Multi-path output power supply

A multi-channel output and power supply technology, which is applied in the direction of output power conversion device, AC power input conversion to DC power output, electrical components, etc., can solve the safety problems of high transformer temperature, high duty cycle of power supply, and failure to pass safety regulations. Unable to detect problems such as overcurrent faults, to achieve the effect of improving electromagnetic compatibility characteristics and simple circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

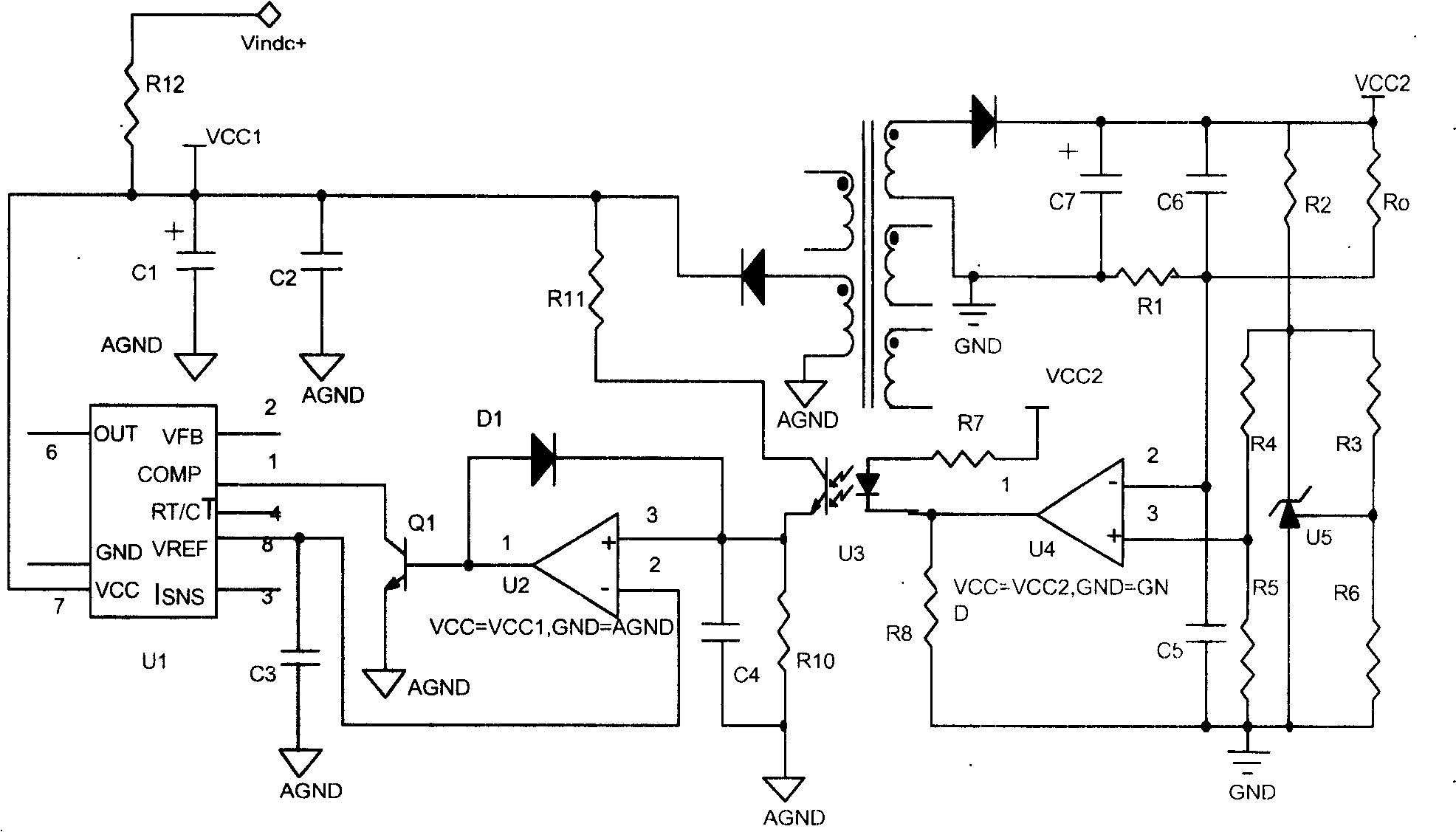

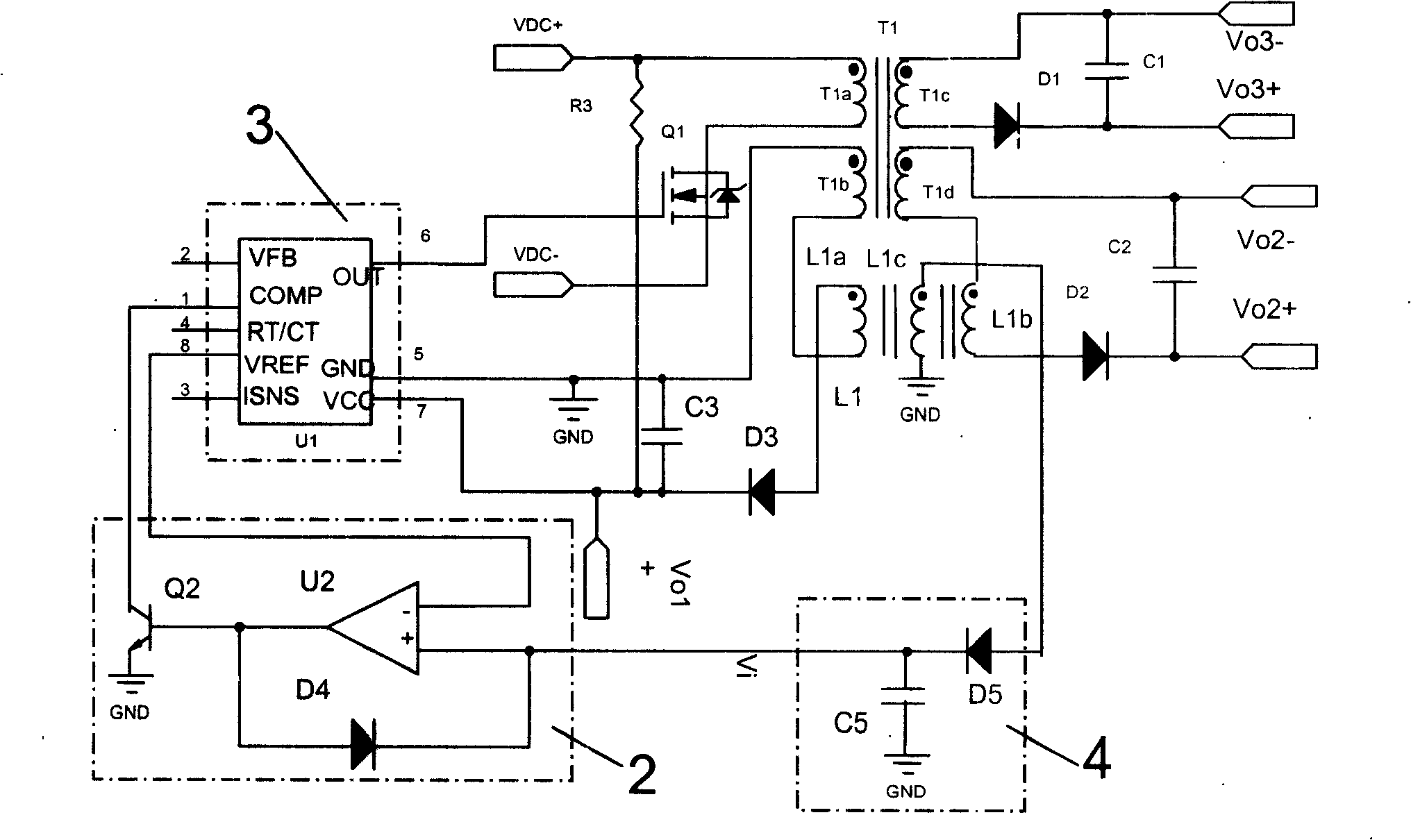

[0049] Such as figure 2 The multi-output power supply shown includes a transformer T1 , a voltage detection and comparison module 2 , and a power control module 3 . The transformer T1 has four windings, namely the first primary winding T1a, the second primary winding T1b, the first secondary winding T1c and the second secondary winding T1d. Among them, the first primary winding T1a corresponds to the input of the transformer T1, the second primary winding T1b, the first secondary winding T1c and the second secondary winding T1d correspond to the three output circuits of the transformer T1, which are Vo1 and Vo2 respectively. and Vo3 Road. Among them, Vo1 and Vo2 are auxiliary output roads, and they are also the output roads that we need to perform over-current or short-circuit protection. Vo3 road is the third output road, which can be the main output road or other auxiliary output roads.

[0050] We add a two-winding transformer in series in the output circuit before the r...

