Exhaust pipe of magnetron for microwave oven

A magnetron and exhaust pipe technology, applied in the field of magnetron, can solve the problem of the deterioration of the electromagnetic compatibility characteristics of the magnetron used in microwave ovens, the inability of the exhaust pipe to effectively suppress the high-frequency harmonics of the magnetron, and the adverse effects of electrical components and other issues to achieve the effect of reducing adverse effects, avoiding the possibility of microwave leakage, and improving electromagnetic compatibility characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

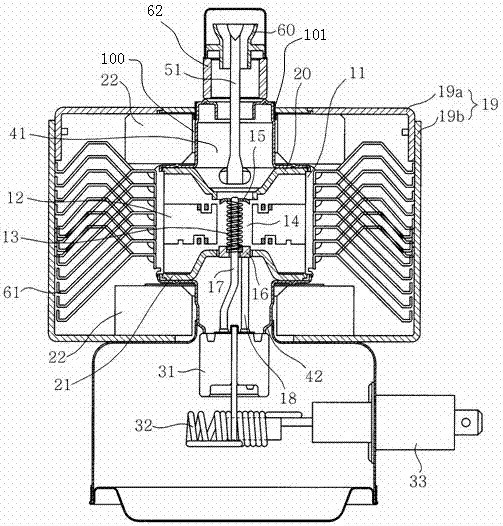

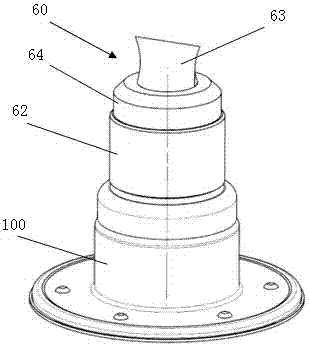

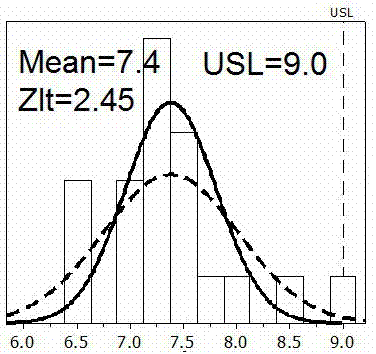

[0027] figure 1 It is a longitudinal sectional view of a magnetron structure in the prior art; figure 2 is a structural schematic diagram of the position of the magnetron exhaust pipe in the prior art; image 3 It is a schematic diagram of the 6δ management of the magnetron exhaust pipe in the prior art; Figure 4 is a schematic diagram of a magnetron exhaust pipe of the present invention; Figure 5 It is a schematic diagram of the 6δ management of the magnetron exhaust pipe of the present invention.

[0028] Such as Figure 4 As shown, the exhaust pipe of the magnetron for microwave ovens of the present invention includes a tubular body 63 and a fixed wall 64 extending outward from the outside of the pipe body and bending downward. The above-mentioned exhaust pipe 60 is fixedly arranged on the magnetic On the ceramic ring 62 above the antenna c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com