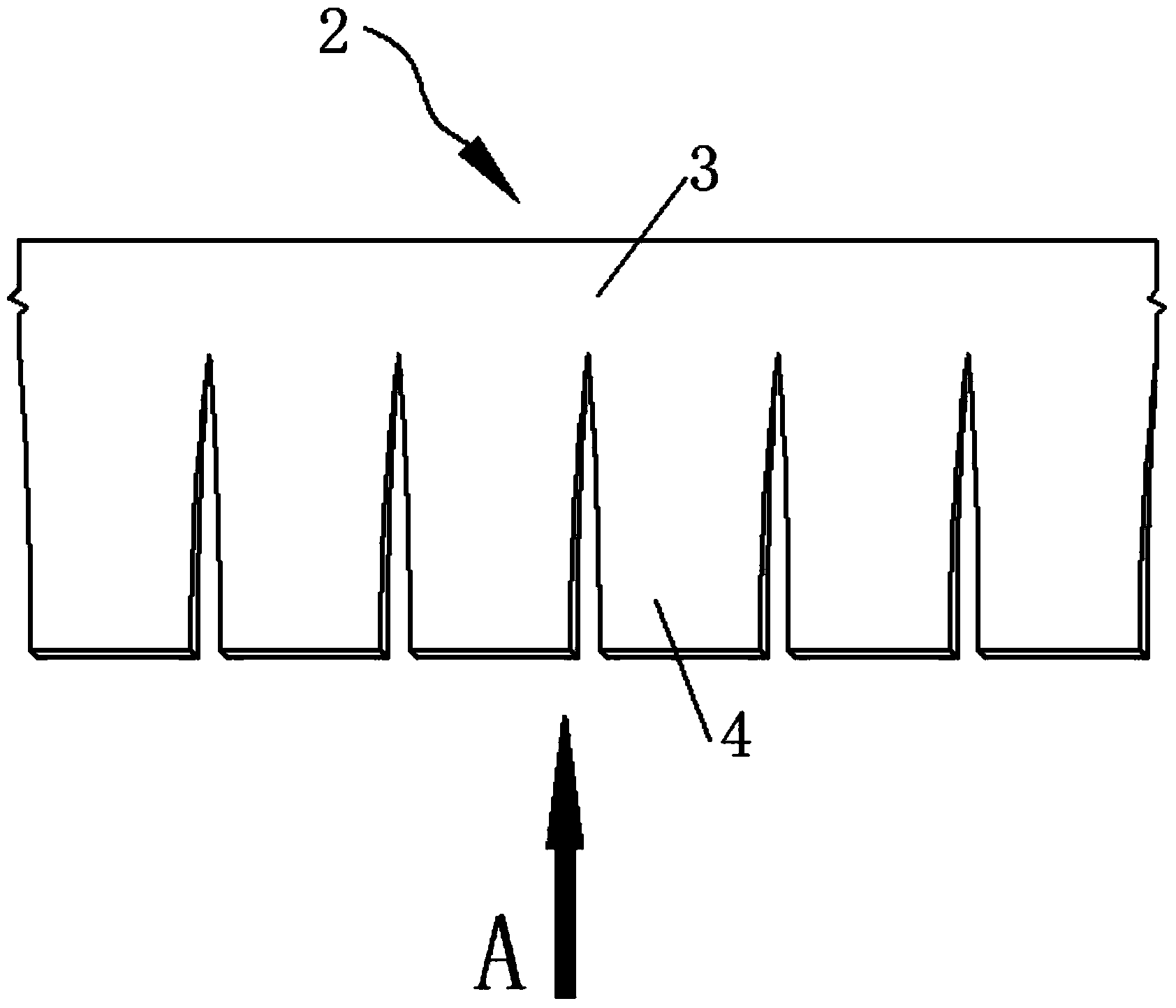

[0052] figure 2 It is a structural schematic diagram of the twisted-tooth finned tube in Embodiment 1 of the present invention.

[0053] Such as figure 2 As shown, the twisted finned tube 200 includes: a base tube part 1 and a finned part 2 .

[0054] The base pipe part 1 is in the shape of a circular pipe, and is filled with a flowing heat-exchange working medium. The fin portion 2 surrounds the outer wall of the base pipe portion 1 .

[0055] According to different applications, the diameter range of the base pipe part 1 can be between 10 mm and 1000 mm, and the radial length range of the fin part 2 can be between 5 mm and 200 mm. In order to obtain a lar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com