specific Embodiment approach 2

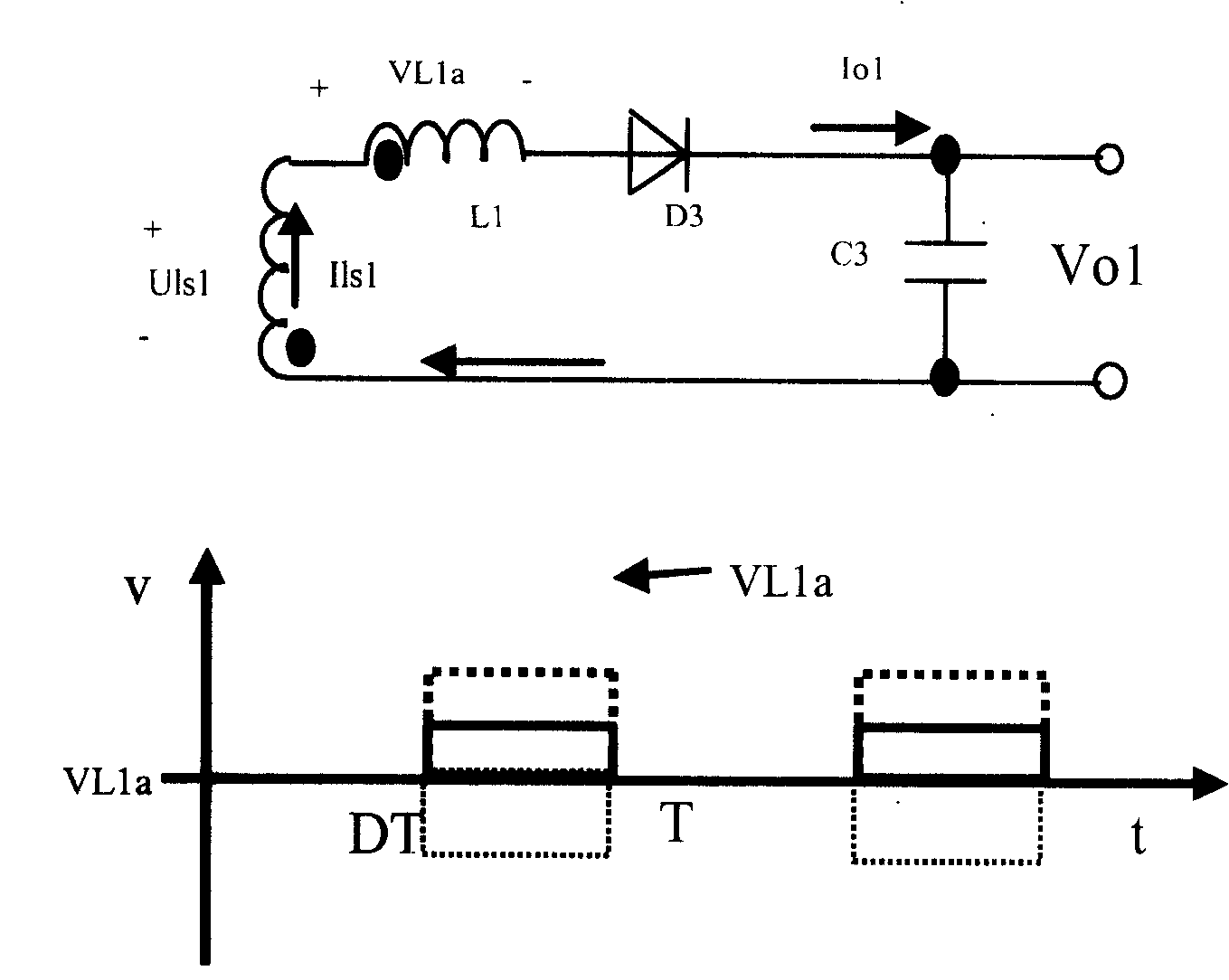

[0089] Such as Figure 4 As shown, the difference between this specific embodiment and specific embodiment 1 is that the multi-output power supply in this specific embodiment is a buck-type directional voltage regulation multi-output power supply. The current inflow ends of the first winding L1a and the second winding L1b have the same name as each other, that is, the magnetic fluxes generated by the two currents in the magnetic core of the transformer have the same direction, and the magnetic fluxes add up. The current inflow end of the detection winding L1c and the current inflow ends of the first winding L1a and the second winding L1b are opposite ends of each other.

[0090] After adding the transformer L1, the output voltage of Vo1, Vo2 and Vi voltage are respectively:

[0091] Vo1=ULs1(1-Ds)-AL×Na(Nb×ΔILs2+Na×ΔILs1)

[0092] Vo2=ULs2(1-Ds)-AL×Nb(Na×ΔILs1+Nb×ΔILs2)

[0093] Vi=AL×Nc(Nb×ΔILs2+Na×ΔILs1)

[0094] It can be seen from the above formula that the output volt...

specific Embodiment approach 3

[0099] Such as Figure 5 As shown, the difference between this specific embodiment and specific embodiment 1 is:

[0100] In this specific embodiment, a transformer with four windings is added, and the transformer includes a first winding L1a, a second winding L1b, a detection winding L1c and a third winding L1d, wherein the first winding L1a of the transformer is connected in series with the first auxiliary On the output path (Vo1 path), the second winding L1b is connected in series with the second auxiliary output path (Vo2 path), and the third winding L1d is connected in series with the third auxiliary output path (Vo3 path).

[0101] Apparently, by utilizing the technical idea of the present invention, it is also possible to perform directional voltage regulation on the output of more than three auxiliary output channels and at the same time perform overcurrent or short circuit protection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com